Abstract

Kinetics of the cross aldol condensation of valeraldehyde with cyclopentanone was investigated in a batch reactor under atmospheric pressure at 130 °C using heterogeneous metal modified oxides, such as CeO2–MgO, FeO–MgO, FeO–CaO as well as pristine CaO as catalysts. The catalysts were prepared either by evaporation impregnation or deposition precipitation methods and characterized by XRD, TEM, SEM, nitrogen adsorption, ammonia and CO2 TPD. The results revealed that an optimum amount of strong basic sites gives the highest ratio between cross condensation and self-condensation products of valeraldehyde. The highest yield of the desired product 2-pentylidenecyclopentanone (66%) was obtained with FeO–MgO prepared by the deposition precipitation methods.

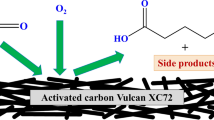

Graphical Abstract

Cross-condensation of valeraldehyde with cyclopentanone was investigated over heterogeneous Fe–CaO, CeO–MgO, FeO–CaO and CaO catalysts at 130 °C using cyclopentanone as a solvent and reactant. The highest yield of the desired product, 2-pentylidene-cyclopentanone, finding applications as fragrances, flavours and pharmaceuticals, was 66% obtained over FeO–MgO catalyst exhibiting both acid and basic sites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Several reactions are catalyzed by homogeneous and heterogeneous bases, including aldol condensation [1,2,3,4] and transesterification for product of biodiesel [5]. Aldol condensation is used for synthesis of various products ranging from basic and specialty chemicals to fragrances, flavours and pharmaceuticals [1,2,3,4,5]. Conventionally aldol condensation is performed using homogeneous catalysts [6, 7], such as sodium or potassium hydroxide or Ti(O-t-Bu)4 as catalysts [7]. Aldol condensation of isophorone was recently demonstrated with furanic aldehydes using NaOH as a catalyst for production of jet fuels [4]. Heterogeneous catalysts could facilitate a more environmentally benign way to produce chemicals, as for example in alkaline earth metal-transition metal oxide in biodiesel production [5], or in aldol condensation due to their easy separation and reuse.

Very often heterogeneous base catalysts are also quite cheap, such as aluminophosphate [1] and hydrotalcites [2], active in synthesis of 2-pentylidenecyclopentanone. In this work cross-condensation of valeraldehyde with cyclopentanone was investigated over several heterogeneous catalysts of basic nature, such as Ce–MgO, CaO and Fe-modified CaO and MgO. The aim was to study the influence of the type of base supports and methods of catalyst synthesis on the physico-chemical and catalytic properties in cross-condensation of valeraldehyde with cyclopentanone.

Besides cross-condensation per se several reactions (Fig. 1) can also occur, i.e. self-condensation of both valeraldehyde and cyclopentanone (Fig. S1) [4, 5]. In cross aldol condensation the first step is formation of hydroxylated 1-hydroxy-2-pentylcyclopentanone 3, which in the consecutive step undergoes dehydration forming an unsaturated ketone, 2-pentylidenecyclopentanone 4. This ketone being the desired product, can further react with another aldehyde forming 2,5-dipentylidenecyclopentanone 7.

Cross-aldol condensation of valeraldehyde with cyclopentanone has been very scarcely studied over heterogeneous catalysts [1, 2]. The desired product 4, 2-pentylidenecyclopentanone has been synthesized over heterogeneous hydrotalcites as catalysts giving maximally 90% yield using valeraldehyde to cyclopentanone molar ratio of 1:5 at 80 °C after 11 h via slowly adding valeraldehyde into the reactor containing cyclopentanone [2]. In another work also an excess of cyclopentanone was used in comparison with valeraldehyde in m-xylene as a solvent at 130 °C under nitrogen [1]. The highest selectivity of 2-pentylidenecyclopentanone, 91% at 31% conversion, was obtained at 130 °C after 2 h using amorphous aluminosilicate as a catalyst.

Other reactions relevant to aldol condensation, namely self-condensation of cyclopentanone and valeraldehyde, have been also investigated. Self-condensation of cyclopentanone gives 2-cyclopentylidene-cyclopentanone, which finds applications as fuel or in hydrogenated form as fragrances and flavors [8, 9]. This reaction occurs using potassium hydroxide as a catalyst, for example at 100 °C [8], followed by extraction with diethylether, washing and drying finally giving 73% yield. More recently also heterogeneous catalysts have been used in the synthesis of 2-cyclopentylidene-cyclopentanone by self-condensation of cyclopentanone [10]. Mesoporous MgO–ZrO2 gave two main products, namely 2-cyclopentylidene-cyclopentanone composed of 10 carbon atoms and 2,5-dicyclopentylidene-cyclopentanone [10]. A remarkable excess of the former product with 100% selectivity was obtained after 4.5 h at 8% conversion using a lower reaction temperature 110 °C. On the contrary at 130 °C selectivity was 92% at 85% conversion. The same reaction was also investigated with MOF encapsulated phosphotungstic acid as a catalyst at 130 °C under nitrogen [11]. The yield of 2-cyclopentylidene-cyclopentanone was only ca. 12% after 2 h because of its further transformation to trimeric compounds and after removal of hydrogen to trindane.

