Abstract

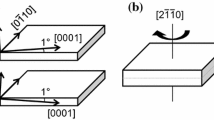

LiNbO3 is a ferroelectric material with a rhombohedral R3c structure at room temperature. A LiNbO3 bicrystal with a \( \{ {\overline{1} 2\overline{1} 0} \}/ {\langle}10\overline{1} 0{\rangle}\) 1° low-angle tilt grain boundary was successfully fabricated by diffusion bonding. The resultant boundary was then investigated using high-resolution TEM. The boundary composed a periodic array of dislocations with \( b = { 1}/ 3{\langle} \overline{1} 2\overline{1} 0{\rangle} \). They dissociated into two partial dislocations by climb. A crystallographic consideration suggests that the Burgers vectors of the partial dislocations should be \( 1/ 3{\langle}01\overline{1} 0{\rangle} \) and \( 1/ 3{\langle}\overline{1} 100{\rangle} \), and a stacking fault on \( \{ {\overline{1} 2\overline{1} 0} \} \) is formed between the two partial dislocations. From the separation distance of a partial dislocation pair, a stacking fault energy on \( \{ {\overline{1} 2\overline{1} 0} \} \) was estimated to be 0.25 J/m2 on the basis of isotropic elasticity theory.

Similar content being viewed by others

References

Abrahams SC, Reddy JM, Bernstein JL (1966) J Phys Chem Solids 27:997

Weis RS, Gaylord TK (1985) Appl Phys A 37:191

Yamada T, Niizeki N, Toyoda H (1967) Jpn J Appl Phys 6:151

Lines ME, Glass AM (1979) Principles and applications of ferroelectrics and related materials. Clarendon, Oxford

Donnerberg H, Tomlinson SM, Catlow CRA, Schirmer OF (1991) Phys Rev B 44:4877

Schirmer OF, Thiemann O, Wohlecke M (1991) J Phys Chem Solids 52:185

Iyi N, Kitamura K, Izumi F, Yamamoto JK, Hayashi T, Asano H, Kimura S (1992) J Solid State Chem 101:340

Wilkinson AP, Cheetham AK, Jarman RH (1993) J Appl Phys 74:3080

Malovichko G, Grachev V, Schirmer O (1999) Appl Phys B 68:785

Safaryan FP, Feigelson RS, Petrosyan AM (1999) J Appl Phys 85:8079

Vere AW (1968) J Mater Sci 3:617. doi:10.1007/BF00757908

Blistanov AA, Nosova IV, Tagieva MM (1975) Kristallografiya 20:666

Blistanov AA, Nosova IV, Tagieva MM (1976) Kristallografiya 21:217

Fries E, Péter A (1987) Rev Phys Appl 22:1353

Ikuhara Y, Nishimura H, Nakamura A, Matsunaga K, Yamamoto T, Lagerlöf KPD (2003) J Am Ceram Soc 86:595

Nakamura A, Matsunaga K, Yamamoto T, Ikuhara Y (2006) Phil Mag 86:4657

Tochigi E, Shibata N, Nakamura A, Mizoguchi T, Yamamoto T, Ikuhara Y (2010) Acta Mater 58:208

De Souza RA, Fleig J, Maier J, Kienzle O, Zhang ZL, Sigle W, Ruhle M (2003) J Am Ceram Soc 86:922

Lagerlöf KPD, Mitchell TE, Heuer AH, Riviere JP, Cadoz J, Castaing J, Phillips DS (1984) Acta Metall 32:97

Nakamura A, Yamamoto T, Ikuhara Y (2002) Acta Mater 50:101

Ballman AA (1965) J Am Ceram Soc 48:112

Carruthers JR, Peterson GE, Grasso M, Bridenbaugh PM (1971) J Appl Phys 42:1846

Nakamura A, Tochigi E, Shibata N, Yamamoto T, Ikuhara Y (2009) Mater Trans 50:1008

Frank FC (1951) Phil Mag 42:809

Hirth JP, Lothe J (1982) Theory of dislocations 2nd. Krieger Publishing Company, Malabar

