Abstract

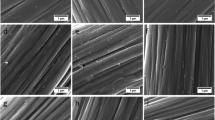

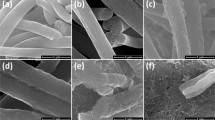

A unique consideration is intended, concerning the creation of functional groups during the production of carbon fibres from polyacrylonitrile, i.e. oxidation/stabilization, carbonization/pyrolysis and electrochemical modification processes and their role for applications. Acrylic fibres of homopolymer PAN are subjected to thermo-oxidative treatment following a four-stage or a two-stage isothermal programme, and the resulting oxidized fibres are pyrolyzed up to 1000 °C for 30 min or they are flash-pyrolyzed at 1000 °C for 5 min, and the shrinkage and weight loss are determined. According to FTIR spectra, two indices were expressed to follow the dehydrogenations and cyclizations (nitrile groups) and the band intensity of carbonyl groups to follow the oxidation. The carbon fibres produced from the four-stage oxidation were examined using SEM/EDS. Based on SEM/EDS analysis, an oxygen content of approx. 8.7 at.% in the fibres is needed for the stabilization of the fibres during the oxidation by a four-stage treatment up to 300 °C. These carbon fibres were electrochemically modified by Cyclic Voltammetry in narrow and wide potential regions, using aqueous H2SO4. The electrochemical treatment of carbon fibres in the wide region leads to the introduction of an additional amount of oxygen of about 5 at.%, exhibiting also acidic and basic groups in adequate amount. The formation of oxygenous groups on carbon fibres during the three processes is indirectly followed by their ability to adsorb methylene blue or alizarin yellow dyes, based on the concept of “acid–base interaction”. Considering a model of a graphitic monolayer of a basic square that includes 9 rings, the O atoms introduced in this segment were estimated. Carbon fibre applications depend on the amount and type of oxygenous groups that can be targeted by selecting proper treatment conditions.

Similar content being viewed by others

References

Gupta AK, Paliwal DK, Bajaj P (1991) Acrylic precursors for carbon fibers. JMS Rev Macromol Chem Phys C 31(1):1–89

Perepelkin KE (2002) Carbon fibres with specific physical and physicochemical properties based on hydrated cellulose and polyacrylonitrile precursors. A review. Fibre Chem 34:271–280

Liu J, Zhang WX (2005) Structural changes during the thermal stabilization of modified and original polyacrylonitrile precursors. Z J Appl Polym Sci 97:2047–2053

Rahaman MSA, Ismail AF, Mustafa A (2007) A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stabil 92:1421–1432

Yusof N, Ismail AF (2012) Post spinning and pyrolysis processes of polyacrylonitrile (PAN)-based carbon fiber and activated carbon fiber: a review. J Anal Appl Pyrol 93:1–13

Xue Y, Liu J, Liang J (2013) Correlative study of critical reactions in polyacrylonitrile based carbon fiber precursors during thermal-oxidative stabilization. J Polym Degrad Stabil 98:219–229

Williams G, Trask R, Bond I (2007) A self-healing carbon fibre reinforced polymer for aerospace applications. Composites Part A 38:1525–1532

Ko YG, Choi US, Kim JS, Park YS (2002) Novel synthesis and characterization of activated carbon fiber and dye adsorption modeling. Carbon 40:2661–2672

Antolini E (2009) Carbon supports for low-temperature fuel cell catalysts. Rev Appl Catal B-Environ 88:1–24

Huang X (2009) Fabrication and properties of carbon fibers. Rev Mater 2:2369–2403

Morgan P (2005) Carbon fiber and their composites. CRC Press, Taylor & Francis Group LCC, Brighton

Rebouillat S, Peng JCM, Donnet JB, Ryu SK (1998) Carbon fibers applications. In: Donnet JB, Wang TK, Peng JCM, Rebouillat S (eds) Carbon fibers, 3rd edn. Marcel Dekker Inc., New York

Soulis S, Simitzis J (2005) Thermomechanical behaviour of poly[acrylonitrile-co-(methyl acrylate)] fibres oxidatively treated at temperatures up to 180 °C. Polym Int 54:1474–1483

Xu B, Wang X, Lu Y (2006) Surface modification of polyacrylonitrile-based carbon fiber and its interaction with imide. Appl Surf Sci 253:2695–2701

Hansmann H (2003) ASM Handbook/extraction interfaces. Compendium composites: FB MVU: Werkstofftechnologien/Kunststofftechnik

Stein A, Wang Z, Fierke MA (2009) Functionalization of porous carbon materials with designed pore architecture. Adv Mater 21:265–293

