Abstract

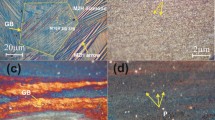

Prior studies on shape memory alloys have identified size effects on the superelastic, i.e., stress-induced, hysteresis of martensitic transformations. However, literature on thermally induced transformations and size effects upon stored elastic energy is rather limited. In this work, a complementary sample size effect on the stored elastic energy of the transformation, and its effect on variant selection, is elaborated. Shape memory alloy microwires of a CuAlMnNi alloy are drawn with diameters varying between 45 and 255 μm and processed to obtain bamboo grain structures, where the grain boundaries lay almost perpendicular to the wire axis. Calorimetric and thermomechanical analyses of the microwires establish a decreasing contribution of stored elastic energy to the free energy of martensitic transformation as the wire diameter is reduced. This in turn affects the transformation ranges and macroscopic strain generated in constrained thermal cycling. The effect is shown to be associated with a decrease in number of interacting martensite variants as well as relaxation on free surfaces. The presented results indicate that thermal actuation of lightly biased SMA wires is enhanced in finer wires.

Similar content being viewed by others

References

Chen Y, Schuh CA (2011) Size effects in shape memory alloy microwires. Acta Mater 59:537–553. doi:10.1016/j.actamat.2010.09.057

Ozdemir N, Karaman I, Mara NA et al (2012) Size effects in the superelastic response of Ni54Fe19Ga27 shape memory alloy pillars with a two stage martensitic transformation. Acta Mater 60:5670–5685. doi:10.1016/j.actamat.2012.06.035

Ueland SM, Schuh CA (2012) Superelasticity and fatigue in oligocrystalline shape memory alloy microwires. Acta Mater 60:282–292. doi:10.1016/j.actamat.2011.09.054

Chen Y, Zhang X, Dunand DC, Schuh CA (2009) Shape memory and superelasticity in polycrystalline Cu–Al–Ni microwires. Appl Phys Lett 95:171906. doi:10.1063/1.3257372

Ueland SM, Schuh CA (2013) Transition from many domain to single domain martensite morphology in small-scale shape memory alloys. Acta Mater 61:5618–5625. doi:10.1016/j.actamat.2013.06.003

Dunand DC, Müllner P (2011) Size effects on magnetic actuation in Ni-Mn-Ga shape-memory alloys. Adv Mater 23:216–232

Sutou Y, Omori T, Yamauchi K et al (2005) Effect of grain size and texture on pseudoelasticity in Cu–Al–Mn-based shape memory wire. Acta Mater 53:4121–4133. doi:10.1016/j.actamat.2005.05.013

San Juan J, Nó ML, Schuh CA (2008) Superelasticity and shape memory in micro- and nanometer-scale pillars. Adv Mater 20:272–278. doi:10.1002/adma.200701527

Waitz T, Kazykhanov V, Karnthaler HP (2004) Martensitic phase transformations in nanocrystalline NiTi studied by TEM. Acta Mater 52:137–147. doi:10.1016/j.actamat.2003.08.036

Waitz T, Antretter T, Fischer FD et al (2007) Size effects on the martensitic phase transformation of NiTi nanograins. J Mech Phys Solids 55:419–444. doi:10.1016/j.jmps.2006.06.006

Lovey FC, Chandrasekaran M (1982) Diffraction effects in β Cu-Zn and β-Cu-Zn-Al surface martensite transformation and microstructure. Le J Phys Colloq 43:C4–583. doi:10.1051/jphyscol:1982491

Ortin J, Planes A (1988) Thermodynamic analysis of thermal measurements in thermoelastic martensitic transformations. Acta Metall 36:1873–1889

Otsuka K, Wayman C (1999) Shape memory materials. Cambridge University Press, London

Ortĺn J, Delaey L (2002) Hysteresis in shape-memory alloys. Int J Non Linear Mech 37:1275–1281

Wada K, Liu Y (2008) On the two-way shape memory behavior in NiTi alloy—an experimental analysis. Acta Mater 56:3266–3277. doi:10.1016/j.actamat.2008.03.005

Hamilton R, Sehitoglu H, Chumlyakov Y, Maier H (2004) Stress dependence of the hysteresis in single crystal NiTi alloys. Acta Mater 52:3383–3402. doi:10.1016/j.actamat.2004.03.038

Liu Y, Favier D, Orgeas L (2004) Mechanistic simulation of thermomechanical behaviour of thermoelastic martensitic transformations in polycrystalline shape memory alloys. J Phys 115:37–45. doi:10.1051/jp4