Smith RT, Welsh FS (1971) J Appl Phys 42:2219

Tomeno I, Matsumura S (1987) J Phys Soc Jpn 56:163

Williams DB, Carter CB (1996) Transmission electron microscopy. Springer, New York

Kitamura K, Yamamoto JK, Iyi N, Kirnura S, Hayashi T (1992) J Cryst Growth 116:327

Kilaas R (1991) HREM image simulation. Proc 49th EMSA Meeting, pp 528–529

Du K, Rühle M (2008) J Microsc 232:137

Acknowledgements

The authors wish to express their gratitude to Prof. Y. Ikuhara and Prof. N. Shibata for fruitful discussion and encouragement. They also thank Ms. N. Uchida for technical support in TEM operation. Part of this work was supported by a Grant-in-Aid on Priority Areas “Nano Materials Science for Atomic-scale Modification” (no. 19053001). The authors acknowledge the support of National Center for Electron Microscopy, Lawrence Berkeley Laboratory on the simulated HRTEM images, which is supported by the U.S. Department of Energy under Contract # DE-AC02-05CH11231. E. T. was supported by the JSPS postdoctoral fellowship for research abroad.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Particle-like regions with moiré at the boundary

Figure 10a shows a STEM bright-field image taken from the boundary in the fabricated bicrystal. The particle-like regions with moiré were often observed at the boundary, as can be seen in this figure. There may be some impurities in the region with moiré; therefore, a line analysis along the dotted line in (a) and a spot analysis for the region with moiré were performed using an energy dispersive X-ray spectrometer (EDS), as shown in Fig. 10b, c, respectively. In (b), it was found that Nb and O ions are constantly present in either region, with and without moiré. Note that Li ions cannot be detected because Li generates an X-ray with energy that is too low for the EDS detector. It can be also seen in (c) that only the Nb, O, Fe and Cr elements are significantly detected in the region with moiré. Here, small amounts of Fe and Cr can be derived from the stainless-steel single-hole mesh attached to the specimen, as described in the experimental procedure. Their signals were detected from the bulk as well. In other words, particle-like regions with moiré are not brought about by a definite impurity.

Here we consider the observed spacing of the moiré fringes, which includes the information concerning a degree of lattice distortion. In general, we observed moiré fringes in the following two cases. First, when two regions with a rotation relationship (rotation moiré) overlap along the incident beam direction. Second, when two regions with slightly different lattice spacing (translational moiré) overlap without rotation. Under the two-beam approximation in TEM, the rotational moiré fringes are parallel to the excited diffraction vector, whereas the translational moiré fringes are normal to the vector [28]. As observed in Fig. 4a, the moiré fringes are normal to the excited diffraction vector. This means that the moiré fringes observed in this study are due to the overlap of two regions with slightly different crystal lattice constants. In this case, the spacing of the moiré fringes in a bright-field image is decided by the difference and an excited diffraction vector [28]. It was estimated from the image of Fig. 4a and Fig. 10a that the spacing of the moiré fringes is about 16 nm along [\( \overline{1} 2\overline{1} 0 \)]. The relation between the spacing d m and the excited diffraction vector \( g( 1\overline{ 2} 10) \) is given as \( |g( 1\overline{ 2} 10)| \times s \) = d −1m , where s is the displacement ratio of the crystal lattice constant along [\( \overline{1} 2\overline{1} 0 \)] to the bulk. Thus, s was estimated to be about 0.016 for \( |g( 1\overline{ 2} 10)| \) = 3.88 nm−1. This indicates that the region with moiré has a different crystal lattice constant of 1.6% from bulk.

The value of 1.6% seems to be large for a simple lattice distortion. To account for this, the following two possibilities are proposed. One is a break in stoichiometry around the boundary. The ratio of constituent ions around the boundary may have a deviation from the bulk because LiNbO3 can be non-stoichiometric. The deviation of the ratio affects the lattice parameter of LiNbO3; the deviation might be a reason for the change of the crystal lattice constant. However, the typical variation of lattice constants due to the deviation is less than 0.2% [29]. The other possibility is the presence of a space charge around the boundary. Even if an electric field of 20 kV/mm is applied to LiNbO3, however, the lattice strain by the piezoelectric reaction does not reach 0.1% [3]. It seems that it is difficult to explain the change of 1.6% by theories referring to the bulk structure. Thus, it is suggested that localized regions near the boundary may be distorted due to local and extraordinary changes in stoichiometry or space charge.

