Abstract

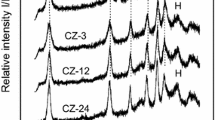

The application of different methods for a microstructural analysis of functional catalysts is reported for the example of different Cu/ZnO-based methanol synthesis catalysts. Transmission electron microscopy and diffraction were used as complementary techniques to extract information on the size and the defect concentration of the Cu nano-crystallites. The results, strengths and limitations of the two techniques and of different evaluation methods for line profile analysis of diffraction data including Rietveld-refinement, Scherrer- and (modified) Williamson–Hall-analyses, single peak deconvolution and whole powder pattern modeling are compared and critically discussed. It was found that in comparison with a macrocrystalline pure Cu sample, the catalysts were not only characterized by a smaller crystallite size, but also by a high concentration of lattice defects, in particular stacking faults. Neutron diffraction was introduced as a valuable tool for such analysis, because of the larger number of higher-order diffraction peaks that can be detected with this method. An attempt is reported to quantify the different types of defects for a selected catalyst.

Similar content being viewed by others

References

Dahl S, Logadottir A, Egeberg RC, Larsen JH, Chorkendorff I, Tornqvist E, Norskov JK (1999) Role of steps in N-2 activation on Ru(0001). Phys Rev Lett 83(9):1814–1817. doi:10.1103/PhysRevLett.83.1814

Rostrup-Nielsen J, Norskov JK (2006) Step sites in syngas catalysis. Top Catal 40(1–4):45–48. doi:10.1007/s11244-006-0107-5

Abild-Pedersen F, Greeley J, Norskov JK (2005) Understanding the effect of steps, strain, poisons, and alloying: methane activation on Ni surfaces. Catal Lett 105(1–2):9–13. doi:10.1007/s10562-005-7998-9

Jiang T, Mowbray DJ, Dobrin S, Falsig H, Hvolbaek B, Bligaard T, Norskov JK (2009) Trends in CO oxidation rates for metal nanoparticles and close-packed, stepped, and kinked surfaces. J Phys Chem C 113(24):10548–10553. doi:10.1021/Jp811185g

Freund HJ (2010) Model studies in heterogeneous catalysis. Chem Eur J 16(31):9384–9397. doi:10.1002/chem.201001724

Datye AK (2003) Electron microscopy of catalysts: recent achievements and future prospects. J Catal 216(1–2):144–154. doi:10.1016/S0021-9517(02)00113-6

Weidenthaler C (2011) Pitfalls in the characterization of nanoporous and nanosized materials. Nanoscale 3(3):792–810. doi:10.1039/C0nr00561d

Pandey AD, Guttel R, Leoni M, Schuth F, Weidenthaler C (2010) Influence of the microstructure of gold-zirconia yolk–shell catalysts on the CO oxidation activity. J Phys Chem C 114(45):19386–19394. doi:10.1021/Jp106436h

Vogel W (1990) Size distributions of supported metal-catalysts—an analytical X-ray-line profile fitting routine. J Catal 121(2):356–363. doi:10.1016/0021-9517(90)90244-E

Tsybulya SV, Kryukova GN, Goncharova SN, Shmakov AN, Balzhinimaev BS (1995) Study of the real structure of silver supported catalysts of different dispersity. J Catal 154(2):194–200. doi:10.1006/jcat.1995.1160

Bautista FM, Campelo JM, Garcia A, Luna D, Marinas JM, Quiros RA, Romero AA (1998) Influence of surface support properties on the liquid-phase selective hydrogenation of phenylacetylene on supported nickel catalysts. Catal Lett 52(3–4):205–213. doi:10.1023/A:1019008528391

Mittemeijer EJ, Scardi P (2004) Diffraction analysis of the microstructure of materials. Springer, Berlin

Mittemeijer EJ, Welzel U (2008) The state of the art of the diffraction analysis of crystallite size and lattice strain. Z Kristallogr 223:552–560

