Abstract

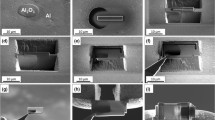

Thermally sprayed ceramic coatings such as plasma-sprayed alumina exhibit a composite microstructure actually due to the presence of defects such as pores, inter-lamellar and intra-lamellar cracks. These second phase-typed features influence the mechanical behaviour of the coating dramatically. In this study, a microstructure simulation of plasma-sprayed alumina was developed for the optimizing of component properties such as electrical tool used in the oil industry. This approach consisted of a finite-element analysis of mechanical properties from simulated microstructures. Several composite microstructures were tested from air plasma spraying of alumina. Various degrees of porosity and cracks could be obtained from different spraying conditions. Every composite microstructure was studied using a quantitative image analysis of scanning electron microscope (SEM) cross-sections. A finite-element model based on the actual microstructure was developed. First, two-dimensional (2D) finite elements meshes were created from SEM images of microstructures. Then, in order to have a realistic representation of the three-dimensional (3D) microstructure, pictures were obtained using X-ray microtomography. Volume tetrahedral grids were generated to simulate the properties of alumina coatings. This work studies the contribution of every part of the alumina coating to the final properties and shows potentials and limitations of the 2D and 3D computational approach.

Similar content being viewed by others

References

Gadow R, Killinger A, Voss A, Friedrich C (1998) Proceedings of the 15th international thermal spray conference, Nice, p 1083

Pawlowski L (1988) Surf Coat Technol 35:285

Beauvais S, Guipont V, Jeandin M, Juve D, Treheux D, Robisson A, Saenger R (2005) J Electroceramics 15:65

Li CJ, Ohmori A (2002) J Therm Spray Technol 11:365

Beauvais S, Guipont V, Borit F, Jeandin M, Espagnol M, Khor KA, Robisson A, Saenger R (2004) Surf Surf Coat Technol 183:201

Sarikaya O (2005) Surf Coat Technol 190:388

Bolelli G, Cannillo V, Lusvarghi L, Manfredini T, Montorsi M (2005) Surf Coat Technol 201:474

Wang Z, Kulkarni A, Deshpande S, Nakamuri T, Herman H (2003) Acta Mater 51:5319

Sevostianov I, Kachanov M (2001) Mater Sci Eng A 297:235

Kulkarni A, Goland A, Herman H, Allen A, Ilavsky J, Long G, De Carlo F (2005) J Therm Spray Technol 14:239

Madi K, Forest S, Boussuge M, Gailliegue S, Lataste E, Buffiere JY, Bernard D, Jeulin D (2007) Comput Mater Sci 39:224

Michlik P, Berndt CC (2006) Surf Coat Technol 201:2369

Feldkamp LA, Davis LC, Kress JW (1984) J Opt Soc Am 6:612

Ctibor P, Bohac P, Stranyanek M, Ctyrtlik R (2006) J Eur Ceramic Soc 26:3509

Boch P, Gault C, Platon F (1983) In: Vincenzini P (ed) Proceedings of the 5th international meeting on modern ceramics technologies, Lignano Sabbiadoro, p 825

Pharr GM, Olivier WC, Brotzen FR (1992) J Mater Res 7:613

Houdaigui ELF, Forest S, Gourgues AF, Jeulin D (2005) Proceedings of the IUTAM symposium, Beijing, p 171

Damani RJ, Wanner A (2000) J Mater Sci 35:4307

Parra Denis E, Barat C, Jeulin D, Ducottet C (2007) Mat Charact (in press)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Amsellem, O., Madi, K., Borit, F. et al. Two-dimensional (2D) and three-dimensional (3D) analyses of plasma-sprayed alumina microstructures for finite-element simulation of Young’s modulus. J Mater Sci 43, 4091–4098 (2008). https://doi.org/10.1007/s10853-007-2239-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2239-9