Abstract

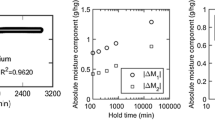

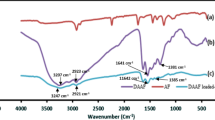

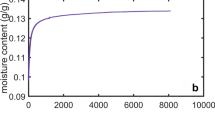

Hygroscopic behaviour is an inherent characteristic of natural fibres which can influence their applications as textile fabrics and composite reinforcements. In this study, the water vapour sorption kinetic properties of cotton, filter paper, flax, hemp, jute, and sisal fibres were determined using a dynamic vapour sorption apparatus and the results were analyzed by use of a parallel exponential kinetics (PEK) model. With all of the fibres tested, the magnitude of the sorption hysteresis observed varied, but it was always greatest at the higher end of the hygroscopic range. Flax and sisal fibres displayed the lowest and highest total hysteresis, respectively. The PEK model, which is comprised of fast and slow sorption components, exhibited hysteresis in terms of mass for both processes between the adsorption and desorption isotherm. The hysteresis derived from the slow sorption process was less than from the fast process for all tested fibres. The fast processes for cotton and filter paper dominated the isotherm process; however, the hemp and sisal fibres displayed a dominant slow process in the isotherm run. The characteristic time for the fast sorption process did not vary between adsorption and desorption, except at the top end of the hygroscopic range. The characteristic time for the slow process was invariably larger for the desorption process. The physical interpretation of the PEK model is discussed.

Similar content being viewed by others

References

Kalia S, Kaith BS, Kaur I (2009) Polym Eng Sci 49:1253

Bakkevig MK, Nielsen R (1994) Ergonomics 36:787

Li Y (2005) Ergonomics 48:234

Guo Y, Li Y, Tokura H, Wong T, Chung J, Wong ASW, Gohel MDI, Leung PHM (2008) Text Res J 78:1057

Hu JY, Li Y, Yeung KW, Wong A, Xu W (2005) Text Res J 75:57

Wambua P, Ivens J, Verpoest I (2003) Compos Sci Technol 63:1259

Bledzki AK, Gassan J, Theis S (1998) Mech Compos Mater 34:563

Cantero G, Arbeliaz A, Liano-Ponte R, Mondargon I (2003) Compos Sci Technol 63:1247

Lundin T, Falk RH, Felton C (2001) In: Proceedings of the sixth international conference on wood fiber–plastic composites, Madison, Wisconsin

Wallenberger FT, Weston N (2004) Natural fibers, plastics and composites. Kluwer Academic Publishers, Massachusetts, USA

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers, and biocomposites. Francis, Taylor

Schirp A, Wolcott M (2005) Wood Fiber Sci 37:643

Schirp A, Wolcott M (2006) J Appl Polym Sci 99:3138

Morris PI, Cooper PA (1997) Forest Prod J 48:86

Lomelí-Ramírez MG, Ochoa-Ruiz HG, Fuentes-Talavera FJ, García-Enriquez S, Cerpa-Gallegos MA, Silva-Guzmán JA (2009) Int Biodeterior Biodegradation 63:1030

Carles JE, Scallan AM (1972) J Appl Polym Sci 17:1855

Hills BP, Wright KM, Belton PS (1989) Mol Phys 67:1309

Ibbett RN, Schuster KC, Fasching M (2008) Polymer 49:5013

Hill CAS (2006) Wood modification—chemical, thermal and other processes. Wiley, Chichester

Papadopoulos AN, Hill CAS (2003) Wood Sci Technol 37:221

Hernández RE (2007) Wood Fiber Sci 39:132

Hill CAS, Norton A, Newman G (2009) J Appl Polym Sci 112:1524

Leisen J, Beckham HW, Benham M (2002) Solid State Nucl Magn Reson 22:409

Hill CAS, Norton A, Newman G (2010) Wood Sci Technol 44:497

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Wood Sci Technol. doi:10.1007/s00226-010-0311-0

Kohler R, Dueck R, Ausperger B, Alex R (2003) Compos Interface 10:255

Hill CAS, Norton A, Newman G (2010) J Appl Polym Sci 116:2166

Xie Y, Hill CAS, Xiao Z, Zaihan J, Militz H, Mai C (2010) J Appl Polym Sci 117:1674

Hill CAS, Norton A, Newman G (2010) Holzforschung 64:469

Okubayashi S, Griesser UJ, Bechtold T (2005) Cellulose 12:403

Okubayashi S, Griesser UJ, Bechtold T (2005) J Appl Polym Sci 97:1621

Kachrimanis K, Noisternig MF, Griesser UJ, Malamataris S (2006) Eur J Pharm Biopharm 64:307