Self-condensation of valeraldehyde gives 2-propylhept-2-enal, which has found applications as an intermediate for production of parfumes [12], and plasticizers [13, 14]. Aqueous NaOH is typically applied as a catalyst in industrial scale for this reaction. It was pointed out [13], that this process causes corrosion and exhibits poor product selectivity. TiO2 was confirmed to be an efficient heterogeneous catalyst for synthesis of 2-propylhept-2-enal giving very high selectivities to the desired product at 190 °C [13]. Zhao et al. [13] stated that acidity is also required for production of 2-propylhept-2-enal.

In the current work metal oxides have been applied as catalysts in aldol condensation of valeraldehyde with cyclopentanone. Since it is known that aldol condensation requires acids or bases as catalysts [15], basic supports such as CaO and MgO were modified with ceria and iron oxide, because of amphoteric nature of ceria and Lewis acidity of iron oxide. Therefore, not surprisingly, iron oxides have been used as catalysts in cyclohexanone aldol condensation [16], while cesium was utilized in aldol condensation of heptanal with benzaldehyde [17]. The aim in this work was to reveal the role of basic and acid active sites, metal functions in aldol condensation of valeraldehyde with cyclopentanone and investigate reaction kinetics and thermodynamics. The acidity and basicity of the catalysts were quantified by NH3 and CO2 temperature programmed desorption techniques. According to our knowledge this is the first time when kinetics and thermodynamics of valeraldehyde–cyclopentanone aldol condensation are reported.

2 Experimental Section

2.1 Catalyst Synthesis

Fe-modified MgO and CaO and Ce-modified MgO catalysts were prepared using deposition precipitation (DP) and evaporation impregnation (EIM) methods. The CeO2–MgO–DP catalyst was prepared via dissolving cerium nitrate in distilled water adding thereafter MgO into the cerium nitrate aqueous solution. In the deposition–precipitation procedure, pH was first increased to 10 with ammonium hydroxide solution (25%) to precipitate cerium followed by stirring the slurry at 150 rpm for 24 h. After that, the catalyst was filtered and washed with distilled water. CeO2–MgO–DP catalyst was dried in an oven at 100 °C for 7 h. Decomposition of cerium nitrate was carried out by thermal treatment of CeO2–MgO–DP catalyst in a muffle oven using a step calcination procedure. The catalyst designated as CeO2–MgO–DP.

FeO–MgO–DP catalyst was prepared using aqueous solution of ferric nitrate by a deposition precipitation method. The pH was increased to 10 using ammonium hydroxide solution (25%) and the synthesis carried out for 24 h, which was followed by drying at 100 °C for 7 h and calcination in a muffle oven. The catalyst designated as Fe–MgO–DP.

The aqueous solution of the ferric nitrate precursor was mixed with CaO and kept in a rotary evaporator for 24 h at the stirring speed of 50 rpm. In the subsequent step, the water phase was evaporated. The catalyst was removed from the rotatory flask and dried in an oven at 100 °C for 7 h. Decomposition of cerium nitrate was carried out in a muffle oven at 450 °C for 4 h using a step calcination procedure. The catalyst was designated as Fe–CaO–EIM.

2.2 Catalyst Characterization Methods

The Philips X’Pert Pro MPD X-ray powder diffractometer was used in the XRD measurements. The diffractometer was operated in Bragg–Brentano diffraction mode, and the monochromatized Cu–Kα radiation (λ = 1.541874 Å) was generated with a voltage of 40 kV and a current of 45 mA. The measured diffractograms were analyzed with Philips X’Pert HighScore and MAUD [18] programs. The Powder Diffraction File 2 (PDF-2) database, Inorganic Crystal Structure Database (ICSD), and Crystallography Open Database (COD) were used as references [19,20,21].

The scanning electron microscopy coupled with an energy dispersive X-ray analyzer was utilized to study morphology of the fresh catalysts using Zeiss Leo Gemini 1530 microscope combined with secondary electron and backscattered electron detectors. Acceleration voltage of 15 kV was used for X-ray analyzer. In order to perform analysis, the catalyst was placed as a thin layer on top of the carbon coating to enhance the conductivity and allow high quality of magnified images.

