Abstract

In this paper a three-dimensional isotropic fractional viscoelastic model is examined. It is shown that if different time scales for the volumetric and deviatoric components are assumed, the Poisson ratio is time varying function; in particular viscoelastic Poisson ratio may be obtained both increasing and decreasing with time. Moreover, it is shown that, from a theoretical point of view, one-dimensional fractional constitutive laws for normal stress and strain components are not correct to fit uniaxial experimental test, unless the time scale of deviatoric and volumetric are equal. Finally, the model is proved to satisfy correspondence principles also for the viscoelastic Poisson’s ratio and some issues about thermodynamic consistency of the model are addressed.

Similar content being viewed by others

References

Nutting PG (1921) A new general law of deformation. J Frankl Inst 191:679–685

Bagley RL, Torvik PJ (1984) On the appearance of the fractional derivative in the behavior of real materials. J Appl Mech 51:294–298

Demirci N, Tonuk E (2014) Non-integer viscoelastic constitutive law to model soft biological tissues to in-vivo indentation. Acta Bioeng Biomech 16(4):13–21

Freed AD, Diethelm K (2006) Fractional calculus in biomechanics: a 3D viscoelastic model using regularized fractional derivative kernels with application to the human calcaneal fat pad. Biomech Model Mechanobiol 5:203–215

Kobayashi Y, Kato A, Watanabe H, Hoshi T, Kawamura K, Fujie MG (2012) Modeling of viscoelastic and nonlinear material properties of liver tissue using fractional calculations. J Biomech Sci Eng 7(2):117–187

Alotta G, Di Paola M, Pirrotta A (2014) Fractional Tajimi–Kanai model for simulating earthquake ground motion. Bull Earthq Eng 12(6):2495–2506

Podlubny I (1999) Fractional differential equation. Academic Press, San Diego

Samko GS, Kilbas AA, Marichev OI (1993) Fractional integrals and derivatives. Gordon and Breach Science, Amsterdam

Flugge W (1967) Viscoelasticity. Blaisdell Publishing Company, Waltham

Mainardi F (2010) Fractional calculus and waves in linear viscoelasticity. Imperial College, London

Di Paola M, Pinnola FP, Zingales M (2013) A discrete mechanical model of fractional hereditary materials. Meccanica 48(7):1573–1586

Rossikhin YA, Shitikova MV (1997) Application of fractional derivatives to the analysis of damped vibrations of viscoelastic single mass systems. Acta Mech 120:109–125

Rossikhin YA, Shitikova MV (2016) Dynamic response of a viscoelastic plate impacted by an elastic rod. J Vib Control 22(8):2019–2031

Craiem DO, Rojo FJ, Atienza JM, Guinea GV, Armentano RL (2008) Fractional calculus applied to model arterial viscoelasticity. Lat Am Appl Res 38:141–145

Di Paola M, Fiore V, Pinnola FP, Valenza A (2014) On the influence of the initial ramp for a correct definition of the parameters of fractional viscoelastic materials. Mech Mater 69(1):63–70

Guedes RM (2011) A viscoelastic model for a biomedical ultra-high molecular weight polyethylene using the time–temperature superposition principle. Polym Test 30:294–302

Di Paola M, Heuer R, Pirrotta A (2013) Fractional visco-elastic Euler–Bernoulli beam. Int J Solids Struct 50(22–23):3505–3510

Di Paola M, Failla G, Pirrotta A (2012) Stationary and non-stationary stochastic response of linear fractional viscoelastic systems. Probab Eng Mech 28:8590

Di Lorenzo S, Di Paola M, Pinnola FP, Pirrotta A (2014) Stochastic response of fractionally damped beams. Probab Eng Mech 35:37–43

Fukunaga M, Shimizu N (2015) Fractional derivative constitutive models for finite deformation of viscoelastic materials. J Comput Nonlinear Dyn 10:061002

Hilton HH (2012) Generalized fractional derivative anisotropic viscoelastic characterization. Materials 5:169–191

Makris N (1997) Three-dimensional constitutive viscoelastic laws with fractional order time derivatives. J Rheol 41:1007–1020

Lakes RS (1992) The time-dependent Poisson’s ratio of viscoelastic materials can increase or decrease. Cell Polym 11:466–469

