Abstract

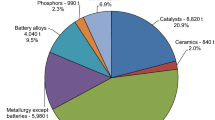

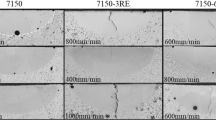

Silicon is a base element used to cast aluminum alloys, and the properties of an Al–Si alloy can be controlled by adjusting the casting and heat treatment parameters. The influence was investigated that the silicon content of Al–Si alloys on the silicon precipitation rate. Silicon was added to pure commercial aluminum at 0.8, 1.5, 3.0, 6.5, and 9.5 mass%, and then, samples were produced through casting. The specimens were solid solution treatment for 10 h at 803 K and were analyzed using a thermomechanical apparatus and differential scanning calorimetry to determine the change of exothermic reaction and the coefficient of thermal expansion (CTE) according to the silicon content in aluminum alloys. The heat flow curve showed an exothermic reaction resulting from silicon precipitation in the matrix, dissolving in the matrix during the solid solution treatment. The CTE curve also indicated silicon precipitation, and the peak value of the CTE reflected the change in temperature at which the silicon precipitation had occurred according the silicon content in the aluminum alloy. The rate of the silicon precipitation appeared to be proportional to the silicon content in the aluminum alloy since the silicon content induced changes in the microstructure of the aluminum alloy and thereby affecting the silicon precipitation kinetics.

Similar content being viewed by others

References

Zolotorevsky VS, Belov NA, Glazoff MV. Casting aluminum alloys. Elsevier; 2010.

Davis JR. Aluminum and aluminum alloys. ASM international; 1993.

Mondolfo LF. Aluminum alloys: structure and properties. Elsevier; 2013.

Tański T, Labisz K, Krupińska B, Krupiński M, Król M, Maniara R, et al. Analysis of crystallization kinetics of cast aluminum–silicon alloy. J Therm Anal Calorim. 2016;123:63–74.

Kattner UR, Massalski TB. Binary alloy phase diagrams. Materials Park, OH: ASM International; 1990. p. 148.

Murray JL, McAlister AJ. The Al–Si (aluminum–silicon) system. Bull Alloy Phase Diagr. 1984;5:74–84.

Schumacher P, Pogatscher S, Starink MJ, Schick C, Mohles V, Milkereit B. Quench-induced precipitates in Al–Si alloys: calorimetric determination of solute content and characterisation of microstructure. Thermochim Acta. 2015;602:63–73.

Lasagni F, Mingler B, Dumont M, Degischer HP. Precipitation kinetics of Si in aluminium alloys. Mater Sci Eng A. 2008;480:383–91.

van Rooyen M, Mittemeijer EJ. Precipitation of silicon in aluminum–silicon: a calorimetric analysis of liquid-quenched and solid- quenched alloys. Metall Trans A. 1989;20:1207–14.

Rosenbaum HS, Turnbull D. Metallographic investigation of precipitation of silicon from aluminum. Acta Metall. 1959;7:664–74.

Starink MJ. Analysis of aluminium based alloys by calorimetry: quantitative analysis of reactions and reaction kinetics. Int Mater Rev. 2004;49:191–226.

Starink MJ, Zahra A-M. Kinetics of isothermal and non-isothermal precipitation in an Al-6 at.% Si alloy. Philos Mag A. 1998;77:187–99.

Brown ME, Gallagher PK. Handbook of thermal analysis and calorimetry: recent advances, techniques and applications. Elsevier; 2011.

Rosenbaum HS, Turnbull D. On the precipitation of silicon out of a supersaturated aluminum–silicon solid solution. Acta Metall. 1958;6:653–9.

van Mourik P, de Keijser TH, Mittemeijer EJ. Kinetics of precipitation and of relaxation of precipitation-induced stresses in aluminium–silicon alloys. Scr Metall. 1987;21:381–5.

Segers D, van Mourik P, van Wijngaarden MH, Rao BM. Precipitation of silicon in a solid quenched aluminium–silicon (1.3 at.%) alloy studied by positron annihilation BY. Phys Status Solidi. 1984;209:209–16.

Rometsch PA, Starink MJ, Gregson PJ. Improvements in quench factor modelling. Mater Sci Eng A. 2003;339:255–64.

Abbaschian R, Abbaschian L, Reed-Hill RE. Physical metallurgy principles. New York: Van Nostrand; 1973.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, YM., Kang, DS., Hong, SK. et al. Influence of variation in the silicon content on the silicon precipitation in the Al–Si binary system. J Therm Anal Calorim 128, 107–113 (2017). https://doi.org/10.1007/s10973-016-5840-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5840-9