Abstract

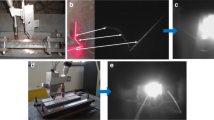

This paper presents a method of autonomously detecting weld seam profiles from molten pool background in metal active gas (MAG) arc welding using a novel model of saliency-based visual attention. First, a vision sensor based on structured light is employed to capture laser stripes and molten pools simultaneously in the same frame. Second, to effectively detect the weld seam profile from molten pool background for next autonomous guidance of initial welding positions and seam tracking, a model of visual attention based on saliency is proposed. With respect to the enhanced effect of saliency, the proposed model is much better than the classic models in the field. According to the comprehensive saliency map created by the proposed model, the weld seam profile can be extracted after threshold segmentation and clustering are applied to it in turn. Third, different weld seam images are used to demonstrate the robustness of the proposed methodology and last, to evaluate the performance of the proposed method, a measure called profile extraction rate (PER) is computed, which shows that the extracted weld seam profile can basically meet the requirements of seam tracking and the guidance of welding torches.

Similar content being viewed by others

References

Drews, P., Starke, G.: Welding in the century of information technology. Wel. World, Le Soudage Dans Le Monde 34, 1–20 (1994)

Trailer: Manufacturer depends on robotic welding to boast production. Weld. J. 74(7), 49–51 (1995)

Pan, J.: A survey of welding sciences in 21th century. In: Proceedings 9th Chinese Welding Conferences, pp 001–017 (1999)

Chen, S., Wu, J.: Intelligentized technology for arc welding dynamic process, p 29. Springer-Verlag, LNEE (2009)

Wei, S., Ma, H., Lin, T., Chen, S.: Autonomous guidance of initial welding position with single camera and double positions method. Sens. Rev. 30(1), 62–68 (2010)

Xu, Y., Zhong, J., Ding, M., Chen, H., Chen, S.: The acquisition and processing of real-time information for height tracking of robotic GTAW process by arc sensor. Int. J. Adv. Manuf. Technol. 65(5-8), 1031–1043 (2013)

Ye, Z., Fang, G., Chen, S., Zou, J.: Passive vision based seam tracking system for pulse-MAG welding. Int. J. Adv. Manuf. Technol. 67(9-12), 1987–1996 (2013)

Fernandez, V., Acevedo, R., Alvarez, A.E., Lopez, A., Garcia, D., Fernandez, R., Meana, M., Sanchez, J.: Low-cost system for weld tracking based on artificial vision. IEEE Trans. Ind. Appl. 47(3), 1159–1167 (2011)

Yu, H., Xu, Y., Lv, N., Chen, H., Chen, S.: Arc spectral processing technique with its application to wire feed monitoring in Al–Mg alloy pulsed gas tungsten arc welding. J. Mater. Process. Technol. 213(5), 707–716 (2013)

Zhang, Z., Yu, H., Lv, N., Chen, S.: Real-time defect detection in pulsed GTAW of Al alloys through on-line spectroscopy. J. Mater. Process. Technol. 213(7), 1146–1156 (2013)

Lv, N., Xu, Y., Zhang, Z., Wang, J., Chen, B., Chen, S.: Audio sensing and modeling of arc dynamic characteristic during pulsed al alloy GTAW process. Sens. Rev. 33(2), 141–156 (2013)

Gao, F., Wang, K.: The Research of Classification Method of Arc Welding Pool Image Based on Invariant Moments. In: Power Engineering and Automation Conference (PEAM), pp 73–76. IEEE, Wuhan, China (2011)

Wu, M., Wei, L., Xiao, L., Yu, S.: Extract the aluminum alloy MIG welding pool edge with Otsu threshold selection based on the genetic algorithmic. In: Information Science and Engineering (ICISE), 2nd International Conference on, pp 1173–1175 . IEEE, Hangzhou, China (2010)

