Abstract

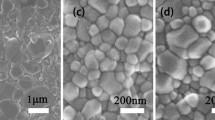

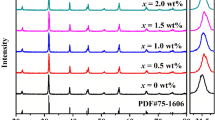

Fine-grained BaTiO3-based ceramics with core–shell structures were prepared using the chemical coating method and the solid-state method. The sintering behavior and microstructure evolution were investigated for the samples prepared using different methods. The dielectric properties of modified BaTiO3 ceramics were also investigated, and the TEM–EDS results provided a detailed explanation for the different temperature coefficient of capacitance behaviors. In addition, the insulation resistivity for the ceramic samples under elevated temperature and high voltages was observed. The highly accelerated lifetime test results indicate that the samples prepared by the chemical coating method exhibited higher insulation resistance and a smaller degradation rate. Impedance analysis demonstrated that the grain boundary activation energy was much higher for the samples prepared by the chemical coating method.

Similar content being viewed by others

References

Kishi H, Mizuno Y, Chazono H (2003) Base-metal electrode-multilayer ceramic capacitors: past, present and future perspectives. Jpn J Appl Phys 42(1):1–15

Pan M-J, Randall CA (2010) A Brief Introduction to Ceramic Capacitors. IEEE Electr Insul M 26(3):44–50

Sakabe Y, Reynolds T (2002) Base-metal electrode capacitors. Am Ceram Soc Bull 81(10):24–26

Yang GY, Dickey EC, Randall CA, Barber DE, Pinceloup P, Henderson MA, Hill RA, Beeson JJ, Skamser DJ (2004) Oxygen nonstoichiometry and dielectric evolution of BaTiO3. Part I—improvement of insulation resistance with reoxidation. J Appl Phys 96(12):7492

Ferkel H, Hellmig RJ (1999) Effect of nanopowder deagglomeration on the densities of nanocrystalline ceramic green bodies and their sintering behaviour. Nanostruct Mater 11(5):617–622

Lee JY, Lee JH, Hong SH, Lee YK, Choi JY (2003) Coating BaTiO3 Nanolayers on Spherical Ni Powders for Multilayer Ceramic Capacitors. Adv Mater 15(19):1655–1658

Yaseen H, Baltianski S, Tsur Y (2006) Effect of Incorporating Method of Niobium on the Properties of Doped Barium Titanate Ceramics. J Am Ceram Soc 89(5):1584–1589

Tian Z, Wang X, Shu L, Wang T, Song T-H, Gui Z, Li L (2009) Preparation of Nano BaTiO3-Based Ceramics for Multilayer Ceramic Capacitor Application by Chemical Coating Method. J Am Ceram Soc 92(4):830–833

Zhang Y, Wang X, Tian Z, Hur K-H, Li L (2011) Preparation of BME MLCC Powders by Aqueous Chemical Coating Method. J Am Ceram Soc 94(10):3286–3290

Zhang Y, Wang X, Kim J-Y, Tian Z, Fang J, Hur K-H, Li L (2012) High Performance BaTiO3-Based BME-MLCC Nanopowder Prepared by Aqueous Chemical Coating Method. J Am Ceram Soc 95(5):1628–1633

Waser R, Baiatu T, Hardtl KH (1990) DC Electrical Degradation of Perovskite-type Titanates: I Ceramics. J Am Ceram Soc 73(6):1645–1653

Baiatu T, Waser R, Hardtl KH (1990) DC Electrical Degradation of Perovskite-Type Titanates: III, A Model of the Mechanism. J Am Ceram Soc 73(6):1663–1673

Yasukawa K, Nishimura M, Nishihata Y, Ji Mizuki (2007) Core-shell structure analysis of BaTiO3 ceramics by synchrotron X-ray diffraction. J Am Ceram Soc 90(4):1107–1111

Hennings D, Rosenstein G (1984) Temperature-Stable Dielectrics Based on Chemically Inhomogeneous BaTiO3. J Am Ceram Soc 67(4):249–254