The transmission electron microscopy was utilized to study the structural properties, porosity, metal particle size and distribution using JEM-1400Plus (by JEOL ltd. Japan) of 120 kV maximal acceleration voltage. Interpretation of TEM images and determination of the particles sizes of the fresh and spent catalyst were done using ImageJ program.

The specific surface area was determined with Sorptometer 1900 (Carlo Erba Instrument) using nitrogen physisorption. The catalysts were outgassed at 150 °C for 3 h prior to the measurement. The BET equation was used to calculate the specific surface area.

CO2 TPD measurements were performed to determine the concentration of basic sites using Autochem 2010, Micromeritics instrument. The catalyst, 200 mg, was first dried at 150 °C for 30 min under helium (AGA, 99.996%) after which it was cooled to 100 °C. Thereafter CO2 (AGA) was adsorbed on the catalyst surface during 30 min. The physisorbed CO2 was flushed from the catalyst surface at 100 °C for 30 min after which the temperature was increased by 10 °C/min up to 700 °C.

Ammonia TPD was performed with Micromeritics (AutoChem 2910) using helium as a carrier gas. The sample was dried prior to the measurement at 250 °C for 30 min after which ammonia (5 vol% in helium, AGA) was adsorbed on the catalyst for 60 min at 25 °C. Then the gas supply was stopped and these conditions were hold for 30 min. In the next step the temperature was increased by 10oC/min to 100 °C and hold at 100 °C for 30 min. The ammonia TPD was measured using the following temperature programme: 100 °C–10 °C/min–600 °C.

2.3 Kinetic Experiments

Catalytic experiments were typically performed under flowing helium at 130 °C in a glass reactor equipped with a stirrer. Typically valeraldehyde (Aldrich, 97%) was reacting with an excess of cyclopentanone (Sigma Aldrich, > 99%), which was also applied as a solvent (60 ml), if not otherwise stated. The initial valeraldehyde concentration was 0.50 mol/l if not specifically mentioned. The experiments were performed by adding valeraldehyde, cyclopentanone and the catalyst into the cold reactor, which was then heated to 130 °C. The reactor system was equipped with a condenser, which exhibited temperature close to zero. Valeraldehyde and a part of cyclohexanone were thus condensed back to the liquid phase. The experiments were carried out under argon atmosphere. The weight ratio of valeraldehyde to cyclopentanone in the kinetic experiments was 0.05, while the amount of catalyst was 1.6 g. The mass ratio of valeraldehyde to catalyst was 1.7 being the same as was used in [1]. Small catalyst particles (below 63 µm) were used under vigorous stirring (600 rpm) to avoid internal and external mass transfer limitations. In some experiments mesitylene (Sigma Aldrich, 97%) was used as a solvent. The products were analyzed by a GC equipped with HP-5 column (30 m, di=320 µm, film thickness 0.5 µm) using the following temperature programme: 60 °C (2 min)–8 °C/min–124 °C–4 °C/min–200 °C–12 °C/min–280 °C (10 min). The reaction products were identified by GC–MS (Agilent Technologies, 6870N) equipped with DB-1 column (30 m, 250 µm, film thickness 0.50 µm).

3 Results and Discussion

3.1 Catalyst Characterization Results

XRD results revealed that FeO–CaO–EIM catalyst contained iron only as Ca2Fe2O5 phase (Table 1; Fig. 2). Ca2Fe2O5 in [22] was prepared by coprecipitation of Ca and Fe nitrates and calcined at 500 °C. The size of Ca2Fe2O5 is about 60 nm based on XRD [23]. On the other hand, metal oxide Fe2O3 particles are threefold smaller than Ca2Fe2O5 (Table 1). XRD results of CeO2–MgO showed the presence of cubic CeO2 [24] and MgO [28] (Table 2). XRD of FeO-MgO-DP displayed only the presence of cubic MgO. This result indicates that iron either is in an amorphous form or it well dispersed on the support with the particle size below 3 nm, not being detectable by XRD.

SEM images of different catalysts are depicted in Fig. 3. CeO2–DP exhibits both spherical and plate-like character (Fig. 3a). FeO–MgO–DP contains plates (Fig. 3b) whereas FeO–CaO–EIM exhibited large spherical particles between 105 and 148 nm (Fig. 3c). Particles in FeO–CaO–EIM were both of irregular and spherical shapes in the range of 50 to 600 nm (Fig. 3d). The particle sizes in CaO varied in a broader range of 50 to 400 nm. These changes can be related to the presence of different phases in these materials. CaO is rich in hexagonal Ca(OH)2, however, FeO–CaO–EIM contained mainly CaCO3.

