Abstract

The carbon source adopted in deposition processes of bias-enhanced hot filament chemical vapor deposition diamond films has significant influences on basic, mechanical and tribological properties of as-deposited films. In the present study, pristine microcrystalline diamond (MCD) films are deposited on both WC-6 wt% Co flat and drawing die substrates, using the same deposition parameters and four typical carbon sources, including the methane, acetone, methanol and the ethanol. As-obtained MCD-coated and WC–Co flat specimens are all applied for standard tribotests, systematically analyzing the typical stages of their friction coefficient curves as functions of the sliding time, differences between tribological properties of MCD films deposited using different carbon sources, as well as effects of the normal load and the sliding velocity adopted in the test, which are closely related to their surface features, composition transformations and mechanical properties. Moreover, MCD-coated and WC–Co drawing die specimens are applied for special-designed wear tests in order to compare their wear rates and removal times, further clarifying the material removal mechanisms, as well as similarities and differences compared with actual applications of diamond-coated drawing dies.

Similar content being viewed by others

References

Shen, B., Sun, F., Xue, H., Chen, M., Zhang, Z.: Study on fabrication and cutting performance of high quality diamond coated PCB milling tools with complicated geometries. Surf. Eng. 25, 70–76 (2009)

Ma, Y., Sun, F., Xue, H., Zhang, Z., Chen, M.: Deposition and characterization of nanocrystalline diamond films on Co-cemented tungsten carbide inserts. Diam. Relat. Mater. 16, 481–485 (2007)

Zhang, Z., Shen, H., Sun, F., He, X., Wan, Y.: Fabrication and application of chemical vapor deposition diamond-coated drawing dies. Diam. Relat. Mater. 10, 33–38 (2001)

Wang, X.C., Shen, B., Sun, F.H., Zhang, Z.M., Shen, H.S., Guo, S.S.: Deposition and application of CVD diamond films on the interior-hole surface of silicon carbide compacting dies. Key Eng. Mater. 499, 45–50 (2012)

Tomé, M.A., Fernandes, A.J.S., Oliveira, F.J., Silva, R.F., Carrapichano, J.M.: High performance sealing with CVD diamond self-mated rings. Diam. Relat. Mater. 14, 617–621 (2005)

Perle, M., Bareiss, C., Rosiwal, S.M., Singer, R.F.: Generation and oxidation of wear debris in dry running tests of diamond coated SiC bearings. Diam. Relat. Mater. 15, 749–753 (2006)

Wolden, C., Mitra, S., Gleason, K.K.: Radiative heat transfer in hot-filament chemical vapor deposition diamond reactors. J. Appl. Phys. 72, 3750–3758 (1992)

Polini, R., Santarelli, M., Traversa, E.: Nucleation and adhesion of diamond films on Co cemented tungsten carbide. J. Electrochem. Soc. 146, 4490–4498 (1999)

Liu, Y.K., Tso, P.L., Lin, I.N., Tzeng, Y., Chen, Y.C.: Comparative study of nucleation processes for the growth of nanocrystalline diamond. Diam. Relat. Mater. 15, 234–238 (2006)

Abreu, C.S., Amaral, M., Oliveira, F.J., Gomes, J.R., Silva, R.F.: HFCVD nanocrystalline diamond coatings for tribo-applications in the presence of water. Diam. Relat. Mater. 18, 271–275 (2009)

Konicek, A.R., Grierson, D.S., Gilbert, P., Sawyer, W.G., Sumant, A.V., Carpick, R.W.: Origin of ultralow friction and wear in ultrananocrystalline diamond. Phys. Rev. Lett. 100, 4 (2008)

Amaral, M., Abreu, C.S., Oliveira, F.J., Gomes, J.R., Silva, R.F.: Tribological characterization of NCD in physiological fluids. Diam. Relat. Mater. 17, 848–852 (2008)

Erdemir, A., Fenske, G.R., Krauss, A.R., Gruen, D.M., McCauley, T., Csencsits, R.T.: Tribological properties of nanocrystalline diamond films. Surf. Coat. Technol. 120–121, 565–572 (1999)

Wang, L., Lei, X., Shen, B., Sun, F., Zhang, Z.: Tribological properties and cutting performance of boron and silicon doped diamond films on Co-cemented tungsten carbide inserts. Diam. Relat. Mater. 33, 54–62 (2013)

Liang, Q., Stanishevsky, A., Vohra, Y.K.: Tribological properties of undoped and boron-doped nanocrystalline diamond films. Thin Solid Films 517, 800–804 (2008)

Wang, X., Wang, L., Shen, B., Sun, F.: Friction and wear performance of boron doped, undoped microcrystalline and fine grained composite diamond films. Chin. J. Mech. Eng. 28, 155–163 (2015)

Shen, B., Sun, F.: Effect of surface morphology on the frictional behaviour of hot filament chemical vapour deposition diamond films. Proc. Inst. Mech. Eng. J. Eng. Tribol. 223, 1–11 (2009)

Shen, B., Sun, F.H.: Deposition and friction properties of ultra-smooth composite diamond films on Co-cemented tungsten carbide substrates. Diam. Relat. Mater. 18, 238–243 (2009)