Savaloni H, Gholipour-Shahraki M, Player MA (2006) A comparison of different methods for X-ray diffraction line broadening analysis of Ti and Ag UHV deposited thin films: nanostructural dependence on substrate temperature and film thickness. J Phys D Appl Phys 39(10):2231

Behrens M, Schlögl R (2012) X-ray diffraction and small angle X-ray scattering. In: Characterization of solid materials and heterogeneous catalysts, Wiley, p 609–653. doi:10.1002/9783527645329.ch15

Kasatkin I, Kurr P, Kniep B, Trunschke A, Schlogl R (2007) Role of lattice strain and defects in copper particles on the activity of Cu/ZnO/Al2O3 catalysts for methanol synthesis. Angew Chem Int Ed 46(38):7324–7327. doi:10.1002/anie.200702600

Gunter MM, Ressler T, Bems B, Buscher C, Genger T, Hinrichsen O, Muhler M, Schlögl R (2001) Implication of the microstructure of binary Cu/ZnO catalysts for their catalytic activity in methanol synthesis. Catal Lett 71(1–2):37–44

Behrens M, Studt F, Kasatkin I, Kühl S, Hävecker M, Abild-Pedersen F, Zander S, Girgsdies F, Kurr P, Kniep B-L, Tovar M, Fischer RW, Norskov JK, Schlögl R (2012) The active site of methanol synthesis over Cu/ZnO/Al2O3 industrial catalysts. Science 336(6083):893–897

Behrens M (2009) Meso- and nano-structuring of industrial Cu/ZnO/(Al2O3) catalysts. J Catal 267(1):24–29. doi:10.1016/j.jcat.2009.07.009

Waller D, Stirling D, Stone FS, Spencer MS (1989) Copper-zinc oxide catalysts. Activity in relation to precursor structure and morphology. Faraday Discuss Chem Soc 87:107–120

Spencer MS (1999) The role of zinc oxide in Cu/ZnO catalysts for methanol synthesis and the water-gas shift reaction. Top Catal 8:259–266

Behrens M, Furche A, Kasatkin I, Trunschke A, Busser W, Muhler M, Kniep B, Fischer R, Schlogl R (2010) The potential of microstructural optimization in metal/oxide catalysts: higher intrinsic activity of copper by partial embedding of copper nanoparticles. ChemCatChem 2(7):816–818. doi:10.1002/cctc.201000017

Klug HP, Alexander LE (1974) X-ray diffraction procedures. Wiley, New York

Balzar D, Audebrand N, Daymond MR, Fitch A, Hewat A, Langford JI, Le Bail A, Louër D, Masson O, McCowan CN, Popa NC, Stephens PW, Toby BH (2004) Size–strain line-broadening analysis of the ceria round-robin sample. J Appl Crystallogr 37(6):911–924

Többens DM, Tovar M (2002) Peak shape at the axially focusing E9 powder diffractometer—theoretical and experimental description. Appl Phys A Mater Sci Process 74:s136–s138

Caglioti G, Paoletti A, Ricci FP (1958) Choice of collimators for a crystal spectrometer for neutron diffraction. Nucl Instrum 3(4):223–228

Rietveld HM (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2(2):65–71

Wertheim GK, Butler MA, West KW, Buchanan DNE (1974) Determination of the Gaussian and Lorentzian content of experimental line shapes. Rev Sci Instrum 45(11):1369–1371

Cheary RW, Coelho AA, Cline JP (2004) Fundamental parameters line profile fitting in laboratory diffractometers. J Res Natl Inst Stand Technol 109:1–25

Le Bail A, Duroy H, Fourquet JL (1988) Ab initio structure determination of LiSbWO$_6$ by X-ray powder diffraction. Mater Res Bull 23(3):447–452

Treacy MMJ, Newsam JM, Deem MW (1991) A general recursion method for calculating diffracted intensities from crystals containing planar faults. Proc R Soc Lond A 433(1889):499–520

Leoni M, Confente T, Scardi P (2006) PM2K: a flexible program implementing whole powder pattern modelling. Z Kristallogr Suppl 23:249–254

