Abstract

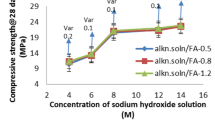

This paper reports the investigated thermogravimetry analysis, compressive strength and thermal conductivity tests of non-autoclaved aerated Portland cement–fly ash–silica fume concrete. The mixes were cured in water and air for 3, 7 and 28 days. Thermogravimetry results showed that calcium silicate hydrate (C–S–H), ettringite, gehlenite (C2ASH8), calcium hydroxide [Ca(OH)2] and calcium carbonate (CaCO3) phases were detected in all mixes. The compressive strength and thermal conductivity of aerated Portland cement–fly ash–silica fume concrete increased when compared with aerated Portland cement–fly ash concrete after 28 days. The compressive strength and thermal conductivity of aerated concrete cured in water had higher values than air-cured specimens. X-ray diffraction and thermogravimetry showed that Ca(OH)2 decreased with increased silica fume content. This is due to the increased pozzolanic reaction when compared with the Portland cement–fly ash mixes, which corresponds to an increase in compressive strength and thermal conductivity.

Similar content being viewed by others

References

World Business Council for Sustainable Development. Cement Technology Roadmap 2009, Carbon Emissions reductions up to 2050: OECD/IEA and the World Business Council for Sustainable Development; 2009.

Damtoft J, Lukasik J, Herfort D, Sorrentino D, Gartner E. Sustainable development and climate change initiatives. Cem Concr Res. 2008;38(2):115–27.

Nehdi M, Mindess S, Aitcin PC. Use of ground lime stone in concrete: a new look. Bull Res J. 1995;43(4):245.

Zeng Q, Li K. Reaction and microstructure of cement–fly ash system. Mater Struct. 2014. doi:10.1617/s11527-014-0266-y.

Ben Haha M, De Weerdt K, Lothenbach B. Quantification of degree of reaction of fly ash. Cem Concr Res. 2010;40:1620–9.

Papadakis VJ. Effect of fly ash on Portland cement systems. Part I: low calcium fly ash. Cem Concr Res. 1999;29:1727–36.

Lam L, Wong YL, Poon CS. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem Concr Res. 2000;30:747–56.

Han SH, Kim JK, Park YD. Prediction of compressive strength of fly ash concrete. Cem Concr Res. 2003;33:965–71.

Willinska I, Pacewska B. Calorimeter and thermal analysis studies on the influence of waste aluminosilicate catalyst on the hydration of fly ash–cement paste. J Therm Anal Calorim. 2014;116:689–97.

Elsayed AA. Influence of silica fume, fly ash, super pozz, and high slag cement on water permeability and strength of concrete. Concr Res Lett. 2012;3(4):528–40.

Alasali MM, Malhotra VM. Role of concrete incorporating high volume of fly ash in controlling expansion due to alkali–aggregate reaction. ACI Mater J. 1991;88(2):159–63.

Carette G, Bilodeau A, Chevrier RL, Malhotra VM. Mechanical properties of concrete incorporating high volume fly ash from sources in the US. ACI Mater J. 1993;90(6):535–44.

Naik TR, Singh SS, Ramme BW. Mechanical properties and durability of concrete made with blend fly ash. ACI Mater J. 1998;95(4):454–62.

Baert G, Horste S, Schutter G, Belie N. Reactivity of fly ash in cement paste studied by means of thermogravimetry and isothermal calorimetry. J Therm Anal Calorim. 2008;94:485–92.

Vessalas K, Thomas PS, Ray AS, Guerbois JP, Joyce P, Haggman J. Pozzolanic reactivity of the supplementary cementitious materials pitchstone fines by thermogravimetric analysis. J Therm Anal Calorim. 2009;97:71–6.

Malhotra VM, Metha PK. Pozzolanic and cementitious materials, advances in concrete technology. London: Gordon and Breach; 1996.

Chung DDL. Review improving cement-based materials by using silica fume. J Mater Sci. 2002;37:673–82.