Madamba PS, Driscol RH, Buckle KAJ (1996) Food Eng 29:75

Tang X, De Rooij MR, Van Duynhoven J, Van Breugel KJ (2008) J Microsc 230:100

Rahman MS, Perera CO, Thebaud C (1998) Food Res Int 30:485

Christensen GN (1965) Humidity Moisture 4:279

Rollins ML, Tripp VW (1954) Text Res J 24:345

Krakhmalev VA, Paiziev AA (2006) Cellulose 13:45

Smith CW, Cothren JT (1999) Cotton: origin, history, technology, and protection. Wiley, New York

Gümüşkaya E, Kalyoncu EE, Kirci H (2009) Chem Pap 63:670

Newman RH, Hemmingson JA, Suckling ID (1993) Holzforschung 47:234

Park S, Johnson DK, Ishizawa CI, Parilla PA, Davis MF (2009) Cellulose 16:641

Bertuzzi MA, Armada M, Gottifredi JC (2003) Food Sci Technol Int 9:115

Siau JF (1995) Wood: influence of moisture on physical properties. Department of Wood Science and Forest Products, Virginia Polytechnic Institute and State University, Virginia, USA

Skaar C (1972) Water in wood. Syracuse University Press, Syracuse

Esteban LG, Gril J, de Palacios P, Casasús AG (2005) Ann For Sci 62:275

Shmulsky R, Kadir K, Erickson R (2001) Wood Fiber Sci 33:662

Al-Muhtaseb AH, McMinn WAM, Magee TRA (2004) J Food Eng 6:297

Peralta PN (1995) Wood Fiber Sci 27:250

Peralta PN (1996) Wood Fiber Sci 28:406

Everett DH, Whitton WI (1952) Trans Faraday Soc 48:749

Everett DH, Smith FW (1954) Trans Faraday Soc 50:187

Everett DH (1954) Trans Faraday Soc 50:1077

Everett DH (1955) Trans Faraday Soc 51:1551

Lu Y, Pignatello JJ (2004) J Environ Qual 33:1314

Lu Y, Pignatello JJ (2002) Environ Sci Technol 36:4553

Lu Y, Pignatello JJ (2004) Environ Sci Technol 38:5853

Vrentas JS, Vrentas CM (1996) Macromolecules 29:4391

Okubayashi S, Griesser UJ, Bechtold T (2004) Carbohydr Polym 58:293

Morton WE, Hearle JWS (1997) Physical properties of textile fibers. The Textile Institute, UK

Krabbenhoft K, Damkilde L (2004) Matériaux at Constructions 37:615

Mwaikambo LY (2002) Plant-based resources for sustainable composites. PhD thesis, Department of Engineering and Applied Science, University of Bath, UK

Bolton AJ (1994) Mater Technol 9:12

Baillie C (2000) Green composites: polymer composites and the environment. Woodhead Publishing Limited, New York

Van Den Oever MJA, Bos HL, Van Kemenade MJJM (2000) Appl Compos Mater 7:387

Morvan C, Andeme-Onzighi C, Girault R, Himmelsbach DS, Driouich A, Skin DE (2003) Plant Physiol Biochem 41:935

His I, Morvan C, Andème-Onzighi C, Driouich A (2001) J Histochem Cytochem 49:1525

Crônier D, Monties B, Chabbert B (2005) J Agric Food Chem 53:8279

Vignon MR, Dupeyre D, Garcia-Jaldon C (1996) Bioresour Technol 58:203

Mukhopadhyay AK, Bandyopadhyay SK, Mukhopadhyay U (1985) Text Res J 55:733

Gañan P, Garbizu S, Llano-Ponte R, Mondragon I (2005) Polym Compos 26:121

Martins MA, Kiyohara PK, Joekes I (2004) J Appl Polym Sci 94:2333

Acknowledgements

The support of the Scottish Funding Council for the Joint Research Institute on Civil and Environmental Engineering under the auspices of the Edinburgh Research Partnership is acknowledged. Support from the Carnegie Trust and the Royal Society for financial support for visits of Callum Hill to South Africa is gratefully acknowledged. The support from Chinese National Natural Science Funds (Project No. 30771680) is also appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, Y., Hill, C.A.S., Jalaludin, Z. et al. The dynamic water vapour sorption behaviour of natural fibres and kinetic analysis using the parallel exponential kinetics model. J Mater Sci 46, 479–489 (2011). https://doi.org/10.1007/s10853-010-4935-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4935-0