The TEM images showed also large differences in the particle sizes and shapes (Fig. 4). FeO–CaO–EIM contains spherical particles (Fig. 4a), whereas the parent CaO exhibited 10 to 50 nm particles which were not easy to separate from each other.

Basicity determined by CO2 temperature programmed desorption showed that pure CaO exhibited the highest basicity in accordance with the literature (Table 3; Fig. 5a) [23, 29]. CaO contained large amounts of medium and strong acid sites. When CaO was modified by Fe using the evaporation impregnation method its basicity decreased to 59% of the initial value for pristine CaO due to a relatively high Fe loading, 10%. In addition the concentration of strong basic sites decreased in this catalyst by iron modification being only 21% of that of CaO. Nevertheless, basicity of FeO–CaO–EIM was quite high, partially due to high basicity of Ca2Fe2O5 (Fig. 5a) [5], which was comparative to the parent CaO. The composite material CeO2–MgO–DP with 24 wt% Ce exhibited a total basicity higher than the pristine MgO. The amount of strong basic sites in both CeO2–MgO–DP was, however, quite low compared to the parent MgO, which according to the literature exhibits more strong basic sites than CeO2 [30].

Acidity, determined by ammonia TPD, follows the order (Table 3; Fig. 5 b): 21 wt% CeO2–MgO–DP > 10 wt% FeO–CaO–EIM > 7 wt% FeO–MgO–DP. The lowest acidity was measured for FeO–MgO–DP, containing the lowest metal amount. In fact for this material no Fe2O3 was observed according to XRD (Table 2) and most probable iron is present in the form of finely dispersed iron oxide particles. Results in Table 3 showing some acidity for FeO–MgO–DP can be interpreted by taking into account that Fe2O3 exhibits both Brønsted and Lewis acidity [31]. The highest acidity of CeO2–MgO–DP is explained by its high CeO2 loading. It is known that CeO2 is amphoteric which influences its acidic and basic properties. Acidity of 10 wt% FeO–CaO–EIM is related to presence of iron + 3 possessing Lewis acidity [32] in the form of Ca2Fe2O5.

3.2 Reaction Network and Thermodynamic Analysis

The reaction network for aldol condensation of valeraldehyde with cyclopentanone is shown in Fig. 1. It should be pointed out here, that as mentioned in the Introduction self-condensation of cyclopentanone forming 2-cyclopentylidene-cyclopentanone, requires presence of strong basicity, thus its contribution to valeraldehyde self- and cross-condensation reactions was considered to be less significant. According to the literature [2] valeraldehyde condensation proceeds via formation of an intermediate 1-hydroxy-2-pentylcyclopentanone 3, which is dehydrated forming the desired product 2-pentylidenecyclopentanone 4. In addition to formation of the desired cross-condensation product, the latter can also be isomerized to 2-pentyl-2-cyclopenten-1-one 5, especially at higher temperature, when this isomer is thermodynamically more stable than the desired product 4 [2]. The desired product can also react further with another valeraldehyde molecule giving 2-(1-hydropentyl)-5-pentylidene cyclopentanone 6 and its corresponding dehydrated product, 2,5-dipentylidene cyclopentanone 7. Furthermore, other reactions can also occur, namely self-condensation of valeraldehyde giving 2-propyl-3-hydroxyheptanal, 1 which can be dehydrated to the corresponding unsaturated aldehyde, 2-propylhept-2-enal 2. In the current case no pentyl valerate 8 could be seen, which in general can be formed via the Tischenko reaction.

Aldol condensation can occur both on basic and acid sites according to the literature suggestions [2]. Cross aldol condensation over basic sites can be described by a mechanism, [2] when the base accepts a proton from the ketone forming in the current case negatively charged O− in cyclopentenone which attacks the aldehyde via a nucleophile forming hydroxypentylcyclopentanone. Dehydration occurs via formation of a carbocation which after deprotonation gives 2-pentylidenecyclopentanone.

In acid catalyzed aldol condensation the reaction has been proposed to start with enolization of the aldehyde over Lewis acid sites. Subsequently the carbocation formed from the aldehyde on Brønsted acid site reacts with the enol leading to formation of a cross condensation product [33].