Twigg MV, Spencer MS (2003) Deactivation of copper metal catalysts for methanol decomposition, methanol steam reforming and methanol synthesis. Top Catal 22(3–4):191–203

Romeo M, Da Costa V, Bardou F (2003) Broad distribution effects in sums of lognormal random variables. Eur Phys J B 32:513–525

Gai PL, Boyes ED (2003) Electron microscopy in heterogeneous catalysis. Institute of Physics, Bristol

Yao MH, Smith DJ, Datye AK (1993) Comparative-study of supported catalyst particles by electron-microscopy methods. Ultramicroscopy 52(3–4):282–288. doi:10.1016/0304-3991(93)90037-X

Delhez R, Keijser TH, Mittemeijer EJ (1982) Determination of crystallite size and lattice distortions through X-ray diffraction line profile analysis. Fresenius J Anal Chem 312:1–16

Warren BE (1990) X-ray diffraction. Dover, New York

Balogh L, Ribárik G, Ungár T (2006) Stacking faults and twin boundaries in fcc crystals determined by X-ray diffraction profile analysis. J Appl Phys 100:023512

Scherrer P (1918) Göttinger Nachrichten Gesell 2:98

Patterson AL (1939) The Scherrer formula for X-ray particle size determination. Phys Rev 56:978–982

Langford JI, Louër D (1996) Powder diffraction. Rep Prog Phys 59:131–234

Langford JI, Wilson AJC (1978) Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J Appl Crystallogr 11(2):102–113

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1:22–31

Brandstetter S (2008) Williamson-Hall anisotropy in nanocrystalline metals: X-ray diffraction experiments and atomistic simulations. Acta Mater 56:165–176

Ungar T, Tichy G (1999) The effect of dislocation contrast on X-ray line profiles in untextured polycrystals. Phys Stat Sol A 171:425

Warren BE (1961) X-ray measurements of stacking fault widths in fcc metals. J Appl Phys 32:2428

Ungar T, Borbely A (1996) The effect of dislocation contrast on xray line broadening: a new approach to line profile analysis. Appl Phys Lett 69:3173

Gubicza J, Szepvolgi J, Mohai I, Zsoldos L, Ungar T (2000) Particle size distribution and dislocation density determined by high resolution X-ray diffraction in nanocrystalline silicon nitride powders. Mater Sci Eng A 280:263–269

Ungar T, Gubicza J, Ribarik G, Borbely A (2001) Crystallite size distribution and dislocation structure determined by diffraction profile analysis: principles and practical applications to cubic and hexagonal crystals. J Appl Cryst 34:298–310

Snyder RL, Bunge HJ, Fiala J (2000) Defect and microstructure analysis by diffraction. OUP/International Union of Crystallography, New York

Warren BE (1959) X-ray studies of deformed metals. Prog Met Phys 8:147–202

Paterson MS (1952) X-ray diffraction by face-centered cubic crystals with deformation faults. J Appl Phys 23(8):805–811

Kandemir T (2013) In-situ study of catalytic processes at high temperatures: neutron diffraction of <p>a methanol synthesis catalyst under industrial conditions. Angew Chem Int Ed. doi:10.1002/anie.201209539

Velterop L, Delhez R, de Keijser TH, Mittemeijer EJ, Reefman D (2000) X-ray diffraction analysis of stacking and twin faults in f.c.c. metals: a revision and allowance for texture and non-uniform fault probabilities. J Appl Crystallogr 33(2):296–306

Reed RP, Schramm RE (1974) Relationship between stacking-fault energy and X-ray measurements of stacking-fault probability and microstrain. J Appl Phys 45(11):4705–4711

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kandemir, T., Kasatkin, I., Girgsdies, F. et al. Microstructural and Defect Analysis of Metal Nanoparticles in Functional Catalysts by Diffraction and Electron Microscopy: The Cu/ZnO Catalyst for Methanol Synthesis. Top Catal 57, 188–206 (2014). https://doi.org/10.1007/s11244-013-0175-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11244-013-0175-2