Abstract

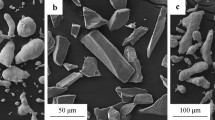

(TiB2–TiC)–Ni/TiAl/Ti functionally gradient materials were prepared by field-activated pressure-assisted synthesis processes. (TiB2–TiC)–Ni composite ceramic, the top layer of the functional gradient materials, was prepared in situ by the combustion synthesis process using Ti and B4C powders as raw materials. Scanning electron microscope (SEM) images of the ceramic layer revealed that the TiB2 and TiC particles in the composite were fine and homogeneously dispersed in the Ni matrix. The friction and wear properties of the (TiB2–TiC)–Ni ceramic were evaluated by sliding against a GCr15 disk at temperatures from ambient up to 400 °C. The experimental results showed that the friction coefficient of the (TiB2–TiC)–Ni ceramic decreased with the increasing testing temperature, load, and sliding speed. However, the loss rate decreased at higher temperature and increased at higher load and higher sliding speed. The wear mechanisms of (TiB2–TiC)–Ni ceramic mainly depend upon thermal oxidation at higher temperature, load, and sliding speed. The worn topography and phase component of the worn surfaces were analyzed using SEM, energy dispersive spectroscopy, and X-ray diffraction. The oxide films of Fe2O3, TiO2, and B2O3 formed during the friction process play an important role in lubrication, which results in a smaller friction coefficient.

Similar content being viewed by others

References

Rebelo de Figueiredo, M., Muratore, C., Franz, R., Chromik, R.R., Wahl, K.J., Voevodin, A.A., O’Sullivan, M., Lechthaler, M., Mitterer, C.: In situ studies of TiC11−x N x hard coating tribology. Tribol. Lett. 40, 365–373 (2010)

Shaha, K.P., Pei, Y.T., Martinez-Martinez, D., De Hosson, J.Th.M.: Influence of surface roughness on the transfer film formation and frictional behavior of TiC/a–C nanocomposite coatings. Tribol. Lett. 41, 97–101 (2011)

Du, B., Wang, X., Zou, Z.: Microstructure and tribological behavior of laser in situ synthesized TiC-reinforced Fe-based composite coatings. Tribol. Lett. 43, 295–301 (2011)

Kumar, S., Chakraborty, M., Subramanya Sarma, V., Murty, B.S.: Tensile and wear behaviour of in situ Al–7Si/TiB2 particulate composites. Wear 265, 134–142 (2008)

Kumar, S., Subramanya Sarma, V., Murty, B.S.: High temperature wear behavior of Al–4Cu–TiB2 in situ composites. Wear 268, 1266–1274 (2010)

Wang, X.H., Zhang, M., Du, B.S.: Fabrication in situ TiB2–TiC–Al2O3 multiple ceramic particles reinforced Fe-based composite coatings by gas tungsten arc welding. Tribol. Lett. 41, 171–176 (2011)

Akhtar, F.: Microstructure evolution and wear properties of in situ synthesized TiB and TiC reinforced steel matrix composites. J. Alloys Compd. 459, 491–497 (2008)

Zhang, X., Yang, J., Ma, J., Hao, J., Bi, Q., Liang, Y., Liu, W.: The tribological behaviour of Fe–28Al–5Cr/TiC under liquid paraffine lubrication. Tribol. Lett. 45, 109–116 (2012)

Sun, G.J., Wu, S.J., Su, G.C.: Research on impact wear resistance of in situ reaction TiCp/Fe composite. Wear 269, 285–290 (2010)

Vallauri, D., Atias Adrian, I.C., Chrysanthou, A.: TiC–TiB2 composites: a review of phase relationships, processing and properties. J. Eur. Ceram. Soc. 28, 1697–1713 (2008)

Zou, B., Shen, P., Gao, Z., Jiang, Q.: Combustion synthesis of TiC x –TiB2 composites with hypoeutectic, eutectic and hypereutectic microstructures. J. Eur. Ceram. Soc. 28, 2275–2279 (2008)

Zhao, H., Cheng, Y.B.: Formation of TiB2–TiC composites by reactive sintering. Ceram. Int. 25, 353–358 (1999)

Zhao, Z., Zhang, L., Song, Y., Wang, W., Liu, H.: Microstructures and properties of large bulk solidified TiC–TiB2 composites prepared by combustion synthesis under high gravity. Scripta Mater. 61, 281–284 (2009)

