Abstract

The polyaryletherketone (PAEK) family of thermoplastics is increasingly used in engineering applications that require outstanding tribological properties. Considerable attention has thus been paid to their wear behavior in a number of environments. However, little focus has been given to PAEK response to fretting conditions. Fretting wear results from the repeated slip of mutually loaded contacts. In this study, a custom built multi-axis tribometer has been shown to replicate fretting of PAEK in a pin-on-flat configuration. The experimentation and analysis has provided new insights into this phenomenon.

Similar content being viewed by others

References

Waterhouse, R.B.: Fretting fatigue. Applied science, London (1981)

Mutoh, Y., Kinyon, S.E., Hoeppner, D.W. (eds.): Fretting Fatigue: Advances in Basic Understanding and Applications, STP 1425. ASTM International, West Conshohocken, PA (2003)

Hills, D.A.: Mechanics of fretting fatigue. Wear 175(1), 107–113 (1994)

Play, D.: Mutual overlap coefficient and wear debris motion in dry oscillating friction and wear tests. ASLE Trans. 28(4), 527–535 (1985)

Feeny, B., et al.: A historical review on dry friction and stick–slip phenomena. Appl. Mech. Rev. 51(5), 321–341 (1998)

Etsion, I.: Revisiting the Cattaneo–Mindlin concept of interfacial slip in tangentially loaded compliant bodies. J. Tribol. 132(2), 020801 (2010)

Hoeppner, D., Adibnazari, S., Moesser, M.W.: Literature Review and Preliminary Studies of Fretting and Fretting Fatigue Including Special Applications to Aircraft Joints. Department of Mechanical Engineering, Utah University, Salt Lake City, UT (1994)

Gordelier, S.C., Chivers, T.C.: A literature review of palliatives for fretting fatigue. Wear 56(1), 177–190 (1979)

Kang, C., Eiss Jr, N.S.: Fretting wear of polysiloxane–polyimide copolymer coatings as a function of varying humidity. Wear 158(1–2), 29–40 (1992)

Higham, P.A., Stott, F.H., Bethune, B.: Mechanisms of wear of the metal surface during fretting corrosion of steel on polymers. Corros. Sci. 18(1), 3–13 (1978)

Gaydos, P.: Fretting wear of polymeric coatings. Wear Mater. 2, 529–535 (1989)

Zhou, Z.R., Vincent, L.: Lubrication by thin polystyrene coating in fretting. Wear 231(2), 179–184 (1999)

Kang, C., Eiss, N.S.: Fretting of polyimide coatings part I: structure and moisture effects. Wear 181, 94–100 (1995)

Dahmani, N., et al.: Velocity accommodation in polymer fretting. Wear 158(1–2), 15–28 (1992)

Rabbe, L.M., et al.: Fretting deterioration of orthopaedic implant materials: search for solutions. Clin. Mater. 15(4), 221–226 (1994)

Briscoe, B.J., et al.: Contact damage of poly(methylmethacrylate) during complex microdisplacements. Wear 240(1–2), 27–39 (2000)

Chateauminois, A., Kharrat, M., Krichen, A.: Analysis of fretting damage in polymers by means of fretting maps. ASTM Spec. Tech. Publ. 1367, 352–368 (2000)

Briscoe, B.J., et al.: Fretting wear behaviour of polymethylmethacrylate under linear motions and torsional contact conditions. Tribol. Int. 31(11), 701–711 (1998)

Briscoe, B.J., Chateauminois, A.: Measurements of friction-induced surface strains in a steel/polymer contact. Tribol. Int. 35(4), 245–254 (2002)

Briscoe, B.J., et al.: Acoustic noise emission in a model PMMA/steel fretting contact. Tribol. Ser. 39, 673–681 (2001)

Chateauminois, A., Briscoe, B.J.: Nano-rheological properties of polymeric third bodies generated within fretting contacts. Surf. Coat. Technol. 163–164, 435–443 (2003)

Higham, P.A., Bethune, B., Stott, F.H.: Changes in the surface morphology of polycarbonate induced by fretting. J. Mater. Sci. 12(12), 2503–2510 (1977)

Terekhina, S., Salvia, M., Fouvry, S.: Contact fatigue and wear behaviour of bismaleimide polymer subjected to fretting loading under various temperature conditions. Tribol. Int. 44(4), 396–408 (2011)

