ABSTRACT

Purpose

To investigate the use of electrospinning for forming solid dispersions containing crystalline active pharmaceutical ingredients (API) and understand the relevant properties of the resulting materials.

Method

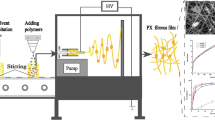

Free surface electrospinning was used to prepare nanofiber mats of poly(vinyl pyrrolidone) (PVP) and crystalline albendazole (ABZ) or famotidine (FAM) from a suspension of the drug crystals in a polymer solution. SEM and DSC were used to characterize the dispersion, XRD was used to determine the crystalline polymorph, and dissolution studies were performed to determine the influence of the preparation method on the dissolution rate.

Results

The electrospun fibers contained 31 wt% ABZ and 26 wt% FAM for the 1:2 ABZ:PVP and 1:2 FAM:PVP formulations, respectively, and both APIs retained their crystalline polymorphs throughout processing. The crystals had an average size of about 10 μm and were well-dispersed throughout the fibers, resulting in a higher dissolution rate for electrospun tablets than for powder tablets.

Conclusions

Previously used to produce amorphous formulations, electrospinning has now been demonstrated to be a viable option for producing fibers containing crystalline API. Due to the dispersion of the crystals in the polymer, tablets made from the fiber mats may also exhibit improved dissolution properties over traditional powder compression.

Similar content being viewed by others

Abbreviations

- ABZ:

-

albendazole

- API:

-

active pharmaceutical ingredient

- DSC:

-

differential scanning calorimetry

- FAM:

-

famotidine

- PVP:

-

poly(vinyl pyrrolidone)

- SEM:

-

scanning electron microscopy

- XRD:

-

X-ray diffraction

- A :

-

surface area for diffusion

- C :

-

concentration in solution

- C sat :

-

solubility

- D :

-

diffusion coefficient

- \( \frac{{dm}}{{dt}} \) :

-

dissolution rate

- g :

-

gravitational acceleration

- h :

-

diffusional path length

- ρ f :

-

density of the fluid

- ρ p :

-

density of the particle

- R :

-

radius of the particle

- μ :

-

viscosity of the fluid

- v s :

-

settling velocity

REFERENCES

Plumb K. Continuous processing in the pharmaceutical industry: Changing the mind set. Chem Eng Res Des. 2005;83(6):730–8.

Breitenbach J. Melt extrusion: from process to drug delivery technology. Eur J Pharm Biopharm. 2002;54(2):107–17.

Bell ER, Massachusetts Institute of Technology. Melt extrusion and continuous manufacturing of pharmaceutical materials [PhD Thesis]. Cambridge, MA: Massachusetts Institute of Technology; 2011.

Kim W, Massachusetts Institute of Technology. Layer bonding of solvent-cast thin films for pharmaceutical solid dosage forms [Master’s Thesis]. Cambridge, MA: Massachusetts Institute of Technology; 2010.

Brettmann BK, Bell E, Myerson AS. and Trout B L, Solid-state NMR characterization of high-loading solid solutions of API and excipients formed by electrospinning. J Pharm Sci. 2012;101(4):1538–45.

Buschle-Diller G, Cooper J, Xie Z, Wu Y, Waldrup J. Release of antibiotics from electrospun bicomponent fibers. Cellulose. 2007;14:553–62.

Yu D, Zhang X, Shen X. Brandford–White C, Zhu L. Ultrafine ibuprofen–loaded polyvinylpyrrolidone fiber mats using electrospinning. Polym Int. 2009;58:1010–3.

Verreck G, Chun I, Peeters J, Rosenblatt J, Brewster ME. Preparation and characterization of nanofibers containing amorphous drug dispersions generated by electrostatic spinning. Pharm Res. 2003;20:810–7.

Verreck G, Chun I, Rossenblatt J, Peeters J, Van Dijck A, Mensch J, Noppe M, Brewster ME. Incorporation of drugs in an amorphous state into electrospun nanofibers composed of a water-insoluble, nonbiodegradable polymer. J Control Release. 2003;92:349–60.

Ramakrishna S. An Introduction to Electrospinning and Nanofibers. Singapore: World Scientific Publishing Company; 2005.

Lukas D, Sarkar A, Pokorny P. Self-organization of jets in electrospinning from free liquid surface: a generalized approach. J Appl Phys. 2008;103(8):084309.

Yarin AL, Zussman E. Upward needleless electrospinning of multiple nanofibers. Polymer. 2004;45(9):2977–80.

Miloh T, Spivak B, Yarin AL. Needleless electrospinning: electrically driven instability and multiple jetting from the free liquid surface of a spherical liquid layer. J Appl Phys. 2009;106(11):114910.

Kostakova E, Meszaros L, Gregr J. Composite nanofibers produced by modified needleless electrospinning. Mater Lett. 2009;63(28):2419–22.

Jirsak O, Sysel P, Sanetrnik F, Hruza J, Chaloupek J. Polyamic acid nanofibers produced by needleless electrospinning. J Nanomater. 2010 Jan; ID842831.

Niu H, Lin T, Wang X. Needleless electrospinning. I. a comparison of cylinder and disk nozzles. J Appl Polym Sci. 2009;114(6):3524–30.