Wang, Z.T., Zhou, X.H., Zhao, G.G.: Microstructure and formation mechanism of in situ TiC–TiB2/Fe composite coating. Trans. Nonferr. Met. Soc. China 18, 831–835 (2008)

Li, B., Liu, Y., Li, J., Cao, H., He, L.: Effect of sintering process on the microstructures and properties of in situ TiB2–TiC reinforced steel matrix composites produced by spark plasma sintering. J. Mater. Process. Technol. 210, 91–95 (2010)

Xu, C.L., Wang, H.Y., Yang, Y.F., Jiang, Q.C.: Effect of Al–P–Ti–TiC–Nd2O3 modifier on the micro-structure and mechanical properties of hypereutectic Al-20 wt% Si alloy. Mater. Sci. Eng. A 452, 341–346 (2007)

Chen, S.P., Meng, Q.S., Zhao, J.F., Munir, Z.A.: Synthesis and characterization of TiB2–Ni–Ni3Al–CrNi alloy graded material by field-activated combustion. J. Alloys Compd. 476, 889–893 (2009)

Chen, S.P., Meng, Q.S., Liu, W., Munir, Z.A.: Titanium diboride–nickel graded materials prepared by field-activated, pressure-assisted synthesis process. J. Mater. Sci. 44, 1121–1126 (2009)

He, L., Zhang, X., Tong, C.: Surface modification of pure titanium treated with B4C at high temperature. Surf. Coat. Technol. 200, 3016–3020 (2006)

Oh, D.Y., Kim, H.C., Yoon, J.K., Shon, I.J.: Simultaneous synthesis and consolidation process of ultra-fine WSi2–SiC and its mechanical properties. J. Alloys Compd. 386, 270–275 (2005)

Yang, Z.L., Ouyang, J.H., Liu, Z.G., Liang, X.S.: Wear mechanisms of TiN–TiB2 ceramic in sliding against alumina from room temperature to 700 °C. Ceram. Int. 36, 2129–2135 (2010)

Jianxin, D., Wenlong, S., Hui, Z., Pei, Y., Aihua, L.: Friction and wear behaviors of the carbide tools embedded with solid lubricants in sliding wear tests and in dry cutting processes. Wear 270, 666–674 (2011)

Li, Y., Zou, Z., Feng, T., Wang, X.: Oxidation resistance and phase constituents in the brazing interface of WC–TiC–Co hard alloys. J. Mater. Process. Technol. 122, 51–55 (2002)

Liu, N., Xu, Y.D., Li, H., Chen, M.H., Zhou, J., Xie, F., Yang, H.D.: Cutting and wearing characteristics of TiC-based cermets cutters with nano-TiN addition. J. Mater. Process. Technol. 161, 478–484 (2005)

Jianxin, D., Hui, Z., Ze, W., Yunsong, L., Youqiang, X., Shipeng, L.: Unlubricated friction and wear behaviors of Al2O3/TiC ceramic cutting tool materials from high temperature tribological tests. Int. J. Refract. Met. Hard Mater. 35, 17–26 (2012)

Jerome, S., Ravisankar, B., Mahato, P.K., Natarajan, S.: Synthesis and evaluation of mechanical and high temperature tribological properties of in situ Al–TiC composites. Tribol. Int. 43, 2029–2036 (2010)

Guo, C., Zhou, J., Zhao, J., Wang, L., Youjun, Y., Chen, J., Zhou, H.: Microstructure and tribological properties of a HfB2-containing Ni-based composite coating produced on a pure Ti substrate by laser cladding. Tribol. Lett. 44, 187–200 (2011)

Acknowledgments

This study was supported by projects of the National Science Foundation of China (No. 50975190), Shanxi Province Science Foundation for Youth and Young Scientists Fund of the National Natural Science Foundation of China (51101111).

Conflict of interest

None.

Ethical Standards

The study has been performed in accordance with the ethical standards laid down in the 1964 Declaration of Helsinki. All the authors agree to submit the paper to Tribology Letters.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, L., Chen, S., Xue, P. et al. Wear Behavior of (TiB2–TiC)–Ni/TiAl/Ti Gradient Materials Prepared by the FAPAS Process. Tribol Lett 49, 313–322 (2013). https://doi.org/10.1007/s11249-012-0070-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-012-0070-1