While the main focus in this work was on kinetics of the cross condensation of valeraldehyde with cyclopentanone, in order to understand if thermodynamics governs the overall reaction, first thermodynamic analysis was performed. According to our knowledge thermodynamics for the cross condensation and relevant reactions has not been reported. Evaluation of thermodynamics was done by calculating enthalpy (ΔH0r) and Gibbs free energy (ΔG0r) at standard conditions using the approach from [34] and starting from the standard enthalpy (ΔH0f) and Gibbs free energy (ΔG0f) of formation from the elements estimated with the Joback approach [35,36,37]:

The equilibrium constant of each reaction was calculated from its definition

The dependence of the reaction free Gibbs energy on temperature was included by implementing the Gibbs–Helmholtz equation valid at P = 1 bar (ΔGΦr,j)

The calculated enthalpy and Gibbs free energy formation for each component (i) are reported in Table 4. Numbering of reactions is from Fig. 1.

Starting from these values, the enthalpy and Gibbs free energy for each reaction (j) at standard conditions, equilibrium constants at standard conditions (K0j), enthalpy and Gibbs free energy at different temperatures and pressure were calculated. A temperature range between Tmin=353.15 K and Tmax=423.15 K was investigated. It can be seen that thermodynamically most favorable reactions are 4 and 7, namely dehydration of the intermediate 2-hydroxyl-2-pentylcyclopentanone to the desired product and formation of 2,5-dipentylidene cyclopentanone (Table 5; Fig. 6). It can also be seen from Fig. 6 that both of these reactions become even more thermodynamically feasible at higher temperatures. Interestingly the ∆G for formation of 2-pentyl-2-cyclopentyl-1-one, isomer of the desired product, was independent on temperature.

3.3 Catalytic Results

In the preliminary work valeraldehyde condensation with cyclopentanone was investigated using mesitylene as a solvent, since in [1] successful aldol condensation in this reaction was reported to occur in another substituted aromatic compound, o-xylene, as a solvent. In the current work aldol condensation of valeraldehyde with cyclopentanone was performed analogously to the work of Hasni et al. [1] using 1:5 molar ratio of the reactants, however, instead of m-xylene in mesitylene as a solvent over CeO2–MgO–DP. The results showed, however, that with a low initial valeraldehyde concentration (0.09 mol/l) in mesitylene as a solvent, mainly self-condensation products of valeraldehyde (98%) were formed in 3 h at 56% conversion at 130 °C, when 1:5 molar ratio of valeraldehyde to cyclopentanone was applied. In addition, minor oxidation of mesitylene occurred resulting in formation of 3,5-dimethylbenzaldehyde, confirmed by GC–MS, which might be possible by lattice oxygen originating from CeO2. After the initial experiments in mesitylene as a solvent, valeraldehyde condensation was subsequently performed using cyclopentanone both as a solvent and a reactant.

Both the thermal reaction between valeraldehyde and cyclohexanone in the absence of any catalyst as well as catalytic experiments were carried out using an excess of cyclopentanone. The concentration profiles for valeraldehyde and its self- and cross-condensation products are shown in Figs. 7, 8, 9, 10, 11, 12. In thermal cross condensation of valeraldehyde at the initial concentration of 0.53 mol/l 95% conversion of valeraldehyde was obtained. The main product was 2-propylhept-2-enal. In addition relative large amounts of both 2-propyl-3-hydroxyheptanal, identified based on the confirmation of the m/z + peak at 173 in GC–MS analysis reported in [38] and 1-hydroxy-2-pentylcyclopentanone and an isomer of the desired 2-pentyl-2-cyclopent-1-one were formed. This result clearly shows that valeraldehyde self-condensation does not require any catalyst under the studied conditions. In addition the isomerization of the desired product, 2-pentylidenecyclopentanone can occur, especially at relatively high temperatures due to the fact that 2-cyclopent-1-one 5 is thermodynamically more stable than 4 due to the presence of a conjugated double bonds, i.e. a carbonyl bond and a cyclic olefinic bond and high temperatures favor isomerization [2]. The sum of the reactant and product concentrations was close to 100%. Since thermal aldol condensation of valeraldehyde–cyclopentanone showed promising results, it was worth to investigate the performance of catalysts at the same conditions. Valeraldehyde self-condensation is a thermodynamically feasible reaction even if approximate calculations of the Gibbs free energy for formation of the intermediate 2-propyl-3-hydroxyheptanal, gave a positive value.