Yang GY, Lian GD, Dickey EC, Randall CA, Barber DE, Pinceloup P, Henderson MA, Hill RA, Beeson JJ, Skamser DJ (2004) Oxygen nonstoichiometry and dielectric evolution of BaTiO3. Part II - insulation resistance degradation under applied dc bias. J Appl Phys 96(12):7500–7508

Polotai AV, Fujii I, Shay DP, Yang G-Y, Dickey EC, Randall CA (2008) Effect of Heating Rates during Sintering on the Electrical Properties of Ultra-Thin Ni-BaTiO3 Multilayer Ceramic Capacitors. J Am Ceram Soc 91:2540–2544

Tian Z, Wang X, Zhang Y, Song T-H, Hur KH, Li L (2011) Fabrication of BaTiO3-Based Dielectrics for Ultrathin-Layer Multilayer Ceramic Capacitor Application by a Modified Coating Approach. Jpn J Appl Phys 50(2):025801

Chang C-Y, Wang W-N, Huang C-Y, Alford N (2013) Effect of MgO and Y2O3 Doping on the Formation of Core-Shell Structure in BaTiO3 Ceramics. J Am Ceram Soc 96:2570–2576

Sinclair DC, West AR (1989) Impedance and modulus spectroscopy of semiconducting BaTiO3 showing positive temperature-coefficient of resistance. J Appl Phys 66(8):3850–3856

Irvine JTS, Sinclair DC, West AR (1990) Electroceramics: characterization by impedance spectroscopy. Adv Mater 2(3):132–138

Vollman M, Waser R (1994) Grain-Boundary Deffect Chemistry of Acceptor-doped Titanates-space-charge Layer Width. J Am Ceram Soc 77(1):235–243

Guo X, Fleig J, Maier J (2001) Separation of Electronic and Ionic Contributions to the Grain Boundary Conductivity in Acceptor-Doped SrTiO3. J Electrochem Soc 148(9):J50–J53

Jamnik J, Maier J (1999) Treatment of the Impedance of Mixed Conductors Equivalent Circuit Model and Explicit Approximate Solutions. J Electrochem Soc 146(11):4183–4188

Kaneda K, Lee S, Donnelly NJ, Qu W, Randall CA, Mizuno Y (2011) Kinetics of Oxygen Diffusion into Multilayer Ceramic Capacitors During the Re-oxidation Process and its Implications on Dielectric Properties. J Am Ceram Soc 94(11):3934–3940

Donnelly NJ, Randall CA (2010) Mixed conduction and chemical diffusion in a Pb(Zr0.53, Ti0.47)O3 buried capacitor structure. Appl Phys Lett 96(5):052906

Yoon S-H, Randall CA, Hur K-H (2010) Effect of acceptor concentration on the bulk electrical conduction in acceptor (Mg)-doped BaTiO3. J Appl Phys 107(10):103721

Lai W, Haile SM (2005) Impedance spectroscopy as a tool for chemical and electrochemical analysis of mixed conductors: a case study of ceria. J Am Ceram Soc 88(11):2979–2997

Boukamp BA (1986) A Nonlinear Least-Squares Fit Procedure for Analysis of Immittance Data of Electrochemical Systems. Solid State Ion 20(1):31–44

Acknowledgements

This work was supported by the Ministry of Sciences and Technology of China through the National Basic Research Programme of China (973 Programme 2009CB623301), the National Natural Science Foundation of China for Creative Research Groups (Grant No.51221291), the National Natural Science Foundation of China for distinguished young scholars (Grant No. 50625204), the National Natural Science Foundation of China (Grant No. 51272123), and Samsung Electro-Mechanics Co., Ltd.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gong, H., Wang, X., Zhang, S. et al. Sintering behavior and reliability characteristics of BaTiO3-based ceramics prepared by different methods. J Mater Sci 50, 3523–3530 (2015). https://doi.org/10.1007/s10853-015-8896-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-8896-1