Lovey FC, Torra V (1999) Shape memory in Cu-based alloys : phenomenological behavior at the mesoscale level and interaction of martensitic transformation with structural defects in Cu-Zn-Al. Prog Mater Sci 44:189–289

Ma J, Karaman I, Noebe RD (2010) High temperature shape memory alloys. Int Mater Rev 55:257–315. doi:10.1179/095066010X12646898728363

Sugimoto K, Kamei K, Nakaniwa M (1990) Cu-Al-Ni-Mn: a new shape memory alloy for high temperature applications. Butterworth-Heinemann, Oxford

Wu M, Semiatin S, Schetky L (1994) Fabrication of a Cu-Al-Ni-Mn shape memory alloy. Mater Charact 246:343–348

Morris MA (1992) High temperature properties of ductile Cu-Al-Ni shape memory alloys with boron additions. Acta Metall Mater 40:1573–1586

Segui C, Cesari E (1995) Ordering and stabilization in quenched CuAlNiMnB alloys. J Mater Sci 30:5770–5776. doi:10.1007/BF00356719

Chen L, Dunne D, Kennon N (1997) Determination of the parent grain orientation and habit plane normals for β′ 1 martensite in a Cu–Al–Ni–Mn shape memory alloy. J Mater Sci 2:3769–3773. doi:10.1023/A:1018671506278

Sutou Y, Omori T, Kainuma R et al (2002) Enhancement of Superelasticity in Cu-Al-Mn-Ni shape- memory alloys by texture control. Metall Mater Trans A 33:2817–2824

Morris MA, Lipe T (1994) Microstructural influence of Mn additions on thermoelastic and pseudoelastic properties of Cu-Al-Ni alloys. Acta Metall Mater 42:1583–1594. doi:10.1016/0956-7151(94)90368-9

Ratchev P, Van Humbeeck J, Delaey L (1993) On the formation of 2H stacking sequence in 18R martensite plates in a precipitate containing Cu-Al-Ni-Ti-Mn alloy. Acta Metall Mater 41:2441–2449

Omori T, Koeda N, Sutou Y et al (2007) Superplasticity of Cu-Al-Mn-Ni shape memory alloy. Mater Trans 48:2914–2918. doi:10.2320/matertrans.D-MRA2007879

Patoor E, Supe Z, Ge D et al (1995) Micromechanical modelling of the superelastic behavior. Le J Phys. 5:C2

Bhattacharya K (2003) Microstructure of Martensite: why it forms and how it gives rise to the shape-memory effect. Oxford University Press, Oxford

Patoor E, Lagoudas DC, Entchev PB et al (2006) Shape memory alloys, Part I: general properties and modeling of single crystals. Mech Mater 38:391–429. doi:10.1016/j.mechmat.2005.05.027

Jung Y, Papadopoulos P, Ritchie RO (2004) Constitutive modelling and numerical simulation of multivariant phase transformation in superelastic shape-memory alloys. Int J Numer Methods Eng 60:429–460. doi:10.1002/nme.940

Thamburaja P, Anand L (2001) Polycrystalline shape-memory materials: effect of crystallographic texture. J Mech Phys Solids 49:709–737. doi:10.1016/S0022-5096(00)00061-2

Gao X, Brinson L (2002) A simplified multivariant SMA model based on invariant plane nature of martensitic transformation. J Intell Mater Syst Struct 13:795–810. doi:10.1177/104538902032786

Wollants P, Roos JR, Delaey L (1993) Thermally- and stress-induced thermoelastic martensitic transformations in the reference frame of equilibrium thermodynamics. Prog Mater Sci 37:227–288. doi:10.1016/0079-6425(93)90005-6

San Juan J, Nó ML, Schuh CA (2009) Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat Nanotechnol 4:415–419. doi:10.1038/nnano.2009.142

Salzbrenner R, Cohen M (1979) On the thermodynamics of thermoelastic martensitic transformations. Acta Metall 27:739–748

Romero R, Pelegrina JL (2003) Change of entropy in the martensitic transformation and its dependence in Cu-based shape memory alloys. Mater Sci Eng A 354:243–250. doi:10.1016/S0921-5093(03)00013-3

Saburi T, Wayman C (1979) Crystallographic similarities in shape memory martensites. Acta Metall 27:979–995. doi:10.1016/0001-6160(79)90186-X

Acknowledgements

This work was supported by the U.S. Army Research Laboratory and the U.S. Army Research Office through the Institute for Soldier Nanotechnologies, under contract number W911NF-13-D-0001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tuncer, N., Qiao, L., Radovitzky, R. et al. Thermally induced martensitic transformations in Cu-based shape memory alloy microwires. J Mater Sci 50, 7473–7487 (2015). https://doi.org/10.1007/s10853-015-9306-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9306-4