Abstract

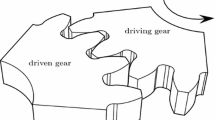

This study investigates the impacts of the angular misalignment that is tangent to the plane of action of spur gears on the contact fatigue life of micro-pitting crack nucleation using a computational approach. The governing equations of the mixed elastohydrodynamic lubrication are solved to determine the surface traction distributions. A boundary element-based near-surface stress formulation is implemented for the computation of the multi-axial stress fields, capturing the influence of the local surface roughness topography on the stress concentrations. A fatigue criterion is then used to assess the fatigue damage. The method of circular crown in the lead direction of the gear pair is proposed to alleviate the tooth surface load and lengthen the fatigue life under the misalignment condition. It is shown there exists an optimized crown magnitude, which is dependent on both the misalignment amount and the input torque of the gear pair, for the fatigue life improvement.

Similar content being viewed by others

References

Cheng, W., Cheng, H.S.: Effect of surface roughness orientation on pitting resistance of lubricated rollers. Tribol. Trans. 38, 396–402 (1995)

Webster, M.N., Norbart, C.J.J.: An experimental investigation of micropitting using a roller disk machine. Tribol. Trans. 38, 883–895 (1995)

Oila, A., Bull, S.J.: Assessment of the factors influencing micropitting in rolling/sliding contacts. Wear 258, 1510–1524 (2005)

Winkelmann, L., El-Saeed, O., Bell, M.: The effect of superfinishing on gear micropitting. Gear Technol. 2, 60–65 (2009)

Morales-Espejel, G.E., Brizmer, V.: Micropitting modeling in rolling-sliding contacts: application to roller bearings. Tribol. Trans. 54, 625–643 (2011)

Li, S., Kahraman, A.: Micro-pitting fatigue lives of lubricated point contacts: experiments and model validation. Int. J. Fatigue 48, 9–18 (2013)

Evans, H.P., Snidle, R.W., Sharif, K.J., Shaw, B.A., Zhang, J.: Analysis of micro-elastohydrodynamic lubrication and prediction of surface fatigue damage in micropitting tests on helical gears. J. Tribol. 135, 011501–011509 (2013)

Olver, A.V., Tiew, L.K., Medina, S., Choo, J.W.: Direct observations of a micropit in an elastohydrodynamic contact. Wear 256, 168–175 (2004)

Winter, H., Weiss, T.: Some factors influencing the pitting, micro-pitting (frosted areas) and slow speed wear of surface hardened gears. ASME J. Mech. Des. 103, 499–505 (1981)

Brechot, P., Cardis, A.B., Murphy, W.R., Theissen, J.: Micropitting resistant industrial gear oils with balanced performance. Ind. Lubr. Tribol. 52, 125–136 (2000)

Lainé, E., Olver, A.V., Beveridge, T.A.: Effect of lubricants on micropitting and wear. Tribol. Int. 41, 1049–1055 (2008)

Ahlroos, T., Ronkainen, H., Helle, A., Prikka, R., Virta, J., Varjus, S.: Twin disc micropitting tests. Tribol. Int. 42, 1460–1466 (2009)

Oila, A., Shaw, B.A., Aylott, C.J., Bull, S.J.: Martensite decay in micropitted gears. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 219, 77–83 (2005)

Li, S.: A boundary element model for near surface contact stresses of rough surfaces. Comput. Mech. 54, 833–846 (2014)

Li, S., Kahraman, A.: A physics-based model to predict micro-pitting lives of lubricated point contacts. Int. J. Fatigue 47, 205–215 (2013)

Li, S., Kahraman, A.: A micro-pitting model for spur gear contacts. Int. J. Fatigue 59, 224–233 (2014)

Li, S.: A computational study on the influence of surface roughness lay directionality on micropitting of lubricated point contacts. ASME J. Tribol. 137, 021401–021410 (2015)

Houser, D.R., Harianto, J., Talbot, D.: Gear mesh misalignment. Gear Solut. 6, 34–43 (2006)

Cheng, W., Cheng, H.S., Mura, T., Keer, L.M.: Micromechanics modeling of crack initiation under contact fatigue. J. Tribol. 116, 2–8 (1994)

Li, S., Kahraman, A., Anderson, N.E., Wedeven, L.D.: A model to predict scuffing failures of a ball-on-disk contact. Tribol. Int. 60, 233–245 (2013)

Li, S.: Influence of surface roughness lay directionality on scuffing failure of lubricated point contacts. ASME J. Tribol. 135, 041502–041510 (2013)

Li, S.: A thermal tribo-dynamic mechanical power loss model for spur gear pairs. Tribol. Int. 88, 170–178 (2015)

Li, S., Kahraman, A.: Influence of dynamic behavior on elastohydrodynamic lubrication of spur gears. J. Eng. Tribol. 225, 740–753 (2011)

Li, S., Kahraman, A.: A spur gear mesh interface damping model based on elastohydrodynamic contact behaviour. Int. J. Powertrains 1, 4–21 (2011)

Li, S., Kahraman, A.: A tribo-dynamic model of a spur gear pair. J. Sound Vib. 332, 4963–4978 (2013)

LDP, Gear Load Distribution Program: Gear and Power Transmission Research Laboratory. The Ohio State University, Columbus (2012)

Li, S., Kahraman, A.: A transient mixed elastohydrodynamic lubrication model for spur gear pairs. J. Tribol. 132, 011501–011509 (2010)

Conry, T.F., Seireg, A.: A mathematical programming technique for the evaluation of load distribution and optimal modifications for gear systems. J. Eng. Ind. 95, 1115–1122 (1973)

Li, S., Kahraman, A.: Prediction of spur gear mechanical power losses using a transient elastohydrodynamic lubrication model. Tribol. Trans. 53, 554–563 (2010)

Li, S., Kahraman, A., Klein, M.: A fatigue model for spur gear contacts operating under mixed elastohydrodynamic lubrication conditions. ASME J. Mech. Des. 134, 041007–041011 (2012)

Li, S., Kahraman, A.: A mixed EHL model with asymmetric integrated control volume discretization. Tribol. Int. 42, 1163–1172 (2009)

Li, S., Kahraman, A.: A method to derive friction and rolling power loss formulae for mixed EHL contacts. J. Adv. Mech. Des. Syst. Manuf. 5, 252–263 (2011)

Johnson, K.J.: Contact Mechanics. Cambridge University Press, Cambridge (1985)

Epstein, D., Keer, L.M., Wang, Q.J., Cheng, H.S., Zhu, D.: Effect of surface topography on contact fatigue in mixed lubrication. Tribol. Trans. 46, 506–513 (2003)

Zhu, D., Ren, N., Wang, Q.J.: Pitting life prediction based on a 3D line contact mixed EHL analysis and subsurface von Mises stress calculation. ASME J. Tribol. 131, 041501 (2009)

Li, S., Kahraman, A.: A fatigue model for contacts under mixed elastohydrodynamic lubrication condition. Int. J. Fatigue 33, 427–436 (2011)

Qiao, H., Evans, H.P., Snidle, R.W.: Comparison of fatigue model results for rough surface elastohydrodynamic lubrication. J. Eng. Tribol. 222, 381–391 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, S. An Investigation on the Influence of Misalignment on Micro-pitting of a Spur Gear Pair. Tribol Lett 60, 35 (2015). https://doi.org/10.1007/s11249-015-0613-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0613-3