Krichen, A., et al.: Surface damage of poly(methylmethacrylate) under fretting loading. Wear 230(2), 146–155 (1999)

Guo, Q., Luo, W.: Mechanisms of fretting wear resistance in terms of material structures for unfilled engineering polymers. Wear 249(10–11), 924–931 (2001)

Pan, G., et al.: Fretting wear behaviors of nanometer Al2O3 and SiO2 reinforced PEEK composites. Wear 266(11–12), 1208–1215 (2009)

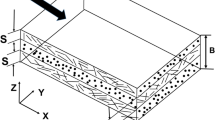

Laux, K.A., Schwartz, C.J.: Influence of linear reciprocating and multi-directional sliding on PEEK wear performance and transfer film formation. Wear 301(1–2), 727–734 (2013)

Blundell, D.J., Osborn, B.N.: The morphology of poly(aryl-ether-ether-ketone). Polymer 24(8), 953–958 (1983)

ASTM Subcommittee D20. 10 on Mechanical Properties: Standard test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing Materials (1997)

Omar, M.K., Atkins, A.G., Lancaster, J.K.: The role of crack resistance parameters in polymer wear. J. Phys. D Appl. Phys. 19(2), 177 (1986)

Laux, K.A., Schwartz, C.J.: Effects of contact pressure, molecular weight, and supplier on the wear behavior and transfer film of polyetheretherketone (PEEK). Wear 297(1–2), 919–925 (2013)

Briscoe, B.J., Stolarski, T.A.: Combined rotating and linear motion effects on the wear of polymers. Nature 281(5728), 206–208 (1979)

Briscoe, B.J., Stolarski, T.A.: Transfer wear of polymers during combined linear motion and load axis spin. Wear 104(2), 121–137 (1985)

Wang, A.: A unified theory of wear for ultra-high molecular weight polyethylene in multi-directional sliding. Wear 248(1–2), 38–47 (2001)

Lu, Z.P., Friedrich, K.: On sliding friction and wear of PEEK and its composites. Wear 181, 624–631 (1995)

Stachowiak, G., Batchelor, A.W.: Engineering Tribology. Butterworth-Heinemann, London (2013)

Baumberger, T., Caroli, C.: Solid friction from stick–slip down to pinning and aging. Adv. Phys. 55(3–4), 279–348 (2006)

Zhang, M.Q., Lu, Z.P., Friedrich, K.: Thermal analysis of the wear debris of polyetheretherketone. Tribol. Int. 30(2), 103–111 (1997)

Xia, Z.Y., Sue, H.J., Rieker, T.P.: Morphological evolution of poly(ethylene terephthalate) during equal channel angular extrusion process. Macromolecules 33(23), 8746–8755 (2000)

Hay, J.N., Langford, J.I., Lloyd, J.R.: Variation in unit cell parameters of aromatic polymers with crystallization temperature. Polymer 30(3), 489–493 (1989)

Marcellan, A., et al.: Third body effects in the wear of polyamide: micro-mechanisms and wear particles analysis. Wear 266(9), 1013–1020 (2009)

Li, T.Q., et al.: Friction induced mechanochemical and mechanophysical changes in high performance semicrystalline polymer. Polymer 40(16), 4451–4458 (1999)

Chu, J.-N., Schultz, J.: The influence of microstructure on the failure behaviour of PEEK. J. Mater. Sci. 25(8), 3746–3752 (1990)

Saib, K.S., Evans, W.J., Isaac, D.H.: The role of microstructure during fatigue crack growth in poly(aryl ether ether ketone) (PEEK). Polymer 34(15), 3198–3203 (1993)

Zhang, G., et al.: Temperature dependence of the tribological mechanisms of amorphous PEEK (polyetheretherketone) under dry sliding conditions. Acta Mater. 56(10), 2182–2190 (2008)

Acknowledgments

The authors would like to thank the members of the consortium for Advancing Performance Polymers for Energy AppLications (APPEAL) at Texas A&M University for providing the financial support and PEEK materials used in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Laux, K.A., Sue, H.J., Montoya, A. et al. Wear Behavior of Polyaryletherketones Under Multi-directional Sliding and Fretting Conditions. Tribol Lett 58, 41 (2015). https://doi.org/10.1007/s11249-015-0517-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0517-2