Abstract

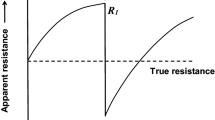

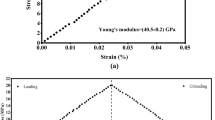

This work provides the first report of the effect of the dielectric behavior on the conduction behavior of solder. The lead-free solder studied contains 96 wt% tin and 4 wt% silver. The electric polarization stems from the interaction of the valence electrons with the atoms. The fraction of valence electrons that participate in the initial polarization is of the order of 10–9. The injected electrons play a minor role compared to the valence electrons of the solder in the polarization. The efficiency of the injected electrons in promoting the polarization decreases with the increasing number of injected electrons. Due to the polarization under a constant applied DC current (30–100 mA), the apparent electrical resistivity increases beyond the true resistivity. The rate of apparent resistivity increase diminishes as the time of current application increases. The fractional increase is 0.10% at 130 s of 100-mA current application. The higher is the current, the greater are the degree and rate of polarization at a given time. The current effect saturates above ~ 90 mA. Upon reversal of the polarity of the applied current, depolarization (followed by reverse polarization) occurs. The rates of depolarization and reverse polarization, as indicated by the rate of apparent resistivity increase, increase with increasing current. These rates decrease with increasing time. At the same current and respective time, the rates of polarization and depolarization are essentially equal, but the rate of reverse polarization is much below that of the initial polarization. Furthermore, the nearly saturated degree of reverse polarization is much below that of the initial polarization. This indicates a partially irreversible effect of the initial polarization that hinders the reverse polarization.

Similar content being viewed by others

Data availability

Data and material are available by contacting the corresponding author.

Change history

21 April 2021

A Correction to this paper has been published: https://doi.org/10.1007/s10854-021-05937-z

References

W.J. Plumbridge, Solders in electronics. J. Mater. Sci. 31(10), 2501–2514 (1996)

X. Xi, D.D.L. Chung, Piezoresistivity and piezoelectricity, dielectricity discovered in solder. J. Mater. Sci. 30(5), 4462–4472 (2019)

X. Xi, D.D.L. Chung, Role of grain boundaries in the dielectric behavior of graphite. Carbon 173, 1003–1019 (2021)

X. Xi, D.D.L. Chung, Electret, piezoelectret, dielectricity and piezoresistivity discovered in exfoliated-graphite-based flexible graphite, with applications in mechanical sensing and electric powering. Carbon 150, 513–548 (2019)

X. Xi, D.D.L. Chung, Colossal electric permittivity discovered in polyacrylonitrile (PAN) based carbon fiber, with comparison of PAN-based and pitch-based carbon fibers. Carbon 145, 734–739 (2019)

X. Xi, D.D.L. Chung, Effect of nickel coating on the stress-dependent electric permittivity, piezoelectricity and piezoresistivity of carbon fiber, with relevance to stress self-sensing. Carbon 145, 401–410 (2019)

A.A. Eddib, D.D.L. Chung, Electric permittivity of carbon fiber. Carbon 143, 475–480 (2019)

X. Xi, D.D.L. Chung, Electret, piezoelectret and piezoresistivity discovered in steels, with application to structural self-sensing and structural self-powering. Smart Mater. Struct. 28(7), 075028 (2019)

X. Xi, D.D.L. Chung, Piezoresistivity and piezoelectricity discovered in aluminum, with relevance to structural self-sensing. Sens. Actuators A 289, 144–156 (2019)

G.A. Rinne, Issues in accelerated electromigration of solder bumps. Microelectron. Reliab. 43(12), 1975–1980 (2003)

H. Gan, W.J. Choi, G. Xu, K.N. Tu, Electromigration in solder joints and solder lines. JOM 54(6), 34–37 (2002)

Q.T. Huynh, C.Y. Liu, C. Chen, K.N. Tu, Electromigration in eutectic SnPb solder lines. J. Appl. Phys. 89(8), 4332–4335 (2001)

Y. Hung, C. Chen, Electromigration of Sn-9wt.%Zn solder. J. Electronic Mater. 37(6), 887–893 (2008)

J. Nah, J.H. Kim, H.M. Lee, K. Paik, Electromigration in flip chip solder bump of 97Pb-3Sn/37Pb-63Sn combination structure. Acta Mater. 52(1), 129–136 (2004)

Y.H. Lin, C.M. Tsai, Y.C. Hu, Y.L. Lin, C.R. Kao, Electromigration-induced failure in flip-chip solder joints. J. Electronic Mater. 34(1), 27–33 (2005)

J.R. Huang, C.M. Tsai, Y.W. Lin, C.R. Kao, Pronounced electromigration of Cu in molten Sn-based solders. J. Mater. Res. 23(1), 250–257 (2008)

X. Xi, D.D.L. Chung, Dynamics of the electric polarization and depolarization of graphite. Carbon 172, 83–95 (2021)

M. Abtew, G. Selvaduray, Lead-free solders in microelectronics. Mater. Sci. Eng. R 27(5–6), 95–141 (2000)

C.M. Miller, I.E. Anderson, J.F. Smith, A viable tin-lead solder substitute: Sn-Ag-Cu. J. Electronic Mater. 23(7), 595–601 (1994)

J. Yoon, J. Back, S. Jung, Comparative study of ENEPIG and thin ENEPIG as surface finishes for SAC305 solder joints. J. Mater. Sci.: Mater. Electron. 29(6), 4724–4731 (2018)

M. Reid, F. Punch, M. Collins, C. Ryan, Effect of Ag content on the microstructure of Sn-Ag-Cu based solder alloys. Solder. Surface Mount Technol. 20(4), 3–8 (2008)

P.G. Kim, K.N. Tu, Fast dissolution and soldering reactions on Au foils. Mater. Chem. Phys. 53(2), 165–171 (1998)

G. Chen, J. Ma, The mechanical behavior of Sn-Ag4 solder joints subjected to thermal cycling. Chin. J. Electron. 13(3), 416–418 (2004)

W. Yang, R.W. Messler Jr, L.E. Felton, Microstructure evolution of eutectic Sn-Ag solder joints. J. Electron. Mater. 23(8), 765–772 (1994)

W. Yang, D.D.L. Chung, Effect of temperature on the electrical conduction and dielectric behavior of solder (in press)

D.D.L. Chung, X. Xi, Electric poling of carbon fiber with and without nickel coating, Carbon 162, 25–35 (2020)

https://www.metallurgy.nist.gov/phase/solder/agsn-w.jpg (as viewed on Dec. 27, 2020)

Funding

This work was supported in part by New York State Department of Economic Development via New York State Center of Excellence for Materials Informatics.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

Yang declares that he has no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. Chung declares that she has no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, W., Chung, D.D.L. Electric polarization and depolarization of solder, and their effects on electrical conduction. J Mater Sci: Mater Electron 32, 6214–6227 (2021). https://doi.org/10.1007/s10854-021-05337-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05337-3