Abstract

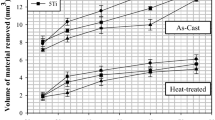

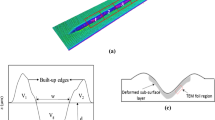

This paper focuses on the tribological characterization of new martensitic stainless steels by two different tribological methods (scratch and dry wear tests) and their comparison to the austenitic standard stainless steel AISI 316L. The scratch test allows obtaining critical loads, scratch friction coefficients, scratch hardness and specific scratch wear rate, and the dry wear test to quantify wear volumes. The damage has been studied by ex situ scanning electron microscopy. Wear resistance was related to the hardness and the microstructure of the studied materials, where martensitic stainless steels exhibit higher scratch wear resistance than the austenitic one, but higher hardness of the martensitic alloys did not give better scratch resistance when comparing with themselves. It has been proved it is possible to evaluate the scratch wear resistance of bulk stainless steels using scratch test. The austenitic material presented lower wear volume than the martensitic ones after the dry wear test due to phase transformation and the hardening during sliding.

Similar content being viewed by others

References

Kwok, C.T., Lo, K.H., Cheng, F.T., Man, H.C.: Effect of processing conditions on the corrosion performance of laser surface-melted AISI 440C martensitic stainless steel. Surf. Coat. Technol. 166, 221–230 (2003)

Cheng, Z., Li, C.X., Dong, H., Bell, T.: Low temperature plasma nitrocarburising of AISI 316 austenitic stainless steel. Surf. Coat. Technol. 191, 195–200 (2005)

Ma, X.P., Wang, L.J., Liu, C.M., Subramanian, S.V.: Microstructure and properties of 13Cr5Ni1Mo0.025Nb0.09V0.06 N super martensitic stainless steel. Mater. Sci. Eng., A 539, 271–279 (2012)

Thibault, D., Bocher, P., Thomas, M.: Residual stress and microstructure in welds of 13%Cr–4%Ni martensitic stainless steel. J. Mater. Process. Technol. 209, 2195–2202 (2009)

Li, C.X., Bell, T.: Corrosion properties of plasma nitrided AISI 410 martensitic stainless steel in 3.5 % NaCl and 1 % HCl aqueous solutions. Corros. Sci. 48, 2036–2049 (2006)

Puli, R., Janaki Ram, G.D.: Microstructures and properties of friction surfaced coatings in AISI 440C martensitic stainless steel. Surf. Coat. Technol 207, 310–318 (2012)

Garcideandrés, C., Caruana, G., Alvarez, L.F.: Control of M23C6 carbides in 0.45C–13Cr martensitic stainless steel by means of three representative heat treatment parameters. Mater. Sci. Eng., A 241, 211–215 (1998)

Mahmoudi, A., Ghavidel, M.R.Z., Nedjad, S.H., Heidarzadeh, A., Ahmadabadi, M.N.: Aging behavior and mechanical properties of maraging steels in the presence of submicrocrystalline Laves phase particles. Mater. Charact. 62, 976–981 (2011)

Meshram, S.D., Madhusudhan Reddy, G., Pandey, S.: Friction stir welding of maraging steel (Grade-250). Mater. Des. 49, 58–64 (2013)

Jiang, H., Browning, R., Sue, H.-J.: Understanding of scratch-induced damage mechanisms in polymers. Polymer (Guildf). 50, 4056–4065 (2009)

Bull, S.J., Berasetegui, E.G.: An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol. Int. 39, 99–114 (2006)

Rodrigo, A., Ichimura, H.: Analytical correlation of hardness and scratch adhesion for hard films. Surf. Coat. Technol. 148, 8–17 (2001)

Rudermann, Y., Iost, A., Bigerelle, M.: Scratch tests to contribute designing performance maps of multilayer polymeric coatings. Tribol. Int. 44, 585–591 (2011)

Browning, R., Sue, H.-J., Minkwitz, R., Charoensirisomboon, P.: Effects of acrylonitrile content and molecular weight on the scratch behavior of styrene-acrylonitrile random copolymers. Polym. Eng. Sci. 51, 2282–2294 (2011)

Petit, F., Ott, C., Cambier, F.: Multiple scratch tests and surface-related fatigue properties of monolithic ceramics and soda lime glass. J. Eur. Ceram. Soc. 29, 1299–1307 (2009)