Wang X, Niu H, Lin T. Needleless electrospinning of nanofibers with a conical wire coil. Polym Engr Sci. 2009;49(8):1582–6.

Lu B, Wang Y, Liu Y, Duan H, Zhou J, Zhang Z, Wang Y, Li X, Wang W, Lan E. Superhigh-throughput needleless electrospinning using a rotary cone as spinneret. Small. 2010;6(15):1612–6.

Varabhas JS, Tripatanasuwan S, Chase GG, Reneker DH. Electrospun jets launched from polymeric bubbles. J Eng Fibers Fabr. 2009;4:46–50.

Forward KM, Rutledge GC. Free surface electrospinning from a wire electrode. Chem Eng J. 2012;183:492–503.

Tungprapa S, Jangchud I, Supaphol P. Release characteristics of four model drugs from drug-loaded electrospun cellulose acetate fiber mats. Polymer. 2007;48(17):5030–41.

Yu DG, Shen XX, Branford-White C, White K, Zhu LM, Bligh SWA. Oral fast-dissolving drug delivery membranes prepared from electrospun polyvinylpyrrolidone ultrafine fibers. Nanotechnology. 2009;20(5):055104.

Hancock BC, Zografi G. Characteristics and significance of the amorphous state in pharmaceutical systems. J Pharm Sci. 1997;86(1):1–12.

Chew SY, Hufnagel TC, Lim CT, Leong KW. Mechanical properties of single electrospun drug-encapsulated nanofibres. Nanotechnology. 2006;17(15):3880–91.

Natu MV, de Sousa HC, Gil MH. Effects of drug solubility, state and loading on controlled release in bicomponent electrospun fibers. Int J Pharm. 2010;397(1–2):50–8.

Ignatious F, Sun L, Lee C-P, Baldoni J. Electrospun nanofibers in oral drug delivery. Pharm Res. 2010;27(4):576–88.

Wang M, Singh H, Hatton TA, Rutledge GC. Field-responsive superparamagnetic composite nanofibers by electrospinning. Polymer. 2004;45(16):5505–14.

Tiwari MK, Yarin AL, Megaridis CM. Electrospun fibrous nanocomposites as permeable, flexible strain sensors. J Appl Phys. 2008;103(4):044305.

Salalha W, Kuhn J, Dror Y, Zussman E. Encapsulation of bacteria and viruses in electrospun nanofibers. Nanotechnology. 2006;17(18):4675–81.

Wang M, Hsieh AJ, Rutledge GC. Electrospinning of poly(MMA-co-MAA) copolymers and their layered silicate nanocomposites for improved thermal properties. Polymer. 2005;46(10):3407–18.

Wang M, Yu JH, Hsieh AJ, Rutledge GC. Effect of tethering chemistry of cationic surfactants on clay exfoliation, electrospinning and diameter of PMMA/clay nanocomposite fibers. Polymer. 2010;51(26):6295–302.

Brettmann B, Tsang S, Forward K, Rutledge G, Myerson AS, Trout BL. Free Surface Electrospinning of Microparticles. Langmuir. 2012;28(25):9714–21.

Lim J-M, Moon JH, Yi G-R, Heo C-J, Yang S-M. Fabrication of one-dimensional colloidal assemblies from electrospun nanofibers. Langmuir. 2006;22(8):3445–9.

U.S. Pharmacopeia Reference Tables. USP29-NF24. www.pharmacopeia.cn. Accessed Aug 5, 2012.

Dror Y, Salalha W, Khalfin RL, Cohen Y, Yarin AL, Zussman E. Carbon nanotubes embedded in oriented polymer nanofibers by electrospinning. Langmuir. 2003;19(17):7012–20.

Pranzo MB, Cruickshank D, Coruzzi M, Caira MR, Bettini R. Enantiotropically related albendazole polymorphs. J Pharm Sci. 2010;99(9):3731–41.

Lu J, Wang X-J, Yang X, Ching C-B. Polymorphism and Crystallization of Famotidine. Cryst Growth Des. 2007;7(9):1590–8.

Cambridge Structural Database, reference code BOGFUZ

Cambridge Structural Database, reference code FOGVIG06

Cambridge Structural Database, reference code FOGVIG07

Leuner C, Dressman J. Improving drug solubility for oral delivery using solid dispersions. Eur J Pharm Biopharm. 2000;50:47–60.

Marsac PJ, Li T, Taylor LS. Estimation of drug–polymer miscibility and solubility in amorphous solid dispersions using experimentally determined interaction parameters. Pharm Res. 2008;26(1):139–51.

ACKNOWLEDGMENTS AND DISCLOSURES

We would like to acknowledge Novartis AG for funding and support of this work. We would also like to thank Keith M. Forward for aid with free-surface electrospinning and Keith Chadwick for his input on XRD interpretation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brettmann, B.K., Cheng, K., Myerson, A.S. et al. Electrospun Formulations Containing Crystalline Active Pharmaceutical Ingredients. Pharm Res 30, 238–246 (2013). https://doi.org/10.1007/s11095-012-0868-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-012-0868-4