Takeno, T., Komoriya, T., Nakamori, I., Miki, H., Abe, T., Uchimoto, T., Takagi, T.: Tribological properties of partly polished diamond coatings. Diam. Relat. Mater. 14, 2118–2121 (2005)

Pimenov, S.M., Smolin, A.A., Obraztsova, E.D., Konov, V.I.: Tribological behaviour of smooth diamond films. Surf. Coat. Technol. 77, 572–578 (1995)

Bogli, U., Blatter, A., Pimenov, S.M., Obraztsova, E.D., Smolin, A.A., Maillat, M., Leijala, A., Burger, J., Hintermann, H.E., Loubnin, E.N.: Tribological properties of smooth polycrystalline diamond films. Diam. Relat. Mater. 4, 1009–1019 (1995)

Wang, X., Zhang, J., Shen, B., Zhang, T., Sun, F.: Fracture and solid particle erosion of micro-crystalline, nano-crystalline and boron-doped diamond films. Int. J. Refract. Met. Hard Mater. 45, 31–40 (2014)

Dumpala, R., Chandran, M., Kumar, N., Dash, S., Ramamoorthy, B., Rao, M.S.R.: Growth and characterization of integrated nano- and microcrystalline dual layer composite diamond coatings on WC–Co substrates. Int. J. Refract. Met. Hard Mater. 37, 127–133 (2013)

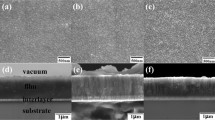

Wang, X., Zhao, T., Sun, F., Shen, B.: Comparisons of HFCVD diamond nucleation and growth using different carbon sources. Diam. Relat. Mater. 54, 26–33 (2015)

Kobashi, K., Nishimura, K., Kawate, Y., Horiuchi, T.: Synthesis of diamonds by use of microwave plasma chemical-vapor deposition: morphology and growth of diamond films. Phys. Rev. B 38, 4067–4084 (1988)

Spitsyn, B.V., Bouilov, L.L., Derjaguin, B.V.: Vapor growth of diamond on diamond and other surfaces. J. Cryst. Growth 52(Part 1), 219–226 (1981)

Liou, Y., Inspektor, A., Weimer, R., Knight, D., Messier, R.: The effect of oxygen in diamond deposition by microwave plasma enhanced chemical vapor deposition. J. Mater. Res. 5, 2305–2312 (1990)

Belmonte, M.: Diamond coating of coloured Si3N4 ceramics. Diam. Relat. Mater. 14, 54–59 (2005)

Wang, X., Zhang, T., Shen, B., Zhang, J., Sun, F.: Simulation and experimental research on the substrate temperature distribution in HFCVD diamond film growth on the inner hole surface. Surf. Coat. Technol. 219, 109–118 (2013)

Lin, Z., Shen, B., Sun, F., Zhang, Z., Guo, S.: Numerical and experimental investigation of trapezoidal wire cold drawing through a series of shaped dies. Int. J. Adv. Manuf. Technol. 76, 1383–1391 (2015)

Lin, Z., Shen, B., Sun, F., Zhang, Z., Guo, S.: Diamond-coated tube drawing die optimization using finite element model simulation and response surface methodology. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 228, 1432–1441 (2014)

Salgueiredo, E., Amaral, M., Neto, M.A., Fernandes, A.J.S., Oliveira, F.J., Silva, R.F.: HFCVD diamond deposition parameters optimized by a Taguchi Matrix. Vacuum 85, 701–704 (2011)

Shipway, P.H., Hutchings, I.M.: The role of particle properties in the erosion of brittle materials. Wear 193, 105–113 (1996)

Hollman, P., Wanstrand, O., Hogmark, S.: Friction properties of smooth nanocrystalline diamond coatings. Diam. Relat. Mater. 7, 1471–1477 (1998)

Grillo, S.E., Field, J.E.: The friction of CVD diamond at high Hertzian stresses: the effect of load, environment and sliding velocity. J. Phys. D Appl. Phys. 33, 595–602 (2000)

Straffelini, G., Scardi, P., Molinari, A., Polini, R.: Characterization and sliding behavior of HFCVD diamond coatings on WC-Co. Wear 249, 461–472 (2001)

Rabinowicz, E.: Friction and Wear of Materials. Wiley, New York (1995)

Bhushan, B., Jahsman, W.E.: Measurement of dynamic material behavior under nearly uniaxial strain conditions. Int. J. Solids Struct. 14, 739–753 (1978)

Bhushan, B., Jahsman, W.E.: Propagation of weak waves in elastic–plastic and elastic–viscoplastic solids with inerfaces. Int. J. Solids Struct. 14, 39–51 (1978)

Acknowledgments

This research is supported by the National Natural Science Foundation of China (Nos. 51275302, 51375011) and China Postdoctoral Science Foundation (No. 15Z102060056).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, X., Shen, X., Sun, F. et al. Tribological Properties of MCD Films Synthesized Using Different Carbon Sources When Sliding Against Stainless Steel. Tribol Lett 61, 21 (2016). https://doi.org/10.1007/s11249-015-0639-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0639-6