Abstract

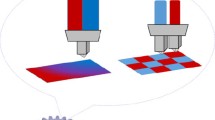

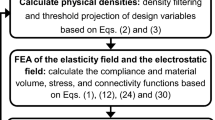

As multi-material additive manufacturing technologies mature, a new opportunity for materials science and engineering emerges between the scale of the microstructure and the scale of an engineering component. Here we explore the problem of “mesostructure optimization,” the computational identification of preferred point-to-point distributions of material structure and properties. We illustrate the opportunity with two simple example problems for 1D and 2D mesostructure optimization, respectively, namely (1) a functionally graded cylinder that is computationally optimized to redistribute the Hertzian contact stress fields and (2) a thin plate made of digital materials computationally designed to simultaneously maximize bending resistance and minimize total weight. The mechanical performance of materials in these two problems is significantly improved as compared to any monolithic-material counterpart, including a topology-optimized monolith in case (2). These results point to new opportunities for multi-objective performance enhancement in materials.

Similar content being viewed by others

References

Bourell DL, Leu MC, Rosen DW (2009) Roadmap for additive manufacturing: identifying the future of freeform processing. The University of Texas, Austin, Texas

Gebhardt A (2012) Understanding additive manufacturing: rapid prototyping, rapid tooling, rapid manufacturing. Hanser Publications, Cincinnati

Gibson I, Rosen DW, Stucker B (2010) Additive manufacturing technologies, SpringerLink (Online service). Springer, New York

Hopkinson N, Hague RJM, Dickens PM (2006) Rapid manufacturing: an industrial revolution for the digital age. Wiley, Chichester

Compton BG, Lewis JA (2014) 3D printing of lightweight cellular composites. Adv Mater 26:5930–5935

Bauer J, Hengsbach S, Tesari I, Schwaiger R, Kraft O (2014) High-strength cellular ceramic composites with 3D microarchitecture. Proc Natl Acad Sci USA 111:2453–2458

Smay JE, Gratson GM, Shepherd RF, Cesarano J, Lewis JA (2002) Directed colloidal assembly of 3D periodic structures. Adv Mater 14:1279–1283

Hofmann DC, Roberts S, Otis R, Kolodziejska J, Dillon RP, Suh JO, Shapiro AA, Liu ZK, Borgonia JP (2014) Developing gradient metal alloys through radial deposition additive manufacturing. Sci Rep 4:5357

Banerjee R, Collins PC, Bhattacharyya D, Banerjee S, Fraser HL (2003) Microstructural evolution in laser deposited compositionally graded α/β titanium-vanadium alloys. Acta Mater 51:3277–3292

Oxman N, Keating S, Tsai E (2011) Functionally graded rapid prototyping, innovative developments in virtual and physical prototyping. In: Proceedings of the 5th international conference on advanced research in virtual and rapid prototyping, CRC Press, Taylor & Francis

Bendsøe MP, Sigmund O (2003) Topology, optimization: theory, methods, and applications. Springer, Berlin

Rozvany GIN (1997) Topology optimization in structural mechanics. Springer, Wien

Bruns TE, Tortorelli DA (2001) Topology optimization of non-linear elastic structures and compliant mechanisms. Comput Methods Appl Mech Eng 190:3443–3459

Bureerat S, Limtragool J (2006) Performance enhancement of evolutionary search for structural topology optimisation. Finite Elem Anal Des 42:547–566

Lamberti L (2008) An efficient simulated annealing algorithm for design optimization of truss structures. Comput Struct 86:1936–1953

Moita JMS, Correia VMF, Martins PG, Soares CMM, Soares CAM (2006) Optimal design in vibration control of adaptive structures using a simulated annealing algorithm. Compos Struct 75:79–87

Sigmund O (1997) On the design of compliant mechanisms using topology optimization. Mech Struct Mach 25:493–524

