Abstract

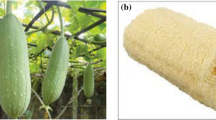

Okra (Lady’s finger, Abelmoschus esculentus) fibres were introduced in a poly(lactic) acid (PLA) polymer matrix as short fibres (5–10 mm), in amounts variable between 10 and 30 %wt. For this purpose, both untreated and alkali treated okra fibres were used. The obtained composites, in view of the envisaged application for sustainable packaging purposes, has been tested morphologically, mechanically and subjected to chemical characterisation, while the biodegradation profile has been studied. The introduction of fibres in the polymer matrix always resulted in a higher stiffness of the obtained composite. The addition of okra fibre to PLA results in an increased ability of the PLA matrix to crystallize due to the nucleation effect of the okra fibre, and this effect was more evident in the composites produced with alkali treated fibres. The biodegradation process was accelerated by the addition of higher contents of fibres into the composites due to preferential degradation of the fibres themselves: this effect was increased when composite fibres are alkali-treated.

Similar content being viewed by others

References

De Rosa IM, Kenny JM, Puglia D, Santulli C, Sarasini F (2010) Compos Sci Technol 70(1):116

Srinivasababu N, Mohan Rao KM, Suresh Kumar J (2009) Int. J Eng 3(4):403

Md Moniruzzaman, Mohd Maniruzzaman, Gafur MA, Santulli C (2009) J Biobased Mater Bio 3(3):286

De Rosa IM, Kenny JM, Mohd Maniruzzaman, Moniruzzaman M, Monti M, Puglia D, Santulli C, Sarasini F (2011) Compos. Sci Technol 71(2):246

Fortunati E, Puglia D, Monti M, Santulli C, Maniruzzaman M, Kenny JM (2012) J Appl Polym Sci. doi:10.1002/app.38524

Serizawa S, Inoue K, Iji M (2006) J Appl Polym Sci 100:618

Huda MS, Drzal LT, Mohanty AK, Misra M (2008) Compos Sci Technol 68:424

Lee BH, Kim HS, Lee S, Kim HJ, Dorgan JR (2009) Compos Sci Technol 69:2573

Plackett D (2004) J Polym Environ 12:131

Khondker OA, Ishiaku US, Nakai A, Hamada H (2006) Compos A 37:2274

Graupner N, Herrmann AS, Müssig J (2009) Compos A 40:810

Hu R, Lim JK (2007) J Compos Mater 41:1655

Masirek R, Kulinski Z, Chionna D, Piorkowska E, Pracella M (2007) J Appl Polym Sci 105:255

Bodros E, Pillin I, Montrelay N, Baley C (2007) Compos Sci Technol 67:462

Oksman K, Skrifvars M, Selin JF (2003) Compos Sci Technol 63:1317

Bax B, Müssig J (2008) Compos Sci Technol 68:1601

De Rosa IM, Iannoni A, Kenny JM, Puglia D, Santulli C, Sarasini F, Terenzi A (2011) Polym Compos 32(9):1362

Fischer H, Werwein E, Graupner N (2012) J Compos Mater 46:3077

Kirwan K, Johnson RM, Jacobs DK, Smith GF, Shepherd L, Tucker N (2007) Ind Crop Prod 26(1):14

López JP, Vilaseca F, Méndez JA, Franco E, Boufi S, Belhassen R, Mutjé P, Carvalho AJF, Curvelo AAS, V CIADICYP Conference, October 2008, Guadalajara, Jalisco, México

Juntuek P, Ruksakulpiwat C, Chumsamrong X, Ruksakulpiwat Y (2011) Adv Mater Res 410:55

Fortunati E, Puglia D, Santulli C, Sarasini F, Kenny JM (2012) J Appl Polym Sci 125:E562–E572. doi:10.1002/app.36839

