Abstract

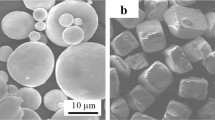

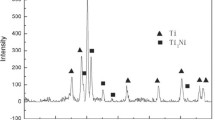

Titanium foams were produced by optimizing a relatively cheap method, sintering under flowing high purity argon gas with fugitive space holder. Removal of the space holder was conducted by dissolution in hot deionized water which renders it possible to minimize contamination of titanium. Titanium foams having various densities between 20 and 70% were manufactured and systematically characterized. Pore sizes varying from a few microns up to 2 mm were obtained. Compatibility with well known porosity–mechanical property formulations of cellular solids was investigated. Pore sizes in the investigated range were found to have a negligible effect on the elastic portion of compressive stress–strain diagram. High strain rate tests revealed that increasing the strain rate increases compressive strength of the titanium foams produced. The onset strain of densification of the produced titanium foams was determined by the recently developed energy absorption efficiency method. The energy absorbed per unit volume was then calculated by referring to the pre-determined onset strain of densification. A plot of energy absorbed per unit volume (EA) as a function of relative density (ρ/ρs) at various strains (%ε) suggested that the data could be fitted to an equation of the form EA = A(%ε)B(ρ/ρs)C, where A, B and C are constants, for both fine- and coarse-pored titanium foams.

Similar content being viewed by others

References

Gibson LG, Ashby MF (1997) Cellular solids, structures and properties, 2nd edn. Cambridge University Press, Cambridge

Banhart J (2002) In: Degischer H-P, Kriszt B (eds) Handbook of cellular metals. Wiley-VCH, Weinheim, p 313

Thelen S, Barthelat F, Brinson LC (2004) J Biomed Mater Res 69A:601

Salimon A, Brechet Y, Ashby MF, Greer AL (2005) J Mater Sci 40:5793. doi:https://doi.org/10.1007/s10853-005-4993-x

Balch DK, O’Dawyer JG, Davis GR, Cady CM, Gray GT, Dunand DC (2005) Mater Sci Eng A 391:408

Park C, Nutt SR (2002) Mater Sci Eng A 323:358

Tuncer N, Arslan G (2007) Effect of processing parameters on compressive behavior of Ti foams. In: MetFoam 2007 conference on porous metals and metallic foams proceedings, Montreal, p 287

ASTM designation F67–89 (1994) Standard specification of unalloyed titanium for surgical implants. ASTM, Philadelphia, PA, USA

Imwinkelried T (2007) J Biomed Mater Res A 81:964

Bram M, Schiefer H, Bogdanski D, Köller M, Buchkremer HP, Stöver D (2006) Met Powder Rep 61(2):26

Chichili DR, Ramesh KT, Hemker KJ (1998) Acta Mater 46:1025

Silva MG, Ramesh KT (1997) Mater Sci Eng A232:11

Li QM, Magkiriadis I, Harrigan JJ (2006) J Cell Plast 42:371

Chan KC, Xie LS (2003) Scr Mater 48:1147

Tzeng S-C, Ma W-P (2007) Int J Adv Manuf Technol 32:473

Paul A, Ramamurty U (2000) Mater Sci Eng A 281:1

Firstov SA, Podrezov YN, Lugovoi NI, Slyunyaev VN, Verbilo DG (2000) Powder Metall Met Ceram 39:407

Acknowledgements

The authors would like to thank the Scientific Research Commission of Anadolu University for financing this work under the contract number of 040231.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tuncer, N., Arslan, G. Designing compressive properties of titanium foams. J Mater Sci 44, 1477–1484 (2009). https://doi.org/10.1007/s10853-008-3167-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3167-z