Abstract

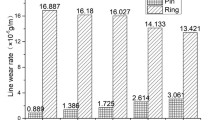

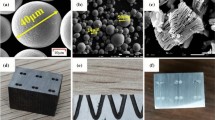

The friction and deformation behaviors of ~60-μm-diameter stainless steel micro-balls were assessed under various rolling conditions against Si specimens. In the friction tests, the micro-balls were placed between a stationary flat silicon specimen on the top and a flat or grooved silicon specimen at the bottom that was made to move in a reciprocating motion. Rectangular- and V-shaped grooves were fabricated on the silicon specimen by a photolithographic process, and the effect of groove shape on the frictional behavior of the micro-balls was investigated. Friction coefficient of 0.01 could be successfully achieved when proper rolling was attained. It was found that the number of micro-balls was not a critical factor as long as more than three balls were placed between the two flat Si specimens. Furthermore, rectangular-shaped groove resulted in lower friction than V-shaped groove. This was due to severe deformation of the micro-ball which led to increase in the contact area when the V-shaped groove was used. The results of this work were expected to aid in the development of miniature bearings for applications in small precision systems.

Similar content being viewed by others

References

Harris, T.A., Mindel, M.H.: Rolling element bearing dynamics. Wear 23, 311–317 (1973)

Jacobson, B.: History of rolling bearings. Tribol. Online 6, 155–159 (2011)

Moerlooze, K.D., Al-Bender, F., Brussel, H.V.: Modeling of the dynamic behavior of systems with rolling elements. Int. J. Nonlinear Mech. 46, 222–233 (2011)

Lin, C.W., Lin, Y.K., Chu, C.H.: Dynamic models and design of spindle-bearing systems of machine tools: a review. Int. J. Precis. Eng. Manuf. 14, 513–521 (2013)

Kim, S.H., Asay, D.B., Dugger, M.T.: Nanotribology and MEMS. Nano Today 2, 22–29 (2007)

Mouboudian, R., Ashurst, W.R., Carraro, C.: Tribological challenges in micromechanical systems. Tribol. Lett. 12, 95–100 (2002)

Van Spengen, W.M.: MEMS reliability from a failure mechanisms perspective. Microelectron. Reliab. 43, 1049–1060 (2003)

Williams, J.A., Le, H.R.: Tribology and MEMS. J. Phys. D Appl. Phys. 39, R201–R214 (2006)

Donneta, C., Erdemir, A.: Solid lubricant coatings: recent developments and future trends. Tribol. Lett. 17, 389–397 (2004)

Zhu, L.N., Wang, C.B., Wang, H.D., Xu, B.S., Zhuang, D.M., Liu, J.J., Li, G.L.: Microstructure and tribological properties of WS2/MoS2 multilayer films. Appl. Surf. Sci. 258, 1944–1948 (2012)

Myshkin, N.K., Petrokovets, M.I., Kovalev, A.V.: Tribology of polymers: adhesion, friction, wear, and mass-transfer. Tribol. Int. 38, 910–921 (2005)

Lua, X., Wong, K.C., Wong, P.C., Mitchell, K.A.R., Cotter, J., Eadie, D.T.: Surface characterization of polytetrafluoroethylene (PTFE) transfer films during rolling–sliding tribology tests using X-ray photoelectron spectroscopy. Wear 261, 1155–1162 (2006)

Sung, I.H., Yang, J.C., Kim, D.E., Shin, B.S.: Micro/nano-tribological characteristics of self-assembled monolayer and its application in nano-structure fabrication. Wear 255, 808–818 (2003)

Sung, I.H., Lee, H.S., Kim, D.E.: Effect of surface topography on the frictional behavior at the micro/nano-scale. Wear 254, 1019–1031 (2003)

Zalnezhad, E., Sarhan, A.A.D.M., Hamd, M.: Surface hardness prediction of CrN thin film coating on AL7075-T6 alloy using fuzzy logic system. Int. J. Precis Eng. Manuf. 14, 467–473 (2013)

Singh, R.A., Pham, D.C., Kim, J., Yang, S., Yoon, E.S.: Bio-inspired dual surface modification to improve tribological properties at small-scale. Appl. Surf. Sci. 255, 4821–4828 (2009)

Satyanarayana, N., Lau, K.H., Sinha, S.K.: Nanolubrication of poly (methyl methacrylate) films on Si for microelectromechanical systems applications. Appl. Phys. Lett. 93, 261906 (2008)

Singh, R.A., Siyuan, L., Satyanarayana, N., Kustandi, T.S., Sinha, S.K.: Bio-inspired polymeric patterns with enhanced wear durability for microsystem applications. Mater. Sci. Eng. C 31, 1577–1583 (2011)

Singh, R.A., Satyanarayana, N., Kustandi, T.S., Sinha, S.K.: Tribo-functionalizing Si and SU8 materials by surface modification for application in MEMS/NEMS actuator-based devices. J. Phys. D Appl. Phys. 44, 015301 (2011)

