Abstract

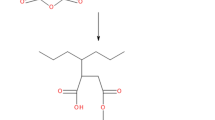

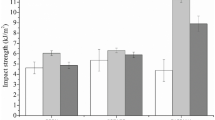

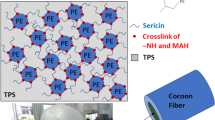

Different strategies to produce thermoplastic materials using starch and zein were studied, aiming to investigate their effect on the compatibility of starch and zein. Research strategies comprised the use of two different plasticizers for starch, two different compatibilizing agents, and two blending procedures. The plasticizers were mixtures of sorbitol and glycerol (SG) or urea and formamide (UF). UF and maleated starch (MS) were used as compatibilizing agents. The blending procedures included: (1) thermoextruding starch and zein as premixed powder materials (TP[Mix]) and (2) coextruding the biopolymers previously thermoplasticized with suitable plasticizers. As observed by the tensile tests, scanning electronic microscopy, and dynamic mechanical analysis, segregation of phases occurred at different extents in all the starch–zein blends. Materials made with MS through the TP[Mix] procedure presented the most severe phases segregation, while the materials made with UF showed higher compatibility between starch and zein. Fourier Transform Infrared Spectroscopy (FTIR) suggests that increased zein content leads to a lower molecular order, which was ascribed to diminished molecular entanglement. Thermogravimetric analysis and FTIR analysis showed that the chemical interaction between starch and zein occurred more extensively in slabs made with UF than those made with MS. In addition, foamability was evaluated for the selected materials using supercritical CO2. Neat thermoplasticized starch plasticized with UF and themoplasticized zein with polyethylene-glycol 400 showed good suitability to be foamed, producing foams with porosities above 85 %. Starch plasticized with SG and starch–zein blends yielded compact structures with low porosity values after foaming.

Similar content being viewed by others

Abbreviations

- UF:

-

Urea and formamide mixture at 2:1 (wt:wt) ratio

- SG:

-

Sorbitol and glycerol mixture at 1.4:1 (wt:wt) ratio

- MS:

-

Maleated starch

- MSG:

-

Mixture of native/maleated starch (50:50) and SG as plasticizer

- TPSUF :

-

Native starch thermoplasticized with UF

- TPSSG :

-

Native starch thermoplasticized with SG

- TPSMSG :

-

Thermoplasticized MSG

- TPZ:

-

Zein thermoplasticized with PEG400

- Mix[TP]:

-

Mixing thermoplasticized biopolymers through thermoextrusion

- TP[Mix]:

-

Thermoplasticizing powder compositions of biopolymers and plasticizers

References

Hablot E, Dewasthale S, Zhao Y, Zhiguan Y, Shi X, Graiver D, Narayan R (2013) Eur Polym J 49:873–881

Xie F, Halley PJ, Avérous L (2012) Prog Polym Sci 37:595–623

Zullo R, Iannace S (2009) Carbohydr Polym 77:376–383

Habeych E, van der Goot AJ, Boom R (2009) Chem Eng Sci 64:3516–3524

Lim S, Jane J (1994) J Environ Polym Degrad 2:111–120

Spence KE, Jane J, Pometto AL (1995) J Environ Polym Degrad 3:69–74

Chanvrier H, Colonna P, Della Valle G, Lourdin D (2005) Carbohyd Polym 59:109–119

Corradini E, Carvalho AJF, Curvelo AAS, Agnelli JAM, Mattoso LHC (2007) Mater Res 10:227–231

Habeych E, Dekkers B, van der Goot AJ, Boom R (2008) Chem Eng Sci 63:5229–5238

Zeng M, Huang Y, Lu L, Fan L, Lourdin D (2011) Carbohydr Polym 84:323–328

Chanvrier H, Della Valle G, Lourdin D (2006) Carbohydr Polym 65:346–356

Corradini E, Souto de Medeiros E, Carvalho AJF, Curvelo AAS, Mattoso LHC LHC (2006) J Appl Polym Sci 101:4133–4139

Leroy E, Jacquet P, Coativy G, Reguerre AL, Lourdin D (2012) Carbohydr Polym 89:955–963