Friedrich, K., Sue, H.J., Liu, P., Almajid, A.A.: Scratch resistance of high performance polymers. Tribol. Int. 44, 1032–1046 (2011)

Xiang, C., Sue, H.J., Chu, J., Coleman, B.: Scratch behavior and material property relationship in polymers. J. Polym. Sci., Part B: Polym. Phys. 39, 47–59 (2001)

Choi, W.-J., Lee, J.H., Weon, J.-I.: Effects of photodegradation and thermal ageing on the scratch behavior of uncoated thermoplastic olefin. Tribol. Int. 67, 90–97 (2013)

Bull, S.J.: Failure mode maps in the thin film scratch adhesion test. Tribol. Int. 30, 491–498 (1997)

Bull, S.J.: Can scratch testing be used as a model for the abrasive wear of hard coatings? Wear 233–235, 412–423 (1999)

Sander, T., Tremmel, S., Wartzack, S.: A modified scratch test for the mechanical characterization of scratch resistance and adhesion of thin hard coatings on soft substrates. Surf. Coat. Technol. 206, 1873–1878 (2011)

Lin, J.-S., Zhou, Y.: Can scratch tests give fracture toughness? Eng. Fract. Mech. 109, 161–168 (2013)

Akono, A.-T., Ulm, F.-J.: Scratch test model for the determination of fracture toughness. Eng. Fract. Mech. 78, 334–342 (2011)

Beake, B.D., Liskiewicz, T.W.: Comparison of nano-fretting and nano-scratch tests on biomedical materials. Tribol. Int. 63, 123–131 (2013)

ASTM International, ASTM C1624–05. Standard test method for adhesion making potentiostatic and potentiodynamic anodic polarization measurements, 2010: ASTM International, ASTM C1624–05. Standard test method for adhesion making potentiostatic and potentiodynamic anodic polarization measurements, 2010

Kurkcu, P., Andena, L., Pavan, A.: An experimental investigation of the scratch behaviour of polymers: 1. Influence of rate-dependent bulk mechanical properties. Wear 290–291, 86–93 (2012)

Francois, R.: Métallurgie et traitement thermique de nouveaux aciers maraging. Trait. Therm. 390, 51–56 (2008)

Samuels, L.E.: Light Microscopy of Carbon Steels. Materials Park, Ohio: ASM International, c1999. (199)AD

Tsakiris, V., Edmonds, D.V.: Martensite and deformation twinning in austenitic steels. Mater. Sci. Eng., A 273–275, 430–436 (1999)

Tong, Z., Ding, C., Yan, D.: A fracture model for wear mechanism in plasma sprayed ceramic coating materials. Wear 155, 309–316 (1992)

Vargonen, M., Yang, Y., Huang, L., Shi, Y.: Molecular simulation of tip wear in a single asperity sliding contact. Wear 307, 150–154 (2013)

Farias, M.C.M., Souza, R.M., Sinatora, A., Tanaka, D.K.: The influence of applied load, sliding velocity and martensitic transformation on the unlubricated sliding wear of austenitic stainless steels. Wear 263, 773–781 (2007)

Zandrahimi, M., Bateni, M.R., Poladi, A., Szpunar, J.A.: The formation of martensite during wear of AISI 304 stainless steel. Wear 263, 674–678 (2007)

Misra, R.D.K., Venkatsurya, P., Wu, K.M., Karjalainen, L.P.: Ultrahigh strength martensite–austenite dual-phase steels with ultrafine structure: the response to indentation experiments. Mater. Sci. Eng., A 560, 693–699 (2013)

Song, E.P., Hwang, B., Lee, S., Kim, N.J., Ahn, J.: Correlation of microstructure with hardness and wear resistance of stainless steel blend coatings fabricated by atmospheric plasma spraying. Mater. Sci. Eng., A 429, 189–195 (2006)

Acknowledgments

The authors would like to thank to BPI, Region Centre and Tours Plus for support of this research, and also to Aubert and Duval and UF1 for providing the materials of this study. This work is done under the project FUI 11 Mekinox. We also wish to appreciate the helpful advice from Aubert and Duval.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dalmau, A., Rmili, W., Joly, D. et al. Tribological Behavior of New Martensitic Stainless Steels Using Scratch and Dry Wear Test. Tribol Lett 56, 517–529 (2014). https://doi.org/10.1007/s11249-014-0429-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-014-0429-6