Suzuki K, Kikuchi N (1991) A homogenization method for shape and topology optimization. Comput Methods Appl Mech Eng 93:291–318

Rozvany GIN (2009) A critical review of established methods of structural topology optimization. Struct Multidiscip Optim 37:217–237

Adams BL, Kalidindi S, Fullwood DT (2013) Microstructure sensitive design for performance optimization. Butterworth-Heinemann, Waltham

Torquato S (2010) Optimal design of heterogeneous materials. Annu Rev Mater Res 40:101–129

Torquato S (2002) Random heterogeneous materials: microstructure and macroscopic properties. Springer, New York

Johnson OK, Schuh CA (2013) The uncorrelated triple junction distribution function: towards grain boundary network design. Acta Mater 61:2863–2873

Cross SR, Woollam R, Shademan S, Schuh CA (2013) Computational design and optimization of multilayered and functionally graded corrosion coatings. Corros Sci 77:297–307

Suresh S, Mortensen A (1998) Fundamentals of functionally graded materials: processing and thermomechanical behaviour of graded metals and metal–ceramic composites. IOM Communications Ltd, London

Mortensen A, Suresh S (1995) Functionally graded metals and metal–ceramic composites: part 1 processing. Int Mater Rev 40:239–265

Suresh S, Mortensen A (1997) Functionally graded metals and metal–ceramic composites: part 2 thermomechanical behaviour. Int Mater Rev 42:85–116

Johnson KL (1985) Contact mechanics. Cambridge University Press, Cambridge

Ashby MF (2005) Materials selection in mechanical design, 3rd edn. Butterworth-Heinemann, Amsterdam

Yang X-S (2014) Nature-inspired optimization algorithms. Elsevier, London

Seidel R et al (2016) Ultrastructural and developmental features of the tessellated endoskeleton of elasmobranchs (sharks and rays). J Anat 229:681–702

Gibson LJ (2012) The hierarchical structure and mechanics of plant materials. J R Soc Interface 9:2749–2766

Dixon PG, Gibson LJ (2014) The structure and mechanics of Moso bamboo material. J R Soc Interface 11:20140321

Balla VK et al (2007) Compositionally graded yttria-stabilized zirconia coating on stainless steel using laser engineered net shaping (LENS). Scripta Mater 57:861–864

Balla VK et al (2009) Fabrication of compositionally and structurally graded Ti–TiO2 structures using laser engineered net shaping (LENS). Acta Biomater 5:1831–1837

Wilson J, Shin YC (2012) Microstructure and wear properties of laser-deposited functionally graded Inconel 690 reinforced with TiC. Surf Coat Technol 207:517–522

Vaezi M et al (2013) Multiple material additive manufacturing—part 1: a review. Virtual Phys Prototyp 8:19–50

Tammas-Williams S, Todd I (2016) Design for additive manufacturing with site-specific properties in metals and alloys. Scripta Materialia. doi:10.1016/j.scriptamat.2016.10.030

Liu W, DuPont JN (2003) Fabrication of functionally graded TiC/Ti composites by laser engineered net shaping. Scripta Mater 48:1337–1342

Stratasy website. http://www.stratasys.com/materials/polyjet/digital-materials

Doubrovski EL et al (2015) Voxel-based fabrication through material property mapping: a design method for bitmap printing. Comput Aided Des 60:3–13

Suresh S (2001) Graded materials for resistance to contact deformation and damage. Science 292:2447–2451

Sigmund O (2001) Design of multiphysics actuators using topology optimization—part I: one-material structures. Comput Methods Appl Mech Eng 190:6577–6604

Acknowledgements

This work enjoyed support from the US National Science Foundation, under contract No. CMMI-1332789.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yu, H.Z., Cross, S.R. & Schuh, C.A. Mesostructure optimization in multi-material additive manufacturing: a theoretical perspective. J Mater Sci 52, 4288–4298 (2017). https://doi.org/10.1007/s10853-017-0753-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0753-y