Abstract

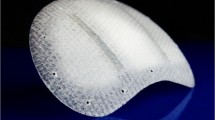

The composition and properties of silicone–hollow microsphere composites were studied in view of establishing a new type of maxillofacial prosthesis material. Two types of microspheres were used in different concentrations and were well dispersed in the silicone matrix. The mechanical properties of the composites were evaluated. Expancel hollow microspheres improve the density, Shore A hardness, and breaking elongation of the materials but degrade their tensile strength, tear strength, and dynamic mechanical properties, while opposite trends were observed with hollow SiO2 microspheres. Ideal properties for maxillofacial prosthetic applications can thereby be obtained by blending the two types of hollow microspheres in specific proportions.

Similar content being viewed by others

References

Barnhart GW (1960) A new material and technic in the art of somato prostheses. J Dent Res 39(4):836–844

Sanchez RA, Moore DJ, Cruz DL et al (1992) Comparison of the physical properties of two types of polydimethyl siloxane for fabrication of facial prostheses. J Prosthet Dent 67(5):679–682

Polyzois GL, Hensten-Pettersen A, Kullmann A (1994) An assessment of the physical properties and biocompatibility of three silicone elastomers. J Prosthet Dent 71(5):500–504

Lai JH, Wang LL, Ko CC et al (2002) New organosilicone maxillofacial prosthetic materials. Dent Mater 18(3):281–286

Aziz T, Waters M, Jagger R (2003) Analysis of the properties of silicone rubber maxillofacial prosthetic materials. J Dent 31(1):67–74

Ochiai KT, Nishimura RD, Sheh EC et al (2000) Fabrication of a custom silicone tracheostomal prostheses. J Prosthet Dent 83(5):578–581

Su F, Zhao YM, Shao LQ et al (2006) The test of the mechanical properties of SY-28, SY-20 and MDX-4-4210 silicone elastomers. J US-China Med Sci 3(2):36–40

Craig RG, Koran A, Yu R et al (1978) Color Stability of Elastomers for Maxillofacial Appliances. J Dent Res 57(9):866–871

Kanazawa T, Yoshida H, Furuya Y et al (2000) Sectional prostheses with hollow obturator portion made of thin silicone layer over resin frame. J Oral Rehabil 27(9):760–764

Aziz T, Waters M, Jagger R (2003) Surface modification of an experimental silicone rubber maxillofacial material to improve wettability. J Dent 31(3):213–216

Murata H, Hong G, Hamada T et al (2003) Dynamic mechanical properties of silicone maxillofacial prosthetic materials and the influence of frequency and temperature on their properties. Int J Prosthodont 16(4):369–374

Han Y, Kiat-amnuay S, Powers JM et al (2008) Effect of nano-oxide concentration on the mechanical properties of a maxillofacial silicone elastomer. J Prosthet Dent 100(6):465–473

Hatamleh MM, Haylock C, Watson J et al (2010) Maxillofacial prosthetic rehabilitation in the UK: a survey of maxillofacial prosthetists’ and technologists’ attitudes and opinions. Int J Oral Maxillofac Surg 39(12):1186–1192

Liu Q, Shao LQ, Xiang HF et al (2013) Biomechanical characterization of a low density silicone elastomer filled with hollow microspheres for maxillofacial prostheses. J Biomater Sci Polym Ed 24(11):1378–1390

Fu H, Rahaman MN, Day DE, Brown RF (2011) Hollow hydroxyapatite microspheres as a device for controlled delivery of proteins. J Mater Sci 22(3):579–591

Wang LL, Liu Q, Jing DD et al (2014) Biomechanical properties of nano-TiO2 addition to a medical silicone elastomer: the effect of artificial aging. J Dent 42:475–483

Abazingea M, Jacksonb T, Yang Q (2000) In vitro and in vivo characterization of biodegradable enoxacin microspheres. Eur J Pharm Biopharm 49(2):191–194

Varlamova LP, Cherkasov VK, Semenov NM et al (2009) Effect of the modification of aluminosilicate ash microsphere surfaces on physical-mechanical properties of polyurethane foam. Russ J Appl Chem 82(6):1098–1101

Simon MW, Stafford KT, Ou DL (2008) Nanoclay reinforcement of liquid silicone rubber. J Inorg Organomet Polym Mater 18(3):364–373

Kim J, Yoon S, Yu J (2003) Fabrication of nanocapsules with Au particles trapped inside carbon and silica nanoporous shells. Chemistry Communication. 21(6):790–791

Stevenson I, David L, Gauthier C et al (2001) Influence of SiO2 fillers on the irradiation ageing of silicone rubbers. Polymer 42(22):9287–9292

Chukhlanov VY, Sysoev EP (2000) Use of hollow glass microspheres in organosilicon syntact foam plastics. Glass Ceram 57:47–48

Liliane B (2004) Elastomeric composites. I. Silicone composites. J Appl Polym Sci 93(5):2095–2104

Kosmalska A, Zaborski M, Sokolowska J (2010) The Properties of SiO2/dye composite pigments and their applications for silicone rubber. Polimery. 55(3):215–221

Kulik VM, Boiko AV, Bardakhanov SP et al (2011) Viscoelastic properties of silicone rubber with admixture of SiO2 nanoparticles. Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing 18:5729–5732

Moore DJ (1994) Overview of materials for extra—oral prostheses[C].The paper of the first international congress on facial prostheses, pp 3–27

Murata H, Hong G, Hamada T et al (2003) Dynamic mechanical properties of silicone maxillofacial prosthetic materials and the influence of frequency and temperature on their properties. International Journal of Prosthodontics 16(4):369–374

Santawisuk W, Kanchanavasita W, Sirisinha C et al (2010) Dynamic viscoelastic properties of experimental silicone soft lining materials. Dent Mater J 29(4):454–460

Kaneko H, Inoue K, Tominaga Y et al (2002) Damping performance of polymer blend/organic filler hybrid materials with selective compatibility. Mater Lett 52:96–99

Wu CY, Wu GZ, Wu CF (2006) Dynamic mechanical properties in blends of poly(styrene-b-isoprene-b-styrene) with aromatic hydrocarbon resin. J Appl Polym Sci 102(5):4157–4164

Acknowledgements

The work was supported in part by Grants from the National Natural Science Foundation of China (No. 31070857), the Guangdong Province Medical Research Foundation (No. A2014412), the Nanfang Hospital President Foundation (No. 2013B013), the Nanfang Hospital New Technology Foundation (No. 2013014), the Nanfang Hospital Education Foundation (No. 14NJ-MS10), and the Southern Medical University New Started Scientific Research Projects (No. PY2013N038).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, Q., Shao, L., Fan, H. et al. Characterization of maxillofacial silicone elastomer reinforced with different hollow microspheres. J Mater Sci 50, 3976–3983 (2015). https://doi.org/10.1007/s10853-015-8953-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-8953-9