Jiguet, S., Judelewicz, M., Mischler, S., Hofmann, H., Bertsch, A., Renaud, P.: SU-8 nanocomposite coatings with improved tribological performance for MEMS. Surf. Coat. Technol. 201, 2289–2295 (2006)

Tay, N.B., Minn, M., Sinha, S.K.: Polymer jet printing of SU-8 micro-dot patterns on Si surface: optimization of tribological properties. Tribol. Lett. 42, 215–222 (2011)

Zhou, L., Kato, K., Umehara, N., Miyake, Y.: The effects of texture height and thickness of amorphous carbon nitride coating of a hard disk slider on the friction and wear of the slider against a disk. Tribol. Int. 33, 665–672 (2000)

Porta, M., Fantoni, G., Lambert, P.: An integrated and compact device for microassembly exploiting electrostatic sorting and capillary grasping. CIRP J. Manuf. Sci. Technol. 3, 185–190 (2010)

Ghodssi, R., Denton, D.D., Seireg, A.A., Howland, B.: Rolling friction in a linear microactuator. J. Vac. Sci. Technol., A 11, 803–807 (1993)

Lin, T.W., Modafe, A., Shapiro, B., Ghodssi, R.: Characterization of dynamic friction in MEMS-based microball bearings. IEEE Trans. Instrum. Meas. 53, 839–846 (2004)

Modafe, A., Ghalichechian, N., Frey, A., Lang, J.H., Ghodssi, R.: Microball-bearing-supported electrostatic micromachines with polymer dielectric films for electromechanical power conversion. J. Micromech. Microeng. 16, S182–S190 (2006)

Ghalichechian, N., Modafe, A., Lang, J.H., Ghodssi, R.: Dynamic characterization of a linear electrostatic micromotor supported on microball bearings. Sensor. Actuat. A Phys. 136, 496–503 (2007)

Ghalichechian, N., Modafe, A., Beyaz, M.I., Ghodssi, R.: Design, fabrication, and characterization of a rotary micromotor supported on microball bearings. J. Microelectromech. Syst. 17, 632–642 (2008)

Waits, C.M., Geil, B., Ghodssi, R.: Encapsulated ball bearings for rotary micro machines. J. Micromech. Microeng. 17, S224–S229 (2007)

McCarthy, M., Waits, C.M., Ghodssi, R.: Dynamic friction and wear in a planar-contact encapsulated microball bearing using an integrated microturbine. J. Microelectromech. Syst. 18, 263–273 (2009)

Tan, X., Modafe, A., Ghodssi, R.: Measurement and modeling of dynamic rolling friction in linear microball bearings. J. Dyn. Syst. Meas. Control. 128, 891–898 (2006)

Waits, C.M., McCarthy, M., Ghodssi, R.: A microfabricated spiral-groove turbopump supported on microball bearings. J. Microelectromech. Syst. 19, 99–109 (2010)

Olaru, D.N., Stamate, C., Dumitrascu, A., Prisacaru, G.: New micro tribometer for rolling friction. Wear 271, 842–852 (2011)

Sinha, S.K., Pang, R., Tang, X.: Application of micro-ball bearing on Si for high rolling life-cycle. Tribol. Int. 43, 178–187 (2010)

Chun, B.S., Suto, H.: The relationship between hardness and wear of alloys in liquid nitrogen. Trans. ISIJ 23, 425–433 (1983)

Nishimura, A., Yamamoto, J., Nyilas, A.: Fatigue crack growth rate of SUS 316 and weld joint with natural crack at 7 K. Adv. Cryog. Eng. Mater. 44, 81–88 (1998)

Hanrahan, B., Misra, S., Beyaz, M., Feldman, J., Waits, M., Ghodssi, R.: An adhesion-dominated rolling friction regime unique to micro-scale ball bearings. Tribol. Lett. 56, 215–222 (2014)

Hanrahan, B., Misra, S., Waits, C.M., Ghodssi, R.: Wear mechanisms in microfabricated ball bearing systems. Wear 326–327, 1–9 (2015)

Hanrahan, B., Waits, C.M., Ghodssi, R.: Isotropic etching technique for three-dimensional microball bearing raceways. J. Micromech. Microeng. 24, 1–13 (2014)

Al-Bayati, A.H., Orrman-Rossiter, K.G., Van den Berg, J.A., Armour, D.G.: Composition and structure of the native Si oxide by high depth resolution medium energy ion scattering. Surf. Sci. 241, 91–102 (1991)

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP; No. 2010-0018289).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oh, DS., Kim, HJ., Kim, JK. et al. Friction and Deformation Behaviors of ~60-μm Stainless Steel Micro-balls for Application in Small Precision Devices. Tribol Lett 59, 47 (2015). https://doi.org/10.1007/s11249-015-0573-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0573-7