Appendix 2: Bright points on the HRTEM image of LiNbO3

Figure 11 shows the simulated HRTEM images of LiNbO3 bulk crystal observed along the [\( 10\overline{1} 0 \)] zone axis obtained with the MacTempas program [30]. An experimental HRTEM image of the bulk crystal taken from Fig. 5 is also shown at the upper right. The supercell in the simulation was an orthorhombic structure containing 60 atoms (5.418 × 8.992 × 13.86 Å3), as shown in the insets of the images, and the simulated images are described twice in the supercell along the [\( 1\overline{2} 10 \)] axis. The Debye–Waller factors of Li, Nb, and O were set to 0.94, 0.50, and 0.43 Å2, respectively [1]. The simulation was performed within the range of defocus from −50 to −10 nm and the sample thickness was 9.8–32.1 nm. The Scherzer defocus of the JEM-4010 is −34 nm. It is found that black contrasts correspond to the atomic positions in the 9.8-nm-thick images, whereas strong white contrasts correspond to the oxygen columns in the 20.5–31.2-nm-thick images. The contrasts of the 15.2-nm-thick images are more complicated and thus difficult to associate with atomic positions. In the experimental image, the three rows of white spots along the [0001] direction correspond to alternate basal planes (i.e., (0003) lattice planes), whereas the strong contrasts of the simulated images correlate with the intervals of successive basal planes (i.e., (0006) lattice planes). Here, the contributions of the (0006) atomic planes to the HRTEM image contrasts should be equivalent at the exact [\( 10\overline{1} 0 \)] incidence. It has been reported that the misalignment of the electron beam and crystal orientation can cause strong contrasts in the (0003) lattice planes in the HRTEM imaging of α-Al2O3 along the [\( 10\overline{1} 0 \)] direction [31]. That is, the mismatch between the experimental and simulated images in LiNbO3 could be due to misalignment effects in the experimental HRTEM observation.

Figures 12a, b show simulated HRTEM images considering the misalignment up to 1.2 mrad with respect to the [0001] and [\( 1\overline{2} 10 \)] rotation axes, where the defocus value is −30 nm in both cases and the sample thickness is 9.8 nm in (a) and 20.5 nm in (b). In the case of 9.8-nm-thick images, the simulated images are not sensitive to misalignment, whereas the 20.5-nm-thick images significantly vary depending on misalignment. The strong contrasts in the 20.5-nm-thick images corresponding to the (0003) lattice planes are enhanced by a misalignment of 0.6 or 1.2 mrad with respect to the [0001] rotation axis. This feature is consistent with the experimental image. In addition, the strong white spots in the simulated images are present at the oxygen columns. Therefore, the white spots in the experimental image probably correspond to the oxygen columns that belong to the alternate basal planes. However, the effects of the factors that have not been experimentally identified still need to be investigated further. Furthermore, quantitative measurements of defocus, sample thickness, and misalignment are required to determine the atomic positions from the experimental image.

Simulated HRTEM images considering a misalignment of up to 1.2 mrad. The horizontal and vertical sets correspond to misalignment with respect to the [0001] and \( [ {1\overline{2} 10} ] \) axes, respectively: a defocus of −30 nm and sample thickness of 9.8 nm, b defocus of −30 nm and sample thickness of 20.5 nm

Rights and permissions

About this article

Cite this article

Nakamura, A., Tochigi, E., Nakamura, Jn. et al. Dislocation structure at a \( \{ {\overline{1} 2\overline{1} 0} \}/ {\langle} 10\overline{1} 0 {\rangle} \) low-angle tilt grain boundary in LiNbO3 . J Mater Sci 47, 5086–5096 (2012). https://doi.org/10.1007/s10853-012-6373-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6373-7