Abstract

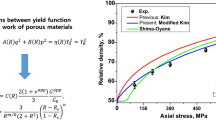

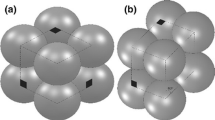

An understanding of the overall porous copper behavior is developed through the combination of real data from microstructures and the fundamental material characteristics of the constitutive phases. Captured morphological images, using the Nano-CT are utilized to generate the geometric information. Object-oriented finite element (OOF) analysis is quite a novel numerical approach to incorporate morphological images, acquired from scanning electron microscopy into 2-D finite element modeling. This paper seeks to investigate the porosities using two methods (Archimedes principle and Nano-CT) and then to introduce an image-based extended OOF modeling technique based on mapping the real microstructures of porous copper and gage its ability to predict the elastic moduli and evaluate the deformation mechanism resulting from the porous copper. Dissolution sintering technique was used by mixing Cu powders with NaCl in the volume ratio of 1:1 and 1:3 adding polyvinyl alcohol solution as a binder with NaCl as the space holder. The green form was pressed at 375 MPa using a four-column hydraulic lab press. The NaCl was leached out in hot water at 70 °C and then sintered to a temperature of 850 °C. Porosity values were determined from density measurements to give the porosity values of 42.2 and 45.71 % for volume ratio of 1:1 and 1:3, respectively. The material properties were obtained from the tests and compared to previous literature. Very good agreement has been shown, establishing the viability of this kind of morphology-based numerical approach.

Similar content being viewed by others

References

A.K. Shaik Dawood, S.S. Mohamed Nazirudeen, A development of technology for making porous metal foams castings. Jordan J. Mech. Ind. Eng. 4, 292–299 (2010)

F. Azarmi, T. Coyle, J. Mostaghimi, Young’s modulus measurement and study of the relationship between mechanical properties and microstructure of air plasma sprayed alloy 625. Surf. Coat. Technol. 203(8), 1045–1054 (2009). doi:10.1016/j.surfcoat.2008.09.035

S.R. Bakshi, A. Bhargava, S. Mohammadizadeh, A. Agarwal, I. Tsukanov, Computational estimation of elastic properties of spark plasma sintered TaC by meshfree and finite element methods. Comput. Mater. Sci. 50(9), 2615–2620 (2011). doi:10.1016/j.commatsci.2011.04.003

J. Banhart, J. Baumeister, Production Methods for Metallic Foams (1999, 1998)

G. Castro, Metallic Syntactic Foams Synthesis, Characterization and Mechanical Properties. (Doctor of Philosophy), Unversity of Southren California (2013)

N. Chawla, Y.-L. Shen, Mechanical behavior of particle reinforced metal matrix composites. Adv. Eng. Mater. 3, 357–370 (2001)

Y. Dong, D. Bhattacharyya, P. Hunter, Experimental characterisation and object-oriented finite element modelling of polypropylene/organoclay nanocomposites. Compos. Sci. Technol. 68(14), 2864–2875 (2008). doi:10.1016/j.compscitech.2007.10.026

S.A. Langer, E.R. Fuller Jr, W.C. Carter, OOF: an imagebased finite-element analysis of material microstructures. Comput. Sci. Eng. 3, 15–23 (2001)

A. Reid, S.A. Langer, R.C. Lua, V.R. Coffman, S. Seung-Ill Haan, R.E. Garcıa, Image-based finite element mesh construction for material microstructures. Comput. Mater. Sci. 43, 989–999 (2008)

A.J. Shih, Z. Huang, Three-dimensional optical measurements of porous foams. J. Manuf. Sci. Eng. 128(4), 951 (2006). doi:10.1115/1.2194556

Acknowledgments

We acknowledge the Center for Composite Materials Research and the National Science Foundation: “MRI-R2: Acquisition of a Nanotom Computed Tomography System for Revolutionizing Metallic Biomaterials Research, Education, and Training at NCAT”. The authors also would like to thank Dr. Boyce Collins and John Skujins who assisted throughout this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Waters, C., Salih, M. & Ajinola, S. Porosity comparative analysis of porous copper and OOF modelling. J Porous Mater 22, 989–995 (2015). https://doi.org/10.1007/s10934-015-9973-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-015-9973-1