Abstract

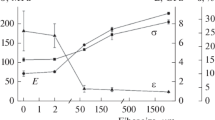

This article presents an investigation into the possible matching of mechanical properties of a polyimide (PI)–carbon nanotube (CNT) composite system to natural cartilage tissue. Currently used ultrahigh molecular weight polyethylene (UHMWPE) used in total joint replacements presents certain drawbacks due to a mismatch in mechanical and tribological properties with those of a natural bone joint. Natural cartilage tissue is a composite material itself, being composed of collagen fibers, hydrophilic proteoglycan molecules, cells and other constituents. The current investigation attempts to mimic the mechanical and tribological properties of natural cartilage tissue by varying the CNT concentration in a PI matrix. Nanoindentation and pin-on-flat tribological tests were conducted for this purpose. It was found that the coefficient of friction (COF) reached a minimum at a concentration of 0.5% CNT (by volume) when articulated against Ti6Al4V alloy. When articulated against Ti6Al4V alloy in the presence of a lubricant, the minimum COF was obtained at a concentration of 0.2% CNT. The maximum penetration depth under nanoindentation varied with CNT concentration and indicated that the mechanical properties could be tailored to match that of cartilage tissue. A closer investigation into this behavior was carried out using scanning electron, transmission electron, and atomic force microscopy. It was noticed that there is good bonding between the CNTs and polyimide matrix. There was a ductile to brittle transition as the concentration of CNT was increased. Competing interactions between nanotube–matrix and nanotube–nanotube are possible reasons for the deformation and friction behavior identified.

Similar content being viewed by others

References

Lewis G (1997) J Biomed Mater Res 38(1):55

Sargeant A, Goswami T (2006) Mater Des 27(4):287

Li S, Burnstein AH (1994) J Bone Joint Surg 76A:1080

Gómez-Barrena E, Chang JD, Li S (1996) In: Pritchard DJ (ed) Instructional course lectures 45. American Academy of Orthopaedic Surgeons, Rosemont, IL

Premnath V, Harris WH, Jasty M, Merill EW (1996) Biomaterials 17:1741

Edidin AA, Pruitt L, Jewett CW, Crane DJ, Roberts D, Kurtz SM (1999) J Arthroplasty 14(5):616

Wang A, Sun DC, Yau SS, Edwards B, Sokol M, Essner A, Polineni VK, Stark C, Dumbleton JH (1997) Wear 203:230

Pruitt LA (2005) Biomaterials 26:905

Pascaud RS, Evans WT, McCullagh PJ, Fitzpatrick DP (1997) Biomaterials 18:727

Kurtz SM, Rimnac CM, Pruitt L, Jewett CW, Goldberg V, Edidin AA (2000) Biomaterials 21:283

Jiang X, Bin Y, Matsuo M (2005) Polymer 46:7418

Shen C, Dumbleton JH (1976) Wear 40:351

Richardson RR, Miller JA, Reichert WM (1976) Biomaterials 14(8):627

Cai H, Yan F, Xue Q (2004) Mater Sci Eng A 364:94

Smart SK, Cassady AI, Lu GQ, Martin DJ (2006) Carbon 44:1034

Cenni E, Granchi D, Arciola CR, Ciapetti G, Savarino L, Stea S (1995) Biomaterials 16(16):1223

Ma L, Sines G (1983) J Biomed Mater Res 51A(1):61

Haubold AD (1983) ASAIO J 6:88

Treacy MMJ, Ebbesen TW, Gibson JM (1996) Nature 381:678

Falvo MR, Clary GJ, Taylor RM, Chi V, Brooks FP, Washburn S (1997) Nature 389:582

Ebbesen TW, Lezec HJ, Hinura H, Bennett JW, Ghaemi HF, Thio T (1996) Nature 382:54

Dai H (2002) Acc Chem Res 35:1035

Buldum A, Lu JP (1999) Phys Rev Lett 83:5050

Zhou X, Shin E, Wang KW, Bakis CE (2004) Comp Sci Technol 64(15):2425

Koratkar N, Suhr J, Joshi A, Kane R, Schadler L, Ajayan P, Bartolucci S (2005) Appl Phys Lett 87(6):063102

Suhr J, Koratkar N, Keblinski P, Ajayan P (2005) Nat Mater 4:134

Koratkar N, Wei BQ, Ajayan PM (2002) Adv Mater 14:997

Yakobson BI, Brabec CJ, Bernholc J (1996) Phys Rev Lett 76(14):2511

Barber AH, Cohen SR, Wagner DH (2003) Appl Phys Lett 82(23):4140

Savage RH (1991) J Appl Phys 19(1):1

Mangalick MC (1974) Carbon 12(5):573

Vander Wal RL, Miyoshi K, Street KW, Tomasek AJ, Peng H, Liu Y, Margrave JL, Khabashesku VN (2005) Wear 259:738

Ni B, Sinott SB (2001) Surf Sci 487:87

Park C, Crooks RE, Siochi EJ, Harrison JS, Evans N, Kenik E (2003) Nanotechnology 14:L11

Banda S (2004) Characterization of aligned carbon nanotubes/polymer composites. MSc thesis, Virginia Commonwealth University, Richmond, VA

Deshmukh S, Ounaies Z (2009) Sens Actuators A Phys 155:246

Ounaies Z, Park C, Lillehei P, Harrison J (2008) J Therm Comp Mater 21:393

Goodfellow Corporation (2010) Oakdale, PA. http://www.goodfellow.com. Accessed 15 August, 2010

Kokubo T, Kushitani H, Sakka S (1990) J Biomed Mater Res 24:721

Mow VC, Ratcliffe A, Poole AR (1992) Biomaterials 13(2):67

Acknowledgements

The authors acknowledge the financial support of US National Science Foundation (0535578). They also wish to thank the support of the Materials Characterization Facility and the Microscopy Imaging Center at the Texas A&M University for surface characterization.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ribeiro, R., Banda, S., Ounaies, Z. et al. A tribological and biomimetic study of PI–CNT composites for cartilage replacement. J Mater Sci 47, 649–658 (2012). https://doi.org/10.1007/s10853-011-5835-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5835-7