Rong ZD, Sun W, Xiao HJ, Wang W. Effect of silica fume and fly ash on hydration and microstructure evolution of cement based composite at low water–binder ratio. Constr Build Mater. 2014;51:446–50.

Korpa A, Kowald T, Trettin R. Hydration behavior, structure and morphology of hydration phases in advanced cement-based systems containing micro and nanoscale pozzolanic additives. Cem Concr Res. 2008;38:955–65.

Kohno K, Aihara F, Ohna K. Relative durability properties and strength of mortars containing finely ground silica and silica fume. In: Malhotra VM, editor. Proceedings of the third congress on fly ash, silica fume, slag and national pozzolans in concrete. ACI SP 114. vol 1; 1989. p. 815.

Chaipanich A, Nochaiya T. Thermal analysis and microstructure of Portland cement–fly ash–silica fume paste. J Therm Anal Calorim. 2010;99:487–93.

Yazici H. The effect of silica fume and high-volume class c fly ash on mechanical properties, chloride penetration and freeze–thaw resistance of self-compact concrete. Constr Build Mater. 2008;22:456–62.

Valipour M, Pargar F, Shekarchi M, Khani S. Comparing the natural pozzolan, zeolite, to metakaolin and silica fume in term of their effect on the durability characteristics of concrete: a laboratory study. Constr Build Mater. 2013;41:879–88.

Li Y, Sun D, Wu X, Wang A, Xu W, Deng M. Drying shrinkage and compressive strength of blended cement pastes with fly ash and silica fume. Adv Mater Res. 2012;535–537:1735–8.

Lai WL, Tsang WF. Characterization of pore systems of air/water-cured concrete using ground penetrating radar (GPR) through continuous water injection. Constr Build Mater. 2008;22:250–6.

Neville AM. Properties of concrete. London: Longman; 1995.

Narayanan N, Ramamurthy K. Structure and properties of aerated concrete: a review. Cem Concr Compos. 2000;22:321–9.

Baspinar MS, Demir I, Kahraman E, Gorhan G. Utilization of fly ash together with silica fume in autoclaved aerated concrete production. J Civ Eng. 2014;18(1):47–52.

Just A, Middendorf B. Microstructure of high-strength foam concrete. Mater Charact. 2009;60:741–8.

Wongkeo W, Thongsanitgarn P, Chaipanich A. Compressive strength of binary and ternary of blended cement mortars containing fly ash and silica fume under autoclave curing. Adv Mater Res. 2012;343:316–21.

Wongkeo W, Thongsanitgarn P, Chindaprasirt P, Chaipanich A. Thermogravimetry of ternary cement blends, effect of different curing methods. J Therm Anal Calorim. 2013;113:1079–90.

Holt E, Raivio P. Use of gasification residues in aerated autoclaved concrete. Cem Concr Res. 2005;35:796–802.

Kunchariyakun K, Asavapisit S, Sombatsompop K. Properties of autoclaved aerated concrete incorporating rice husk ash as partial replacement for fine aggregate. Cem Concr Compos. 2015;55:11–6.

ASTM C33-02. Standard specification for concrete aggregates. American Society for Testing and Materials; 2002.

Hamad AJ. Materials, production, properties and application of aerated lightweight concrete: review. Int J Mater Sci Eng. 2014;2:152–7.

ASTM C109. Standard test method for compressive strength of hydraulic cement mortars (Using 2-in. or [50-mm] cube specimens). American Society for Testing and Materials; 2002.

ASTM D 5930-01. Standard test method for thermal conductivity of plastics by means of transient line source technique. American Society for Testing and Materials; 2002.

Wongkeo W, Chaipanich A. Compressive, microstructure and thermal analysis of autoclave and air cured structural lightweight concrete made with coal bottom ash and silica fume. Mater Sci Eng A. 2010;567:3676–84.

Shih JY, Chang TP, Hsiao TC. Effect of nanosilica on characterization of Portland cement composite. Mater Sci Eng A. 2006;424:266–74.