Georgiou P, Walton J, Simitzis J (2010) Surface modification of pyrolyzed carbon fibres by cyclic voltammetry and their characterization with XPS and dye adsorption. Electrochim Acta 55:1207–1216

László K, Josepovits K, Tombácz E (2001) Analysis of active sites on synthetic carbon surfaces by various methods. Anal Sci 17:i1741–i1744

Yue ZR, Jiang W, Wang L, Gardner SD, Pittman CUJ (1999) Surface characterization of electrochemically oxidized carbon fibers. Carbon 37:1785–1796

Ramanathan T, Bismarck A, Schulz E, Subramanian K (2001) Investigation of the influence of surface-activated carbon fibres on debonding energy and frictional stress in polymer-matrix composites by the micro-indentation technique. Compos Sci Technol 61:2511–2518

Bismarck A, Kumru ME, Springer J, Simitzis J (1999) Surface properties of PAN-based carbon fibers tuned by anodic oxidation in different alkaline electrolyte systems. J Appl Surf Sci 143:45–55

Sharma M, Gao Mäder E, Sharma H, Wei LY, Bijwe J (2014) Carbon fiber surfaces and composite interphases. Compos Sci Technol 102:35–50

Zhang S, Chen S, Zhang Q, Li P, Yuan C (2008) Preparation and characterization of an ion exchanger based on semi-carbonized polyacrylonitrile fiber. React Funct Polym 68:891–898

Leyva-Ramos R, Berber-Mendoza MS, Salazar-Rabago J, Guerrero-Coronado RM, Mendoza-Barron J (2011) Adsorption of lead(II) from aqueous solution onto several types of activated carbon fibers. J Adsorption 17(3):515–526

Rrodriguez-Reinoso F (1998) The role of carbon materials in heterogeneous catalysis. Carbon 36(3):159–175

Jin J (2014) Shi Zq, Wang Cy. Electrochemical Performance of Electrospun carbon nanofibers as free-standing and binder-free anodes for Sodium-Ion and Lithium-Ion Batteries. Electrochim Acta 141:302–310

Pandolfo AG, Hollenkamp AF (2006) Carbon properties and their role in supercapacitors. Review. J Power Sources 157:11–27

Zhang LL, Zhao XS (2009) Carbon-based materials as supercapacitor electrodes. Chem Soc Rev 38:2520–2531

Simitzis J (1994) Modified polyacrylonitrile for adsorption applications. Acta Polym 45:104–109

Senthilkumaar S, Varadarajan PR, Porkodi K, Subbhuraam CV (2005) Adsorption of methylene blue onto jute fiber carbon: kinetics and equilibrium studies. J Colloid Interface Sci 284:78–82

Dalton S, Heatley F, Budd PM (1999) Thermal stabilization of polyacrylonitrile fibres. Polymer 40:5531–5543

Karacan I, Erdogan G (2012) The influence of thermal stabilization stage on the molecular structure of polyacrylonitrile fibers prior to the carbonization stage. Fiber Polym 13(3):295–302

Zhu Y, Wilding MA, Mukhopadhyay SK (1996) Estimation, using infrared spectroscopy, of the cyclization of poly(acrylonitrile) during the stabilization stage of carbon fibre production. J Mater Sci 31:3831–3837. doi:10.1007/BF00352799

Simitzis J, Soulis S (2008) Correlation of chemical shrinkage of polyacrylonitrile fibres with kinetics of cyclization. Polym Int 57:99–105

Simitzis J (1975) Einfluss von Copolymergehalt und Verstreckung von PAN-Fasern auf das Pyrolyseverhalten und die Eigenshaften daraus Hergestellter Kohlenstoff-Fasern

Bajaj P, Roopanwal AK (1997) Thermal stabilization of acrylic precursors for the production of carbon fibers: an overview. Polym Rev 37:97–147

Bashir Z (1991) A critical review of the stabilisation of polyacrylonitrile. Carbon 29:1081–1090

Li K, Ling L, Lu C, Liu Z, Liu L, Mochida Ι (2001) Influence of CO-evolving groups on the activity of activated carbon fiber for SO2 removal. Fuel Process Technol 70(8):151–158

Memetea LT, Billingham NC, Then ETH (1995) Hydroperoxides in role in carbon-fibre formation. Polym Degrad Stabil 47:189–201

Simitzis JC (1997) Polyacrylonitrile. In: Olabisi O (ed) Handbook of thermoplastics. Marcel Dekker, New York, pp 177–201

Khanderi J, Schneider JJ (2009) Polyacrylonitrile-derived 1D carbon structures via template wetting and electrospinning. Z Anorg Allg Chem 635:2135–2142

