Abstract

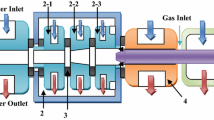

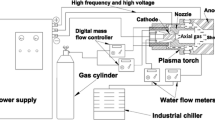

As laminar plasma jet has long stable plasma jet, low temperature gradient, negligible noise emission, good processing reproducibility and controllability, it is suitable for industrial applications with high precision requirement. However, the conventional laminar plasma torches are large in size and thus can hardly be applied in processing occasions with space limitation. In this paper, a miniature DC non-transferred arc laminar plasma torch with an external size of about 57 × 56 × 42 mm is proposed to meet the processing requirements in these occasions. It can generate long laminar plasma jet with a maximum jet length of about 300 mm at atmospheric pressure with pure nitrogen. Experimental study on the proposed plasma torch has been carried out to obtain its arc voltage characteristics and the jet length characteristics. It has been founded that the plasma torch with spiral gas flow pattern generally has higher arc voltage and longer jet length than that with axial gas flow pattern. In addition, a special jumping arc voltage characteristic and the variation appearances of the plasma jet were founded, which may be used to design miniature laminar plasma torch with high arc voltage and thus low arc current for the same output power as the conventional ones.

Similar content being viewed by others

References

Lermen RT, Machado IG (2012) Development of a new hybrid plasma torch for materials processing. J Mater Process Tech 212:2371–2379

Pfender E (1999) Where do we stand and where are we going. Plasma Chem Plasma Process 19(1):1–31

Lin HF, Liao SC, Hung SW (2005) The dc thermal plasma synthesis of ZnO nanoparticles for visible-light photocatalyst. J Photochem Photobiol A 174:82–87

Shigeta M, Murphy AB (2011) Thermal plasmas for nanofabrication. J Phys D Appl Phys 44:174025

Cao M, Gitzhofer F, Gravelle DV, Henne R, Boulos MI (1997) A torch nozzle design to improve plasma spraying techniques. Plasma Sour Sci Technol 6:39–45

Muggli FA, Molz RJ, McCullough R, Hawley D (2007) Improvement of plasma gun performance using comprehensive fluid element modeling: part I. J Therm Spray Technol 16:677–683

Samotugin SS, Pirch II, Mazur VA (2003) Optimising the design of plasma torches for surface hardening of materials. Weld Int 17(5):404–406

Li HP, Pfender E (2005) Three-dimensional effects inside a dc arc plasma torch. IEEE Trans Plasma Sci 33(2I):400–401

Das AK (2000) Arc root dynamics in high power plasma torches—evidence of chaotic behavior. Pramana 55(5–6):873–886

Duan Z, Heberlein J (2002) Arc instabilities in a plasma spray torch. J Therm Spray Technol 11:44–51

Zha BL, Jiang P, Yuan XJ, Qiao SL, Huang DY (2012) The study of plasma jet characteristics. Nucl Fusion Plasma Phys 32:187–192

Pan WX, Zhang WH, Ma W, Wu CK (2001) Characteristics of argon laminar DC plasma jet at atmospheric pressure. Plasma Chem Plasma Process 22(2):271–283

Pan WX, Zhang WH, Zhang WH, Wu CK (2001) Generation of long, laminar plasma jets at atmospheric pressure and effects of flow turbulence. Plasma Chem Plasma Process 21(1):23–35

Xiang Y, Yu DP, Cao XQ, Yao J (2014) Experimental study on characteristic of direct-curent laminar-flow nitrogen plasma-jet. High Power Laser Paticle Beams 26(09):168–172

Osaki K, Fukumasa O, Kobayashi A (2000) High thermal efficiency-type laminar plasma jet generator for plasma processing. Vacuum 59:47–54

Huang HJ, Pan WX, Guo ZY, Wu CK (2008) Laminar/turbulent plasma jets generated at reduced pressure. IEEE Trans Plasma Sci 36(4, 1):1052–1053

Pan WX, Meng X, Li G, Fei QX, Fei CK, Wu CK (2005) Feasibility of laminar plasma jet hardening of cast iron surface. Surf Coat Technol 197:345–350

Wu GZ, Li T, Pan WX (2006) Laminar plasma sraying of metal wire in atmosphere. Heat Treat Met S1:143–145

Ma W, Fei QX, Pan WX, Wu CK (2006) Investigation of laminar plasma remelting/cladding processing. Appl Surf Sci 252:3541–3546

Langlois-Bertrand E, de Izarra C (2011) Experimental characterization of an argon laminar plasma jet at atmospheric pressure. J Phys D Appl Phys 44:415201

Krowka J, Rat V, Coudert JF (2013) Investigation and control of dc arc jet instabilities to obtain a self-sustained pulsed laminar arc jet. J Phys D Appl Phys 46:505206

Deng J, Li YJ, Xu YX, Sheng HZ (2011) Numerical simulation of fluid flow and heat transfer in a DC non-transferred arc plasma torch operating under laminar and turbulent conditions. Plasma Sci Technol 13(2):201–207

Li G, Pan WX, Meng X, Wu CK (2005) Application of similarity theory to the characterization of non-transferred laminar plasma jet generation. Plasma Sour Sci Technol 14:219–225

Acknowledgments

This research was supported by the National Natural Science Foundation of China (No. 51405315) and the Talents Introduction Project of Sichuan University (No. yj2012043).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miao, J., Yu, D., Cao, X. et al. Experimental Study on the Characteristics of a Miniature Laminar Plasma Torch with Different Gas Flow Patterns. Plasma Chem Plasma Process 35, 879–893 (2015). https://doi.org/10.1007/s11090-015-9632-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-015-9632-y