Concentration of valeraldehyde and its self- and cross-condensation products as a function of time in valeraldehyde cross-condensation with cyclopentanone. The initial valeraldehyde concentration was 0.53 mol/l in cyclohexane. The experiments were performed at 130 °C under argon flow. Symbols: valeraldehyde (white square), 2-pentylidenecyclopentanone 4 (black circle), 2-pentyl-2-cyclopent-1-one 5 (white circle), 2-propyl-3-hydroxyheptanal (+) 1, 2-propylhept-2-enal (black up-pointing triangle) 2 and 1-hydroxy-2-pentylcyclopentanone (black square) 3

Concentration of valeraldehyde and its self- and cross-condensation products as a function of time in valeraldehyde cross-condensation with cyclopentanone over FeO–CaO–EIM. The initial valeraldehyde concentration was 0.53 mol/l in cyclohexane. The experiments were performed at 130 °C under argon flow. Symbols: valeraldehyde (white square), 2-pentylidenecyclopentanone 4 (black circle), 2-pentyl-2-cyclopent-1-one 5 (white circle), 2-propyl-3-hydroxyheptanal (+) 1, 2-propylhept-2-enal (black up-pointing triangle) 2 and 1-hydroxy-2-pentylcyclopentanone (black square) 3

Concentration of valeraldehyde and its self- and cross-condensation products as a function of time in valeraldehyde cross-condensation with cyclopentanone over FeO–MgO–DP. The initial valeraldehyde concentration was 0.53 mol/l in cyclohexane. The experiments were performed at 130 °C under argon flow. Symbols: valeraldehyde (white square), 2-pentylidenecyclopentanone 4 (black circle), 2-pentyl-2-cyclopent-1-one 5 (white circle), 2-propyl-3-hydroxyheptanal (+) 1, 2-propylhept-2-enal (black up-pointing triangle) 2 and 1-hydroxy-2-pentylcyclopentanone (black square) 3

Concentration of valeraldehyde and its self- and cross-condensation products as a function of time in valeraldehyde cross-condensation with cyclopentanone over CeO2–MgO–DP. The initial valeraldehyde concentration was 0.53 mol/l in cyclohexane. The experiments were performed at 130 °C under argon flow. Symbols: valeraldehyde (white square), 2-pentylidenecyclopentanone 4 (black circle), 2-pentyl-2-cyclopent-1-one 5 (white circle), 2-propyl-3-hydroxyheptanal (+) 1, 2-propylhept-2-enal (black up-pointing triangle) 2 and 1-hydroxy-2-pentylcyclopentanone (black square) 3

Concentration of valeraldehyde and its self- and cross-condensation products as a function of time in valeraldehyde cross-condensation with cyclopentanone over CaO. The initial valeraldehyde concentration was 0.53 mol/l in cyclohexane. The experiments were performed at 130 °C under argon flow. Symbols: valeraldehyde (white square), 2-pentylidenecyclopentanone 4 (black circle), 2-pentyl-2-cyclopent-1-one 5 (white circle), 2-propyl-3-hydroxyheptanal (+) 1, 2-propylhept-2-enal (black up-pointing triangle) 2 and 1-hydroxy-2-pentylcyclopentanone (black square) 3

Catalytic cross-condensation of valeraldehyde with cylopentanone was investigated over two different FeO catalysts supported on MgO and CaO as well as CaO per se and CeO2–MgO–DP (Table 6; Figs. 7, 8, 9, 10, 11, 12). The initial rates for valeraldehyde transformation decreased in the following order: FeO–MgO–DP > CeO2–MgO–DP > FeO–CaO–EIM > CaO (Table 6). This order shows that the catalysts with the lowest basicity exhibited also the lowest initial valeraldehyde transformation rate, apart from a highly basic CaO. This could be explained by initial poisoning of CaO by traces of water and CO2 despite drying over night at 100 °C in an oven. Based on the literature [39] dehydration of the basic catalysts is required to remove adsorbed water and CO2. It is believed that this type of poisoning could easily occur for very basic CaO even in few minutes when loading the catalyst into the reactor. In addition when comparing the converted amounts of valeraldehyde after 120 min obtained with CaO (Fig. 12) and FeO–CaO–EIM (Fig. 11), it can be seen that for neat CaO the conversion was only 83% compared with 99% obtained by FeO–CaO–EIM showing also that addition of just 10 wt% FeO increased activity of CaO.

Comparison of conversion levels over different catalysts shows that CaO, FeO–CaO–EIM and CeO2–MgO–DP with strong basicity efficiently converted valeraldehyde. The conversion levels increased also with the increasing amount of strong basic sites (Fig. 8). The sums of the liquid phase products determined by GC (GCLPA) were high with FeO–MgO–DP and FeO–CaO–EIM, whereas CaO despite its high basicity exhibited a lower sum of reactant and product masses determined by GC analysis of the liquid phase. These results may be related to formation of oligomers, in the latter case not visible in GC.