Krogars K, Heinämäki J, Karjalainen M, Niskanen A, Leskelä M, Yliruusi J (2003) Int J Pharm 251:205–208

Di Maio E, Mali R, Iannace S (2010) J Polym Environ 18:626–633

Murúa-Pagola B, Beristain-Guevara CI, Martínez-Bustos F (2009) J Food Eng 91:380–386

Bulnes-Abundis D, Alvarez MM (2013) AIChE J 59:3092–3108

Sánchez Cervantes M, Lacombe J, Muzzio FJ, Álvarez MM (2006) Chem Eng Sci 61:8075–8084

Marrazzo C, Di Maio E, Iannace S (2007) J Cell Plast 43:123–133

Oliviero M, Verdolotti L, Di Maio E, Aurilia M, Iannace S (2011) J Agric Food Chem 59:10062–10070

Gaina C, Ursache O, Gaina V, Buruiana E, Ionita D (2012) Express Polym Lett 6:129–141

Huang M, Yu J, Ma X (2006) Carbohydr Polym 63:393–399

Lourdin D, Bizot H, Colonna P (1997) J Appl Polym Sci 63:1047–1053

Wu Q, Yoshino T, Sakabe H, Zhang H, Isobe S (2003) Polymer 44:3909–3919

Ma XF, Yu JG, Wan JJ (2006) Carbohyd Polym 64:267–273

Salerno A, Oliviero M, Di Maio E, Netti PA, Rofani C, Colosimo A, Guida V, Dallapiccola B, Palma P, Procaccini E, Berardi AC, Velardi F, Teti A, Iannace S (2010) J Mater Sci Mater Med 21:2569–2581

Verbeek CJR, van den Berg LE (2010) Macromol Mater Eng 295:10–21

Oliviero M, Di Maio E, Iannace S (2010) J Appl Polym Sci 115:277–287

Shi R, Zhang Z, Liu Q, Han Y, Zhang L, Chen D, Tian W (2007) Carbohydr Polym 69:748–755

Raquez JM, Nabar Y, Srinivasan M, Shin BY, Narayan R, Dubois P (2008) Carbohydr Polym 74:159–169

Tay SH, Pang SC, Chin SF (2012) Carbohydr Polym 88:1195–1200

Furukawa T, Sato H, Murakami R, Zhang J, Noda I, Ochiai S, Ozaki Y (2006) Polymer 47:3132–3140

Liu H, Adhikari R, Guo Q, Adhikari B (2013) J Food Eng 116:588–597

Van Soest JJG, Tournois H, de Wit D, Vliegenthart JFG (1995) Carbohydr Res 279:201–214

Sevenou O, Hill S, Farhat I, Mitchell J (2002) Int J Biol Macromol 31:79–85

Van Soest JJG, de Wit D, Tournois H, Vliegenthart JFG (1994) Starch 46:453–457

Salerno A, Oliviero M, Di Maio E, Iannace S (2007) Int Polym Proc 22:480–488

Acknowledgments

We gratefully acknowledge the financial support of Tecnológico de Monterrey through the seed fund CAT-121 and CDB-181 (Centro de Biotecnologia FEMSA, Tecnologico de Monterrey, Monterrey, Nuevo Leon, Mexico). CONACyT (Mexico) provided doctoral scholarship 45964 to GTdeS. We are grateful to Massimo Lombardo (Department of Materials and Production Engineering, University of Naples Federico II, Naples, Italy), Cristina del Barone (Laboratorio LaMest, CNR, Naples, Italy), Fabio Docimo, and Maria Rosaria Marcedula (Istituto per i Materiali Compositi e Biomedici, CNR, Naples, Italy) for the technical support provided for producing and studying the materials addressed in this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Trujillo-de Santiago, G., Rojas-de Gante, C., García-Lara, S. et al. Strategies to Produce Thermoplastic Starch–Zein Blends: Effect on Compatibilization. J Polym Environ 22, 508–524 (2014). https://doi.org/10.1007/s10924-014-0685-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-014-0685-4