Abstract

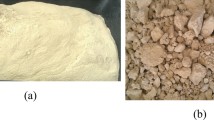

Tailings from tungsten mining activities in the vicinity of Barruecopardo (Salamanca) represent high environmental pollution. In this paper we present a study of the use of these wastes as raw materials for the manufacture of glass. This procedure aims to contribute to environmental remediation of mining areas through vitrification, a process which offers an alternative for stabilization of hazardous wastes. In addition, the marketing of the obtained product would provide an additional income to the mining areas. The chemical composition of the tailings to be used as raw materials was determined by X-ray fluorescence and their mineralogy by X-ray diffraction. Wastes are of granitic composition enriched in potentially toxic elements. For this study, a representative sample of mining wastes of sandy grain size was used to make the glass. On the basis of its composition, glass was formulated by adding 29.28 mass% of CaCO3 and 14.03 mass% of Na2CO3 and a green glass was produced. Crystallisation temperatures, obtained by DTA, were 875 and 1022 °C and the melting temperature was 1175 °C. The transition temperature of glass was of 644 °C. The temperatures for the fixed viscosity points, and the working temperatures were obtained. A thermal treatment induced devitrification to produce a glass–ceramic made of nepheline and wollastonite. Leaching tests of the obtained glass confirm its capacity to retain potentially toxic elements.

Similar content being viewed by others

References

Garcia-Sanchez A, Alvarez-Ayuso E. Arsenic in soils and waters and its relation to geology and mining activities (Salamanca Province, Spain). J Geochem Explor. 2003;80:69–79.

Otones V, Álvarez-Ayuso E, García-Sánchez A, Santa Regina I, Murciego A. Arsenic distribution in soils and plants of an arsenic impacted former mining area. Environ Pollut. 2011;159:2637–47.

Murciego A, Álvarez-Ayuso E, Pellitero E, Rodríguez MA, García-Sánchez A, Tamayo A, Rubio J, Rubio F, Rubin J. Study of arsenopyrite weathering products in mine wastes from abandoned tungsten and tin exploitations. J Hazard Mater. 2011;2011(186):590–601.

European Commision. Report on critical raw materials, European Union. http://ec.europa.eu/DocsRoom/documents/10010/attachments/1/translations/en/renditions/native (2014). Accessed 1 Jun 2015.

Bingham PA, Hand RJ. Vitrified metal finishing wastes: I. Composition, density and chemical durability. J Hazard Mater. 2005;119:125–33.

Bingham PA, Hand RJ, Forder SD, Lavaysierre A. Thermal and structural characterisation. J Hazard Mater. 2005;122:129–38.

Binhussain MA, Marangoni M, Bernardo E, Colombo P. Sintered and glazed glass-ceramics from natural and waste raw materials. Ceram Int. 2014;40:3543–51.

Pérez JA, Terradas R, Seijas MM, Manent R, Martínez S. Inertization of industrial wastes in ceramics materials. Ind Ceram. 1996;16:7–11.

Haugsten KE, Gustavson B. Environmental properties of vitrified fly ash from hazardous and municipal waste incineration. Waste Manag. 2000;20:167–76.

Garcia-Valles M, Avila G, Martinez S, Terradas R, Nogués JM. Heavy metal-rich wastes sequester in mineral phases through a glass–ceramic process. Chemosphere. 2007;68:1946–53.

Rangel BF, Viana MM, Fonseca MVA, Dweck J, Tavares LM. Thermal characterization of a new green ceramic material by heating microscopy, thermogravimetry and differential thermal analysis. J Therm Anal Calorim. 2015;121:115–25.

Raigon-Pichardo M, Garcia-Ramos G, Sanchez-Soto PJ. Characterization of a waste washing solid product of mining granitic tin-bearing sands and its application as a ceramic raw material. Resour Conserv Recycl. 1996;17:109–24.

Ferreira JMF, Torres PMC, Silva MS, Labrincha JA. Recycling of granite sludge in brick-type and floor tile-type ceramic formulations. Euroceram News. 2003;14:1–5.