A comparison of the total concentration, i.e. the sum of the reactant and product concentrations from valeraldehyde self- and cross-condensation in the liquid phase, which are visible in GC analysis, as a function of conversion is shown in Fig. 13. The initial concentration of valeraldehyde was 0.53 mol/l and as it can be seen the highest total concentration is obtained in the absence of catalyst being after 3 h. In addition the total concentration increased with increasing conversion for those catalysts which were relatively good for catalyzing the formation of the desired product 4, i.e. FeO–CaO–EIM, FeO–MgO–DP and CaO. It can also be seen from Fig. 13 that the lowest total concentrations were obtained with CeO–MgO–DP and FeO–CaO–DP. The latter catalyst exhibited a very high concentration of acid sites most probably promoting oligomerisation.

A comparison of the total concentration, i.e. the sum of reactant and product concentrations from valeraldehyde self- and cross-condensation in the liquid phase, which are visible in GC analysis, as a function of conversion. The initial valeraldehyde concentration was 0.53 mol/l in cyclohexane. The experiments were performed at 130 °C under argon flow

Selectivity in the cross-condensation of valeraldehyde with cyclopentanone in comparison with valeraldehyde self-condensation can be evaluated by considering the ratio of the cross-condensation to valeraldehyde self-condensation products for thermal and catalytic experiments (Table 6) showing that this ratio was very low for the thermal reaction and reasonably high for catalytic experiments with basic catalysts. The yields of the desired product 4 and self-condensation product of valeraldehyde 2 over different catalysts after 4 h reaction illustrate that the highest yield of the desired product was obtained over FeO–MgO–DP followed by CaO and FeO–CaO–EIM (Table 6; Figs. 9, 10, 12). Repeatability in the cross condensation reactions was adequate showing for FeO–CaO–EIM catalyst minor deviations in the yield of the desired product 4, 42 ± 3%. All these catalysts exhibited strong basicity (Table 3). Intensive 2-propylhept-2-enal formation occurred only in the absence of heterogeneous catalysts. This result is in accordance with [1] where it was concluded that formation of 2-propylhept-2-enal was the lowest with MgO and Al2O3–SiO2, having acid-base site pairs.

The isomer of the desired product (e.g. compound 5) was formed mainly over FeO-MgO-DP as well as over CaO and FeO–CaO–EIM showing that double bond migration occurs not only on acidic, but also on basic sites. According to ammonia TPD FeO–CaO–EIM, in which the iron containing phase is Ca2Fe2O5, is also acidic promoting formation of the desired product isomer (Table 3; Fig. 9). When acidity of CeO2–MgO–DP was lower, subsequently lower amounts of 2-hydroxy-2-pentylcyclopentanone were formed (Table 6, entry 2) compared to FeO–CaO–EIM (Table 6, entry 4).

Noteworthy is also that valeraldehyde self-condensation to form 2-propylhept-2-enal was concluded to be more acid catalyzed, when it was investigated [11] over a more acidic TiO2 catalyst. In this work, however, self-condensation with a relatively highly acidic FeO–CaO–EIM was not able to produce high amounts of 2-propylhept-2-enal. In addition, activity of FeO–CaO–EIM catalyst was decreased after 60 min since dehydration of 2-hydroxy-2-pentylcyclopentanone to the desired product was inhibited (Fig. 9).

Only traces of 2,5-dipentylidene cyclopentanone 7 were formed despite its negative Gibbs free energy. This result indicates that consecutive condensation was retarded. Furthermore, all valeraldehyde has reacted after 120 min over FeO–MgO–DP, when the concentration of 2-pentylidenecyclopentanone was high indicating that valeraldehyde reacted already to some heavy compounds before that, since the GCLPA was 92%.

Esterification of valeraldehyde via the Tischenko reaction forming pentyl valerate 8 was not observed in this work in line with the thermodynamic calculations, showing that such reaction is unfeasible in the studied temperature range.

Comparison of the yield of 2-pentylidenecyclopentanone 2 obtained by all catalysts at 4 h reaction time (Fig. 14) shows that an optimum amount of the largest total amount of basic sites is required for production of cross condensation products with the highest yield of 2 generated over FeO–MgO–DP. In [1] the conclusion was reached that either strongly acidic (e.g. Al2O3–SiO2) or base catalysts, (e.g. MgO) are required, rather than bifunctional catalysts.