Christensen RM (1982) Theory of viscoelasticity: an introduction. Academic Press, New York

Tschoegl NW, Knauss WG, Emri I (2002) Poisson’s ratio in linear viscoelasticity—a critical review. Mech Time Depend Mater 6:3–51

Lakes RS, Wineman A (2006) On Poisson’s ratio in linearly viscoelastic solids. J Elast 85:45–63

Gemant A (1936) A method of analyzing experimental results obtained from elasto-viscous bodies. Physics 7:311–317

Scott Blair GW, Caffyn JE (1949) An application of the theory of quasi-properties to the treatment of anomalous strain–stress relations. Philos Mag 40(300):80–94

Heymans N, Bauwens JC (1994) Fractal rheological models and fractional differential equations for viscoelastic behavior. Rheol Acta 33:210–219

Schiessel H, Blumen A (1993) Hierarchical analogues to fractional relaxation equations. J Phys A Math Gen 26:5057–5069

Bagley RL, Torvik PJ (1986) On the fractional calculus model of viscoelastic behaviour. J Rheol 30(1):133–155

Adolfsson K, Enelund M, Olsson P (2005) On the fractional order model of viscoelasticity. Mech Time Depend Mater 9:15–34

Van der Varst PGThn, Kortsmit WGE (1992) Notes on the lateral contraction of linear isotropic visco-elastic materials. Arch Appl Mech 62:338–346

Day WA (1970) Restrictions on relaxation functions in linear viscoelasticity. Q J Mech Appl Math 23:1–15

Coleman BD (1964) Thermodynamics of materials with memory. Arch Ration Mech Anal 17:1–46

Deseri L, Di Paola M, Zingales M (2014) Free energy and states of fractional-order hereditariness. Int J Solids Struct 51:3156–3167

Staverman A, Schwarzl T (1952) Thermodynamics of viscoelastic behavior. Ver Akad Can Wet Amst B55:474–485

Acknowledgments

GA wish to acknowledge support from the University of Palermo to visit the University of Oxford during which period this research was conducted. OB would like to acknowledge the Engineering and Physical Sciences Research Council [Programme Grant Number EP/L014742/1].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Appendix

Appendix

The thermodynamic consistency of fractional viscoelastic model has been widely investigated and demonstrated by several authors (see e.g. [31, 32, 34, 35]). In this “Appendix” two cases are studied in order to further confirm the results of other authors, a relaxation test and a dynamic test.

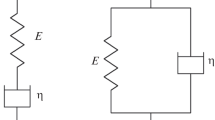

The thermodynamic consistency is usually investigated by imposing non-negative internal work (elastic energy stored in the solid) and non-negative rate of energy dissipation and if these hold what restrictions apply to its parameters in order to respect the conditions. In classical models the internal work is related to the stored energy in the solid, then to the elastic part of strain; the dissipated energy is related to the viscous part of the strain. However in fractional viscoelasticity is not possible to distinguish between elastic and inelastic strain; this is due to the the fact that the springpot model contains in itself the features of both spring and dashpot, as shown by the hierarchical or selfsimilar models that are able to reproduce power law viscoelasticity [11, 29, 30]. To overcome this problem, it is possible to work with state functions and in particular with the concept of free energy (corresponding to the elastic energy) and dissipation rates; indeed, in the paper [36] it has been found what is the right definition of the free energy for the springpot model shown in the following. In this way the free energy itself and the dissipation rate can be evaluated.

The specific Helmotz free energy \(\psi \) is a thermodynamic state function whose gradient with respect to the actual value of strain \(\varepsilon \) gives the measured stress; it represents the energy stored in the solid, that is what in elasticity is defined as elastic energy. The rate of free energy can be expressed as follows:

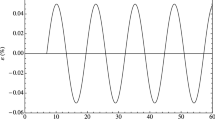

Applied strain histories for the evaluation of free energy and dissipation rate with Eq. (43): sinusoidal (a) and constant with initial linear ramp (b)

where \(\dot{u}\) is the rate of specific internal energy, T is the the absolute temperature and \(\dot{s}\) is the entropy production. The second principle of thermodynamics states that \(\dot{s}\ge \dot{q}/T\), being \(\dot{q}\) the rate of change of specific thermal energy, or simply the rate of thermal energy exchange. It is to be emphasized that:

-

The rate of change of specific internal energy is related to the rate of the specific mechanical work done on the system and on the thermal energy exchange, then \(\dot{u}=\dot{w}_{ext}+\dot{q}\).

