Abstract

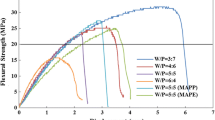

In this study, water absorption, thickness swelling and decay resistance of thermoplastic composites treated with three types of boron compounds was investigated. Spruce wood flour was treated with boric acid (BA), borax (BX) and mixture of BA–BX, and then was reinforced at two loading rate (20 and 40 wt%) in polymer matrix. Decay test of the composites was performed using with a brown rot fungus Coniophora puteana and a white rot fungus Trametes versicolor both for leached and unleached samples. The morphologic evaluations of decayed samples were done by scanning electron microscopy. Composites containing higher wood flour loading resulted in increased water absorption, thickness swelling, weight loss and moisture content. Fungal decay susceptibility of WPCs was influenced by leaching test for 60 days. Boron compound treated composites showed higher weight loss and moisture content than controls in decay test. All tested performance parameters were considerably increased in BX containing composites.

Similar content being viewed by others

References

Manning MJ, Ascherl FM, Mankowski ME (2006) In: 37th IRG annual conference, IRG/WP 06-40351, Tromsø, Norway

Mankowski M, Morrell JJ (2000) Wood Fiber Sci 32(3):340

Verhey SA, Laks PE, Richter D (2001) For Prod J 51(9):44

Ibach RE, Rowell RM, Lange SE, Schumann RL (2002) In: Sixth international conference on wood fiber-plastic composites, Madison, USA, pp 267–270

Pendleton DR, Hoffard TA, Adcock T, Woodward B, Wolcott MP (2002) For Prod J 52(6):21

Verhey SA, Laks PE (2002) In: Enhancing the durability of engineered wood products, Madison, USA, pp 179–189

Ibach RE, Clemons CM, Stark NM (2003) In: Seventh international conference on wood fiber-plastic composites (and other natural fibers), Madison, USA, pp 61–67

Simonsen J, Freitag CM, Silva A, Morrell JJ (2004) Holzforschung 58:205

Schirp A, Wolcott PW (2005) Wood Fiber Sci 37(4):643

Khavkine M, Kazayawoko M, Law S, Balatinecz JJ (2000) Int J Polym Mater 46:255

Silva A, Gartner BL, Morrell JJ (2007) J Test Eval 35(3):203

Lu JZ, Duan X, Wu Q, Lian K (2008) Bioresour Technol 99(13):5906

Lomeli Ramirez MG, Ochoa Ruiz HG, Fuentes Talavera FJ, García Enriquez S, Cerpa Gallegos MA, Silva Guzmán JA (2009) Int Biodeter Biodegr 63:1030

Fabiyi JS, McDonald AG, Morrell JJ, Freitag C (2011) Compos A 42:501

Segerholm K (2012) Doctoral Thesis, KTH Building Materials Technology, Stockholm, p 66

Hamzeh Y, Ashori A, Marvast EH, Rashedi K, Olfat AM (2012) Compos B 43:2409

Kartal SN, Aysal S, Terzi E, Yilgör N, Yoshimura T, Tsunoda K (2013) Bioresources 8:1222

Tascioglu T, Yoshimura T, Tsunoda K (2013) Compos B 51:185

Ashori A, Behzad HM, Tarmian A (2013) Compos B 47:308

Shalbafan A, Benthien JT, Lerche H (2016) BioResources 11(2):4935

Sun G, Ibach RE, Faillace M, Gnatowski M, Glaeser JA, Haight J (2016) Wood Mater Sci Eng. doi:10.1080/17480272.2016.1164755

Morris PI, Cooper P (1998) For Prod J 48:86

Schauwecker C, Morrell JJ, McDonald AG, Fabiyi JS (2006) For Prod J 56:123

Ayrilmis N, Kaymakci A (2013) Ind Crops Prod 43:457

Gardner DJ, Tascioglu C, Wålinder ME Wood deterioration, preservation: advances in our changing world, ACS symposium series 845, Washington D.C., pp 399–419

Wechsler A, S. Hiziroglu (2007) Build Environ 42(7):2637

Ren Y, Wang Y, Wanga L, Liu T (2015) Constr Build Mater 76:273

Cavdar AD, Mengeloglu F, Karakus K (2015) Measurement 60:6

Turku I, Karki T (2016) Fire Mater 40(3):498

Kurt R, Mengeloğlu F (2011) Turk J Agric For 35:155

Akbulut T, Ayrilmis N, Dundar T, Durmus A, White RH, Teker M (2011) Int J Polym Technol 3(2):67

Kurt R, Mengeloğlu F, Meric H (2012) Eur J Wood Prod 70:177

Ayrilmis N, Akbulut T, Dundar T, White RH, Mengeloglu F, Buyuksari U, Candan Z, Avci E (2012) Constr Build Mater 33:63

Clemons CM, Ibach RE (2004) For Prod J 54(4):50

Hosseinihashemi SK, Arwinfar F, Najafi A, Nemli G, Ayrilmiş N (2016) Measurement 86:202

Aysal S (2014) Master Thesis, İU Institute of Science, Technology, Istanbul, p 144

Naumann A, Stephan I, Noll M (2012) Int Biodeter Biodegr 75:28

Wu GF, Xu M (2014) Bioresources 9(3):4173

Karimi AN, Tajvidi M, Pourabbasi S (2007) Polym Compos 28(3):273

Gnatowski M, Ibach R, Leung M, Sun G (2015) Wood Mater Sci Eng 10:94

Machado JS, Santos S, Pinho FFS, Luís F, Alves A, Simões R, Rodrigues JC (2016) Mater Design 103:122

Toker H (2007) Doctoral Thesis, GU Institute of Science, Technology, Ankara

Tomak ED, Viitanen H, Yıldız UC, Hughes M (2011) J Mater Sci 46(3):608

Ramos AM, Caldeira Jorge F, Botelho C (2006) Holz Roh Werkst 64:445

Yalinkilic MK (2000) PhD Thesis Kyoto University, Kyoto, p 151

Freeman MH, McIntyre CR, Jackson D (2009) Proc Am Wood Prot Assoc 105:279

Acknowledgements

The authors would like to thank undergraduate student Ömür Ahmet Yazıcı for helping water immersion and decay testing in the Forest Industry Engineering Department, Bursa Technical University, Turkey.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cavdar, A.D., Tomak, E.D. & Mengeloglu, F. Long-Term Leaching Effect on Decay Resistance of Wood-Plastic Composites Treated with Boron Compounds. J Polym Environ 26, 756–764 (2018). https://doi.org/10.1007/s10924-017-0992-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-0992-7