Abstract

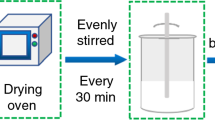

Stearic acid/diatomite composite form-stable phase change materials (PCMs) have been prepared by using a direct impregnation method without vacuum treatment. The surface morphology, chemical compatibility, thermal properties and thermal stability were characterized by scanning electron microscopy, Fourier transform infrared spectrometer and X-ray diffraction (XRD), differential scanning calorimeter and thermogravimetric analysis (TG), respectively. The results show that there are only physical interactions between stearic acid and diatomite in composite PCM. XRD analysis reveals that crystal type is not affected by composite technology of SA/diatomite composite form-stable PCM with decrease in crystal size due to the limited pores in diatomite. The melting and freezing temperatures of stearic acid/diatomite composite, respectively, are 52.3 and 48.4 °C. The latent heat of SA/diatomite composite reaches 57.1 J g−1, potential to be used in a practical application. TG result indicates that the decomposition of SA/diatomite composite starts at 192 °C, implying that the SA/diatomite has a good thermal stability.

Similar content being viewed by others

References

Sanchez L, Sanchez P, Lucas A. Microencapsulation of PCMs with a polystyrene shell. Colloid Polym Sci. 2007;285:1377–85.

Li W, Song G, Tang G, Chu X, Ma S, Liu C. Morphology, structure and thermal stability of microencapsulated phase change material with copolymer shell. Energy. 2010;36:785–91.

Giro-Paloma J, Konu klu Y, Fernandez A. Preparation and exhaustive characterization of paraffin or palmitic acid microcapsules as novel phase change material. Sol Energy. 2015;112:300–9.

He F, Wang X, Wu D. Phase-change characteristics and thermal performance of form-stable n-alkanes/silica composite phase change materials fabricated by sodium silicate precursor. Renew Energy. 2015;74:689–98.

Yang X, Yuan Y, Zhang N, Cao X, Liu C. Preparation and properties of myristic–palmitic–stearic acid/expanded graphite composites as phase change materials for energy storage. Sol Energy. 2014;99:259–66.

Fang X, Fan L, Ding Q, Yao X, Wu Y, Hou J, Wang X, Yu Z, Chneg G, Hu Y. Thermal energy storage performance of paraffin-based composite phase change materials filled with hexagonal boron nitride nanosheets. Energy Convers Manag. 2014;80:103–9.

Zhang Z, Fang X. Study on paraffin/expanded graphite composite phase change thermal energy storage material. Energy Convers Manag. 2006;47:303–10.

Sari A, Karaipekli A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl Therm Eng. 2007;27:1271–7.

Wang L, Meng D. Fatty acid eutectic/polymethyl methacrylate composite as form-stable phase change material for thermal energy storage. Appl Energy. 2010;87:2660–5.

Tyagi V, Kaushik S, Tyagi S, Akiyama T. Development of phase change materials based microencapsulated technology for buildings: a review. Renew Sustain Energy Rev. 2011;15:1373–91.

Sun Z, Zhang Y, Zheng S, Park Y, Frost R. Preparation and thermal energy storage properties of paraffin/calcined diatomite composites as form-stable phase change materials. Thermochim Acta. 2013;558:16–21.

Sanchez L, Sanchez P, Lucas A. Microencapsulation of PCMs with a polystyrene shell. Colloid Polym Sci. 2007;285:1377–85.

Song Q, Li Y, Xing J, Hu J, Marcus Y. Thermal stability of composite phase change material microcapsules incorporated with silver nano-particles. Polymer. 2007;48:3317–23.

Xu B, Li Z. Paraffin/diatomite composite phase change material incorporated cement-based composite for thermal energy storage. Appl Energy. 2013;105:229–37.

Yang X, Yuan Y, Zhang N, Cao X, Liu C. Preparation and properties of myristic–palmitic–stearic acid/expanded graphite composites as phase change materials for energy storage. Sol Energy. 2014;99:259–66.

Xu B, Li Z. Paraffin/diatomite/multi-wall carbon nanotubes composite phase change material tailor-made for thermal energy storage cement-based composites. Energy. 2014;72:371–80.