Zhang, Y., Gao, X.: Analysis of characteristics of molten pool using cast shadow during high-power disk laser welding. Int. J. Adv. Manuf. Technol. 70(9-12), 1979–1988 (2014)

Chen, Z., Gao, X.: Detection of weld pool width using infrared imaging during high-power fiber laser welding of type 304 austenitic stainless steel. Int. J. Adv. Manuf. Technol. 74(9-12), 1247–1254 (2014)

Chen, B., Wang, J., Chen, S.: A study on applications of multi-sensor fusion in pulsed GTAW. Indust. Robot: Int. J. 37(2), 168–176 (2010)

Moon, H., Kim, Y., Beattie, R.: Multi sensor data fusion for improving performance and reliability of fully automatic welding system. Int. J. Adv. Manuf. Technol. 28(3–4), 286–293 (2006)

Gu, W., Xiong, Z., Wan, W.: Autonomous seam acquisition and tracking system for multi-pass welding based on vision sensor. Int. J. Adv. Manuf. Technol. 69(1–4), 451–460 (2013)

Liu, X., Wang, G., Shi, Y.: Image processing of welding seam based on single–stripe laser vision system. In: Proceedings 6th International Conference Intelligent Systems Design and Applications, vol. 2, pp 463–470 (2006)

Fang, Z., Xu, D., Tan, M.: A vision-based self-tuning fuzzy controller for fillet weld seam tracking. IEEE/ASME Trans. Mechatron. 16(3), 540–550 (2011)

Itti, L., Koch, C., Niebur, E.: A model of saliency-based visual attention for rapid scene analysis. IEEE Trans. Patt. Anal. Mach. Intell. 20(11), 1254–1259 (1998)

Harel, J., Koch, C., Perona, P.: Graph-based visual saliency. In: Proceedings 19th International Conference Advances in Neural Information Processing Systems, pp 545–552 (2006)

Hou, X., Harel, J., Koch, C.: Image signature: highlighting sparse salient regions. IEEE Trans. Pattern Anal. Mach. Intell. 34(1), 194–201 (2012)

Fang, Y., Lin, W., Lau, C., Lee, B.: A visual attention model combing top-down and bottom-up mechanisms for salient object detection. In: Proceedings IEEE Acoustics Speech and Signal Processing (ICASSP) Conference, pp 1293–1296 (2011)

Wu, B., Xue, T., Zhang, T, Ye, S.: A novel method for round steel measurement with a multi-line structured light vision sensor. Meas. Sci. Technol. 21(2), 025204 (2010)

Li, Y., Li, Y., Wang, Q., Xu, D.: Measurement and defect detection of the weld bead based on online vision inspection. IEEE Trans. Instrum. Meas. 59(7), 1841–1849 (2010)

Li, Z., Wang, W., Wang, X., Li, H.: Analysis of laser-MAG hybrid welding coupling mechanism based on spectrum. J. Mech. Eng. 46(8), 62–67 (2010)

Autio, I., Elomaa, T.: Flexible view recognition for indoor navigation based on Gabor filters and support vector machines. Pattern Recognit. 36(12), 2769–2779 (2003)

Bianconi, F., Fernándezb, A.: Evaluation of the effects of Gabor filter parameters on texture classification. Pattern Recognit. 40(12), 3325–3335 (2007)

Yang, M., Zhang, L., Shiu, S., Zhang, D.: Gabor feature based robust representation and classification for face recognition with Gabor occlusion dictionary. Pattern Recognit. 46(7), 1865–1878 (2013)

Zhang, Q., Liu, H., Shen, J., Gu, G.: An improved computational approach for salient region detection. J. Comput. 5(7), 1011–1018 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, Y., Chen, Y., Xu, Y. et al. Autonomous Detection of Weld Seam Profiles via a Model of Saliency-Based Visual Attention for Robotic Arc Welding. J Intell Robot Syst 81, 395–406 (2016). https://doi.org/10.1007/s10846-015-0226-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10846-015-0226-y