Monteiro SN, Peçanha LA, Vieira CMF. Reformulation of roofing tiles body with addition of granite waste from sawing operations. J Eur Ceram Soc. 2004;24:2349–56.

Segadães AM, Carvalho MA, Acchar W. Usingmarble and granite rejects to enhance the processing of clay products. Appl Clay Sci. 2005;30:42–52.

Hojamberdiev M, Eminov A, Yunhua X. Utilization of muscovite granite waste in the manufacture of ceramic tiles. Ceram Int. 2010;37:871–6.

Liu CP, Luo CL, Gao Y, Li FB, Lin LW, Wu CA, Li XD. Arsenic contamination and potential health risk implications at an abandoned tungsten mine, southern China. Environ Pollut. 2010;158:820–6.

Peng K, Lv C, Yang H. Novel preparation of glass ceramics from amorphized tungsten tailings. Ceram Int. 2014;40:10291–6.

Durán Suárez J, Montoya Herrera J, Silva AP, Peralbo Cano R, Castro-Gomes JP. Validación de nuevos materiales cerámicos a partir de rocas de desecho de minería. Propiedades Mecánicas. 2014;53:279–88.

Castro-Gomes JP, Silva AP, Peralbo Cano R, Durán Suárez J, Albuquerque A. Potential for reuse of tungsten mining waste-rock in technical-artistic value added products. J Clean Prod. 2012;25:34–41.

CIE 1931. Proceedings of the eighth session. England: Cambridge; 1931. p. 19–29.

Engels M, Link S. Bubble control in ceramic glazes. Interceram. 2006;3:152–6.

Der Scholze H. Einfluss von Viskosität und Oberflächenspannung auf erhitzungsmikroskopische Messungen an Gläsern. Ber Dtsch Keram Ges. 1962;39:63–8.

DIN. Determination of ash fusion behaviour. German Standard, DIN 51730; 1976.

Garcia-Valles M, Hafez H, Cruz-Matías I, Vergés E, Aly MH, Nogués JM, Ayala D, Martinez S. Calculation of viscosity–temperature curves for glass obtained from four wastewater treatment plants in Egypt. J Therm Anal Calorim. 2013;111:107–14.

Fuegel A. Glass viscosity calculation based on a global statistical modeling approach. Glass Technol Eur J Glass Sci Technol. 2007;48:13–30.

EPA. Test methods for evaluating solid waste: physical/chemical methods SW-846. 3rd ed. Washington: Office of Solid Waste and Emergency Response; 1986.

Garcia-Valles M, Aly MH, El-Fadaly E, Hafez H, Nogués JM, Martinez S. Producción de materiales vitrocerámicos obtenidos a partir de lodos procedentes de una estación de depuración de aguas residuales urbanas en la Ciudad de El-Sadat (Egipto). Bol Soc Esp Ceram Vidr. 2011;50:219–28.

Arancibia JRH, Alfonso P, García-Valles M, Martínez S, Parcerisa D, Canet C, Romero FM. Obtención de vidrio a partir de residuos de la minería del estaño en Bolivia. Bol Soc Esp Ceram Vidr. 2013;52:143–50.

Fernandez Navarro JM. El Vidrio. 3rd ed. Madrid: CSIC y Sociedad Española de Cerámica y Vidrio; 2003.

Acknowledgements

This work is part of the OptimOre project. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 642201. Funds from the Fundació Bosch I Gimpera Project 307466 and the Consolidated Group for Research of Mineral Resources, 2014 SGR-1661 (Recursos Minerals: jaciments, aplicacions, sostenibilitat) were contributed. The authors would like to thank the staff of the Centres Científics I Tecnològics of the University of Barcelona (CCiTUB) for their technical support. M. Tarragó received a PhD grant from the Ministerio de Educación, Cultura y Deporte (FPU13/04507).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alfonso, P., Castro, D., Garcia-Valles, M. et al. Recycling of tailings from the Barruecopardo tungsten deposit for the production of glass. J Therm Anal Calorim 125, 681–687 (2016). https://doi.org/10.1007/s10973-016-5332-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5332-y