Abstract

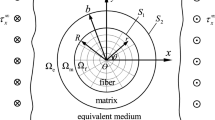

In the present study, the consistent effective elastic properties of straight, circular carbon nanotube epoxy composites are derived using the micromechanics theory. The CNT composites are known to provide high stiffness and elastic properties when the shape of the fibers is cylindrical and straight. Accordingly, in the present work, the effective elastic moduli of composite are newly obtained for straight, circular CNTs aligned in the specified direction as well as distributed randomly in the matrix. In this direction, novel analytical expressions are proposed for four cases of fiber property. First, aligned, and straight CNTs are considered with transverse isotropy in fiber coordinates, and the composite properties are also transversely isotropic in global coordinates. The short comings in the earlier developments are effectively addressed by deriving the consistent form of the strain tensor and the stiffness tensor of the CNT nanocomposite. Subsequently, effective relations for composites reinforced with aligned, straight CNTs but fibers isotropic in local coordinates are newly developed under hydrostatic loading. The effect of the unsymmetric Eshelby tensor for cylindrical fibers on the overall properties of the nanocomposite is included by deriving the strain concentration tensors. Next, the random distribution of CNT fibers in the matrix is studied with fibers being transversely isotropic as well as isotropic when CNT nanocomposites are subjected to uniform loading. The corresponding relations for the effective elastic properties are newly derived. The modeling technique is validated with results reported, and the variations in the effective properties for different CNT volume fractions are presented.

Similar content being viewed by others

References

Iijima S (1991) Lett Nat 354(7):56

Rao AM, Andrews R, Derbyshire F (1998) Nanotube composites carbon fibers. Energeia 9(6):1

Shaffer MSP, Windle AH (1999) Adv Mater 11(11):937

Qian D, Dickey EC, Andrews R, Rantell T (2000) Appl Phys Lett 76(20):2868

Thostenson ET, Chou T-W (2002) J Phys D Appl Phys 35:L77

Curran SA, Ajayan PM, Blau WJ, Carroll DL, Coleman JN, Dalton AB, Davey AP, Drury A, McCarthy B, Maier S, Strevens AA (1998) Adv Mater 10:1091

Fisher FT, Bradshaw RD, Brinson LC (2002) Appl Phys Lett 80(24):4647

Bower C, Rosen R, Han J, Zhou O (1999) Appl Phys Lett 74(22):3317

Frankland SJV, Harik VM, Odegard GM, Brenner DW, Gates TS (2003) Compos Sci Technol 63:1655

Han Y, Elliott J (2007) Comput Mater Sci 39:315

Fornes TD, Paul DR (2003) Polymer 44:4993

Sheng N, Boyce MC, Parks DM, Rutledge GC, Abes JI, Cohen RE (2004) Polymer 45:487

Odegard GM, Clancy TC, Gates TS (2005) Polymer 46(2):553

Fisher FT, Bradshaw RD, Brinson LC (2003) Compos Sci Technol 63(11):1689

Bradshaw RD, Fisher FT, Brinson LC (2003) Compos Sci Technol 63(11):1705

Zhu YF, Ma C, Zhang W, Zhang RP, Koratkar N, Liang J (2009) J Appl Phys 105(054319):1

Seidel GD, Lagoudas DC (2006) Mech Mater 38:884

Anthoulis GI, Kontou E (2008) Polymer 49:1934

Song YS, Youn JR (2006) Polymer 47(5):1741

Shi DL, Feng XQ, Huang YY, Hwang KC, Gao H (2004) J Eng Mater Technol 126:250

Shi DL, Feng XQ, Huang YY, Hwang KC (2004) Key Eng Mater 261–263:1487

Shi DL, Feng XQ, Jiang H, Huang YY, Hwang KC (2005) Int J Fract 134:369

Wuite J, Adali S (2005) Compos Struct 71:388

Maghamikia Sh, Jam JE (2011) J Mech Sci Technol 25(11):2805

Yas MH, Heshmati M (2012) Appl Math Model 36:1371

Mori T, Tanaka K (1973) Acta Metal 21:571

Mura T (1987) Micromechanics of defects in solids. Martinus Nijhoff, Leiden

Jarali CS (2012) Micromechanics and modelling of adaptive shape memory composites. Lambert, Saarbrücken

Hill R (1965) J Mech Phys Solids 13:89

Acknowledgements

Chetan S. Jarali is thankful and gratefully acknowledges Dr. Björn Kiefer, Assistant Professor, Mechanics of Functional Materials, Institute of Mechanics, Department of Mechanical Engineering, TU Dortmund, Leonhard-Euler-Strasse 5, D-44227 Dortmund, Germany for technical discussions on the present work. Additionally, the authors of the present work gratefully acknowledge Prof. Xi-Qiao Feng, Prof. Yonggang Y. Huang, and Prof. Huajian Gao for helpful discussions regarding the research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jarali, C.S., Patil, S.F., Pilli, S.C. et al. Modeling the effective elastic properties of nanocomposites with circular straight CNT fibers reinforced in the epoxy matrix. J Mater Sci 48, 3160–3172 (2013). https://doi.org/10.1007/s10853-012-7093-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7093-8