Li M, Wu Z, Kao H. Study on preparation and thermal properties of binary fatty acid/diatomite shape-stabilized phase change materials. Sol Energy Mater Sol Cells. 2011;95:2412–6.

Li M, Kao H, Wu Z, Tao J. Study on preparation and thermal property of binary fatty acid and the binary fatty acids/diatomite composite phase change materials. Appl Energy. 2011;88:1606–12.

Li M, Wu Z, Kao H. Study on preparation, structure and thermal energy storage property of capric–palmitic acid/attapulgite composite phase change materials. Appl Energy. 2011;88:3125–32.

Sari A, Bicer A. Thermal energy storage properties and thermal reliability of some fatty acid esters/building material composites as novel form-stable PCMs. Sol Energy Mater Sol Cells. 2012;101:114–22.

Karaman S, Karaipekli A, Sari A, Bicer A. Polyethylene glycol (PEG)/diatomite composite as a novel form-stable phase change material for thermal energy storage. Sol Energy Mater Sol Cells. 2011;95:1647–53.

Fu X, Liu Z, Xiao Y, Wang J, Lei J. Preparation and properties of lauric acid/diatomite composites as novel form-stable phase change materials for thermal energy storage. Energy Build. 2015;104:244–9.

Xu B, Li Z. Paraffin/diatomite composite phase change material incorporated cement-based composite for thermal energy storage. Appl Energy. 2013;105:229–37.

Sari A, Alkan C, Altintas A. Preparation, characterization and latent heat thermal energy storage properties of micro-nanoencapsulated fatty acids by polystyrene shell. Appl Therm Energy. 2014;73:1160–8.

Yuan Y, Zhang N, Tao W, Cao X, He Y. Fatty acids as phase change materials: a review. Renew. Renew Sustain Energy Rev. 2014;29:482–98.

Zhou D, Zhao C, Tian Y. Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl Energy. 2012;92:593–605.

Zhang X, Fan Y, Tao X, Yick K. Crystallization and prevention of supercooling of microencapsulated n-alkanes. J Colloid Interface Sci. 2005;281:299–306.

Karaipekli A, Sari A. Capric–myristic acid/vermiculite composite as form-stable phase change material for thermal energy storage. Sol Energy. 2009;83:323–32.

Li M, Wu Z, Kao H, Tan J. Experimental investigation of preparation and thermal performances of paraffin/bentonite composite phase change material. Energy Convers Manag. 2011;52:3275–81.

Zhou X, Xiao H, Feng J. Preparation and thermal properties of paraffin/porous silica ceramic composite. Colloid Polym Sci. 2009;69:1246–9.

Mei D, Zhang B, Liu R, Zhang Y, Liu J. Preparation of capric acid/halloysite nanotube composite as form-stable phase change material for thermal energy storage. Sol Energy Mater Sol Cells. 2011;95:2772–7.

Karaipekli A, Sari A. Capric–myristic acid/vermiculite composite as form-stable phase change material for latent heat thermal energy storage. Renew Energy. 2008;33:2599–605.

Rozanna D, Salmiah A, Chuah T, Medyan R, Thomas Choog SY, Saari M. A study on thermal characteristics of phase change material (PCM) in gypsum board for building application. J Oil Palm Res. 2005;17:41–6.

Fu X, Kong W, Zhang Y, Jiang L, Wang J, Lei J. Novel solid–solid phase change materials with biodegradable trihydroxy surfactants for thermal energy storage. RSC Adv. 2015;5:68881–9.

Genc ZK, Canbay CA, Acar SS, Sekerci M, Genc M. Preparation and thermal properties of heterogeneous composite phase change materials based on camphene–palmitic acid. J Therm Anal Calorim. 2015;120:1679–88.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, X., Liu, Z., Wu, B. et al. Preparation and thermal properties of stearic acid/diatomite composites as form-stable phase change materials for thermal energy storage via direct impregnation method. J Therm Anal Calorim 123, 1173–1181 (2016). https://doi.org/10.1007/s10973-015-5030-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-5030-1