Lee S, Kim J, Ku BC, Kim J, Joh HI (2012) Structural Evolution of Polyacrylonitrile Fibers in Stabilization and Carbonization. Adv Chem Eng Sci 2:275–282

Chrysikos K, Soulis S, Kartsonakis IA, Charitidis K, Simitzis J. 9th Hellenic scientific conference of chemical engeneering, 23–25 May 2013; National Technical University of Athens (NTUA), Zographou Campus, Athens, Greece: National Technical University of Athens (NTUA), p 6

Burlant WJ, Parsons JL (1956) Pyrolysis of polyacrylonitrile. J. Polym. Sci. 22(101):249–256

Fielder AK, Fitzer E, Müller DJ (1971) ACS-symposium; March 28–Apr 2, Los Angeles

Bilibio U, Oliveira LH, Ferreira VS, Trindade MAG (2014) Enhanced simultaneous electroanalytical determination of two fluoroquinolones by using surfactant media and a peak deconvolution procedure. Microchem J 116:47–54

Eastwood BJ, Christensen PA, Armstrong RD, Bates NR (1999) Electrochemical oxidation of a carbon black loaded polymer electrode in aqueous electrolytes. J Solid State Electrochem 3:179–186

Gosser DKJ (1993) Cyclic voltammetry/simulation and analysis of reaction mechanisms. VCH Publishers Inc., New York

Miranda-Hernandez M, Rincon ME (2005) Carbon paste electrodes: correlation between the electrochemical hydrogen storage capacity and the physicochemical properties of carbon blacks. J Solid State Electrochem 9:646–652

Burke LD, Lyons MEG (1986) Electrochemistry of hydrous oxide films. In: White RE, Bockris JO, Conway BE (eds) Modern aspects of electrochemistry. Plenum Press, New York, pp 191–198

Lombardi I, Bestetti M, Mazzocchia C, Cavallotti PL, Ducati U (2004) Electrochemical characterization of carbon nanotubes for hydrogen storage. Electrochem Solid State 7:A115–A118

Guenbour A, Iken H, Kebkab N, Bellaouchou A, Boulif R, Bachir AB (2006) Corrosion of graphite in industrial phosphoric acid. Appl Surf Sci 252:8710

Nakao F, Takenaka Y, Asai H (1992) Surface characterization of carbon fibres and interfacial properties of carbon fibre composites. Composites 23:365–372

Rudorff W (1940) Zeitshrift fur anorganishe und allgemeine Chemie. J Phys Chem B 45:1–50

Theodoridou E, Besenhard JO, Fritz HP (1981) Chemically modified carbon fibre electrodes part I. Bulk-functionalized carbon fibres. J Electroanal Chem 122:67–71

Suárez D, Menéndez JA, Fuente E, Montes-Morán MA (1999) Contribution of pyrone-type structures to carbon basicity: an ab initio study. Langmuir 15:3897–3904

Strelko VV, Kartel NT, Dukhno IN, Kuts VS, Clarkson RB, Odintsov BM (2004) Characterisation of the surface of oxidised carbon adsorbents. Surf Sci 548:281–290

Botelho EC, Figiel L (2003) Rezende MC, Lauke B. Mechanical behavior of carbon fibre reinforced polyamide composites. Compos Sci Technol 63:1843–1855

Lacefield W, Clare A (1999) Ceramics and Glasses. In: von Recum AF (ed) Handbook of biomaterials evaluation. Taylor & Francis, London, pp 143–154

Pinero ER, Amoros DC, Solano AL, Find J, Wild U, Schlögl R (2002) Structural characterization of N-containing activated carbon fibers prepared from a low softening point petroleum pitch and a melamine resin. Carbon 40:597–608

Selin M, König M (2009) Regression analysis of thermal conductivity based on measurements of compacted graphite irons. Metall Mater Trans A 40(13):3235–3244

Acknowledgements

The author P. Georgiou wants to thank the Greek State Scholarship’s Foundation (IKY) for its PhD scholarship. Additionally, many thanks are expressed to my cousin Mrs. A. Photiou, MSc., Chemical Engineer, for her help with some of the repetitive experiments of thermal oxidation treatment and our collaboration during her diploma thesis and also many thanks are expressed to Dr. John Walton, Surface Analysis Co-Ordinator at The University of Manchester for the XPS measurements and analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Simitzis, J.C., Georgiou, P.C. Functional group changes of polyacrylonitrile fibres during their oxidative, carbonization and electrochemical treatment. J Mater Sci 50, 4547–4564 (2015). https://doi.org/10.1007/s10853-015-9004-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9004-2