-

Introducing the entropy production rate due to irreversible transformations labeled as \(\dot{s}^{(i)}\ge 0\), that is related to the dissipated energy, the second principle of thermodynamics can be written as \(\dot{s}=\dot{q}/T+\dot{s}^{(i)}\).

By performing these two substitutions in Eq. (39) we get:

where \(D(t)=T\dot{s}\) denotes the dissipation rate. When we apply a strain or stress history to the viscoelastic solid, in Eq. (40) the external work rate is known and can be evaluated as \(\dot{w}_{ext}=\sigma (t) \dot{\varepsilon }(t)\). If it is possible to define also the free energy rate then also the dissipation rate can be evaluated from Eq. (40). Unfortunately the free energy is not uniquely defined unless a rheological model with well defined and distinct elastic and viscous phases is available, as it is in classical viscoelasticity. In fractional viscoelasticity the only possibility to distinguish between elastic and viscous phases is to make use of hierarchical models [11, 29, 30] but the number of elements to be taken into account is significant and depends also on the observation time and on the input on the system; for these reasons this strategy is not applicable. However, in the paper [36] the mechanical models of fractional viscoelasticity have been used to prove that the correct form of the free energy function for the fractional viscoelastic material is the one proposed by Stavermann and Schwartzl [37] and defined as:

where \(R(\cdot )\) is the relaxation function as usual and the pedex SS stands for Stavermann and Schwartzl. By using Eq. (41) in Eq. (40), the following expression for the dissipation rate is obtained:

For the particular case of the springpot Eqs. (41) and (42) read as follow:

Equations (43) should be firstly applied to the one-dimensional springpot model and then to the three-dimensional springpot model; however from a one-dimensional point of view the thermodynamic consistency of the springpot has been already proved. In this case in order to evaluate the free energy and the dissipation rate it is needed to take all the components of stress and strain into account from both the volumetric and deviatoric contributions. Limitations on the relationship between \(\alpha \) and \(\beta \) can be found by enforcing the condition that \(\psi (t)\ge 0\;\;\forall t\) and \(D(t)\ge 0\;\;\forall t\). However the analytical solution of the double integrals in Eqs. (43) is not straightforward hence numerical integration has been performed. The analysis is performed for two cases: i) a sinusoidal hystory of strain is applied, but differently from the paper [31], also transient conditions are examined; ii) a constant strain, reached with a linear ramp, is applied.

Equations (43) have been evaluated by considering a large range of values of \(\alpha \) and \(\beta \); the other mechanical parameters (\(G_\alpha \) and \(K_\beta \)) are chosen positive, because negative value of multiplicative parameters violate thermodynamic restrictions also in one-dimensional conditions. For simplicity here we show only results with the following values: (1) \(\alpha =\beta =0.5\); (2) \(\alpha =0.5\), \(\beta =0.25\); (3) \(\alpha =0.5\), \(\beta =0.75\). Figure 8 shows the specific dissipation rate (dissipation rate per unit volume), while Fig. 9 show s the specific free energy function for the two applied strain histories of Fig. 7.

Figures 8 and 9 show that the dissipation rate and the free energy function are non-negative whatever the relationship between the values of \(\alpha \) and \(\beta \) is. From this evidence it has to be concluded that the 3D fractional viscoelastic models are thermodynamically consistent independently of the relationship between \(\alpha \) and \(\beta \); this means that both an increasing and a decreasing viscoelastic Poisson’s ratio are possible for 3D fractional constitutive models that hence are suitable to represent both behaviors.

Rights and permissions

About this article

Cite this article

Alotta, G., Barrera, O., Cocks, A.C.F. et al. On the behavior of a three-dimensional fractional viscoelastic constitutive model. Meccanica 52, 2127–2142 (2017). https://doi.org/10.1007/s11012-016-0550-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-016-0550-8