Nochaiya T, Wongkeo W, Chaipanich A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel. 2010;89:768–74.

Guneyisi E, Gesoglu M, Booya E, Mermerdas K. Strength and permeability properties of self-compacting concrete with cold bonded fly ash lightweight aggregate. Constr Build Mater. 2015;74:17–24.

Yuanming S, Jueshi Q, Jinxiang L, Bo W, Yingchum W. Effect of conditions on the hydration and performance of CFBC ash cementitious system. Mater Sci Ed. 2014. doi:10.1007/s11595-014-0873-z.

Mindess S, Young JF, Darwin D. Concrete. 2nd ed. London: Pearson Education; 2003.

Bentz DP, Stutzman PE. Evolution of porosity and calcium hydroxide in laboratory concretes containing silica fume. Cem Concr Res. 1994;24:1044–50.

Albayrak M, Yorukoglu A, Karahan S, Atlihan S, Aruntas HY, Girgin I. Influence of zeolite additive on properties of autoclaved aerated concrete. Build Environ. 2007;42:3161–5.

Demirboga R, Gul R. The effect of expanded perlite aggregate, silica fume, fly ash on thermal conductivity of lightweight concrete. Cem Concr Res. 2003;33:723–7.

Demirboga R. Influence of mineral admixtures on thermal conductivity and compressive strength of mortar. Energy Build. 2003;35:189–92.

Zongjin L. Advanced concrete technology. New York: Wiley; 2011.

Galan I, Andrade C, Castellote M. Thermogravimetrical analysis for monitoring carbonation of cementitious materials, uptake of CO2 and depending in C–S–H knowledge. J Therm Anal Calorim. 2012;110:309–19.

Hamidi M, Kacimi L, Cyr M, Clastres P. Evaluation and improvement of pozzolanic activity of andesite for its use in eco-efficient cement. Constr Build Mater. 2013;47:1268–77.

Alarcon Ruiz L, Platret G, Massieub E, Ehrlacher A. The use of thermal analysis in assessing the effect of temperature on a cement pastes. Cem Concr Res. 2005;35:609–13.

Neves A Jr, ToledoFilho RD. Early stage hydration of high initial strength Portland cement Part I. Thermogravimetric analysis on calcine mass basis. J Therm Anal Calorim. 2012;108:725–31.

Bai J, Chaipanich A, Kinuthia JM, Farrel MO, Sabir BB, Wild S, et al. Compressive strength and hydration of wastepaper sludge ash–ground granulated blast furnace slag blended pastes. Cem Concr Res. 2003;33:1189–202.

Mitchell LD, Margeson JC. The effects of solvents on C–S–H as determined by thermal analysis. J Therm Anal Calorim. 2006;86(3):591–4.

Pandey SP, Sharma RL. The influence of mineral additives on the strength and porosity of OPC mortar. Cem Concr Res. 2000;30:19–23.

Lo Y, Lee HM. Curing on carbonation of concrete using a phenolphthalein indicator and fourier-transform infrared spectroscopy. Build Environ. 2002;37:507–14.

Antoni M, Rossen J, Martirena F, Scrivener K. Cement substitution by a combination of metakaolin and limestone. Cem Concr Res. 2012;42:1579–89.

Dweck J, Ferreira da Silva PF, Buchler PM, Cartledge FK. Study by thermogravimetry of the evolution of ettringite phase during type II Portland cement hydration. J Therm Anal Calorim. 2002;69:179–86.

Acknowledgements

The authors gratefully acknowledged the Office of the Higher Education Commission (OHEC), the Thailand Research Fund (TRF), Department of Physics and Materials Science, Faculty of Science, Chiang Mai University, and the Graduate School of Chiang Mai University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Narattha, C., Thongsanitgarn, P. & Chaipanich, A. Thermogravimetry analysis, compressive strength and thermal conductivity tests of non-autoclaved aerated Portland cement–fly ash–silica fume concrete. J Therm Anal Calorim 122, 11–20 (2015). https://doi.org/10.1007/s10973-015-4724-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4724-8