Chattopadhyay H, Sarkar PB (1946) Proc Natl Inst Sci India 12:23

Alvarez VA, Vasquez A (2006) Compos A 37(10):1672

Arifuzzaman Khan GM, Shaheruzzaman Md, Rahman MH, Abdur Razzaque SM, Sakinul Islam Md, Shamsul Alam Md (2009) Fibers and Polym 10(1):65

Liu W, Mohanty AK, Drzal LT, Askel P, Misra M (2004) J Mater Sci 39(3):1051

Paiva MC, Ammar I, Campos AR, Cheikh RB, Cunha AM (2007) Compos Sci Technol 67(6):1132

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Cellulose 15:149

Petrova SN, Volkova IY, Zakharov AG (2004) Fibre Chem 36(6):393

Sgriccia N, Hawley MC, Misra M (2008) Compos A 39(10):1632

Pastorova I, Boon JJ, Arisz PW, Boon JJ (1994) Carbohydr Res 262:27

Mwaikambo LY, Ansell MP (2002) J Appl Polym Sci 84(12):2222

Liu D, Han G, Huang JH, Zhang Y (2009) Carbohydr Polym 75(1):39

Sun RC, Tomkinson J, Ma PL, Liang SF (2000) Carbohydr Polym 42:111

Johnson Ford EN, Mendon SK, Thames SF, Rawlins JW (2010) J Eng Fiber Fabr 5(1):10

Thygesen A, Oddershede J, Lilholt H, Thomsen AB, Stahl K (2005) Cellulose 12(6):563

Xu W, Reddy N, Yang Y (2009) Carbohydr Polym 76(4):521

Tripp VW, Conrad CM (1972) In Instrumental Analysis of Cotton Cellulose and Modified Cotton Cellulose. O’Connor RT (ed) Marcell Dekker Inc, New York p 339

Hori R, Wada M (2006) Cellulose 13:281

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Biotechnol Biofuels 3:10

Mathew AP, Oksmanand K, Sain M (2005) J Appl Polym Sci 97:2014

Islam MS, Pickering KL, Foreman NJ (2010) Compos A 41:596

Pluta M, Galeski A, Alexandre M, Paul MA, Dubois P (2002) J Appl Polym Sci 86:1497

Fortunati E, Armentano I, Iannoni A, Kenny JM (2010) Polym Degrad Stab 95:2200

Fortunati E, Armentano I, Zhou Q, Iannoni A, Saino E, Visai L, Berglund LA, Kenny JM (2012) Carbohydr Polym 87:1596

Richards E, Rizvi R, Chow A, Naguib H (2008) J Polym Environ 16:258

Joseph PV, Joseph K, Thomas S, Pillai CKS, Prasad VS, Groeninckx G, Sarkissova M (2003) Compos A 34:253

Gattin R, Copinet A, Bertrand C, Couturier Y (2002) Int Biodeterior Biodegrad 50:25

Li S, Girard A, Garreau H, Vert M (2001) Polym Degrad Stab 71:61

Fortunati E, Armentano I, Iannoni A, Barbale M, Zaccheo S, Kenny JM (2011) J Appl Polym Sci 124(1):87

Scott G (1997) Trends Polym Sci 5:361

Teramoto N, Urata K, Ozawa K, Shibata M (2004) Polym Degrad Stab 86:401

Iovino R, Zullo R, Rao MA, Cassar L, Gianfreda L (2007) Polym Degrad Stab 93:147

Fukushima K, Abbate C, Tabuani D, Gennari M, Camino G (2009) Polym Degrad Stab 94:1646

ISO20200—Determination of the degree of disintegration of plastic materials under simulated composting conditions in a laboratory-scale test

Kumar R, Yakubu MK, Anandjiwala RD (2010) eXPRESS. Polym Lett 14(7):423

Acknowledgments

The authors gratefully acknowledge the financial support from INSTM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fortunati, E., Puglia, D., Monti, M. et al. Okra (Abelmoschus esculentus) Fibre Based PLA Composites: Mechanical Behaviour and Biodegradation. J Polym Environ 21, 726–737 (2013). https://doi.org/10.1007/s10924-013-0571-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-013-0571-5