4 Conclusions

Ce-, Fe-modified CaO, CeO2 and MgO base catalysts were successfully synthesized using deposition–precipitation (DP) and evaporation impregnation methods (EIM). The physico-chemical characterization of the catalysts using TPD–CO2 showed the presence of the largest total amount of basic sites after CaO in FeO–CaO–EIM (1234 µmol/g) followed by CeO–MgO–DP (1087 µmol/g) catalyst. FeO–CaO–EIM catalyst resulted in the highest conversion (100%) of valeraldehyde during cyclopentanone cross-condensation with valeraldehyde. FeO–MgO–DP catalyst synthesized using the deposition precipitation method afforded the highest yield of the desired product 2-pentylidenecyclopentanone (66%), clearly indicating that the method of catalyst synthesis has a tremendous influence on conversion and selectivity to the desired products. Correlation of valeraldehyde conversion with the amount of medium strong basic sites revealed that these sites affect the aldol condensation reaction.

Abbreviations

- K 0 j :

-

Equilibrium constant at standard conditions for reaction j

- n :

-

Moles, mol

- P :

-

Pressure, bar

- P 0 :

-

Standard pressure, bar

- R :

-

Ideal gas constant, J/K/mol

- T :

-

Absolute temperature, K

- T 0 :

-

Absolute standard temperature, K

- ΔG 0 f :

-

Gibbs free energy of formation at standard conditions, J/mol

- ΔG 0 r :

-

Gibbs free energy of reaction at standard conditions, J/mol

- ΔG Φ r,j :

-

Gibbs free energy of reaction at 1 bar and a chosen temperature, J/mol

- ΔH 0 f :

-

Enthalpy of formation at standard conditions, J/mol

- ΔH 0 r :

-

Enthalpy of reaction at standard conditions, J/mol

- ν i,j :

-

Stoichiometric matrix composed by i components and j reactions

References

Hasni M, Prado G, Rouchaud J, Grange P, Devillers M, Delsarte S (2006) J Mol Catal A Chem 247:116–123

Xu J, Cao Y, Ma Q, Peng X (2013) Asian J Chem 25:3847–3849

Xie J, Zhang L, Zhang X, Han P, Xie J, Pan L, Zou DR, Liu SH, Zou JJ (2018) Sust Energy Fuels 2:1863–1869

Deng Q, Xu J, Han P, Pan L, Wang L, Zhang X, Zou JJ (2016) Fuel Proc Tech 148:361–366

Kwong TL, Yung KF (2015) RSC Adv 5:83748–83756

Mahrwald R, Schick H (1990) Synthesis 7:592–595

Han Z, Yorimitsu H, Hideki S, Hiroshi S, Oshima K (2000) Tetrahedron Lett 41(22):4415–4418C

Martin A (1998) US patent 5776884

Fujisawa H, Kondou Y, US patent (2005) 2005/0009928 A1

Liang D, Li G, Liu Y, Wu J, Zhang X (2016) Catal Comm 81:33–36

Deng Q, Nie G, Pan L, Zou J-J, Zhang X, Wang L (2015) Green Chem 17:4473–4481

Poncet AF (1982) FR patent, 2500477

Zhao L, An H, Zhao X, Wang Y (2016) Ind Eng Chem Res 55:12326–12333

Tang Z, Zhou Y, Feng Y (2004) Appl Catal A Gen 273:171–176

Vrbkova E, Tisler Z, Vyskocilova E, Kadlec D, Cerveny L (2018) Chem Technol Biotech 93:166–173

Vit Z, Nondek L, Malik J (1982) Collect Czech Chem Commun 47:2235–2245

Vrbkova E, Vyskocilova E, Krupka J, Cerveny L (2016) Progr React Kinet Mech 41:289–300

MAUD. http://www.ing.unitn.it/~maud/. Accessed 8 Dec 2018

Powder Diffraction File 2 (PDF-2), sets 1–46, 1996 release, International Centre for Diffraction Data (ICDD)

Inorganic Crystal Structure Database (ICSD) http://www.fiz-karlsruhe.de/icsd.html. Accessed 8 Dec 2018

Crystallography Open Database http://www.crystallography.net/cod/index.php. Accessed 8 Dec 2018

Chesnokov B, Bazhenova L (1985) Zap Vses Mineral O-va 114: 195–196.20. Germany, ICDD Grant-in-Aid

Yang S, Zhang X, Chen L, Sun L, Xie X, Zhao B (2017) J Anal Appl Phys 125:1–8

Morris MC, McMurdie HF, Evans EH, Paretzkin B, Parker HS, Pyrros NP (1983) Standard X-ray Diffraction Powder Patterns, NBS Monograph 25 - Section 20, National Bureau of Standards, p 38

Swanson HE, Tatge E (1953) Natl Bur Stand (US) Circ 539(I):15

Swanson HE, Tatge E (1953) Natl Bur Stand (US) Circ 539(I):15.24

Morris MC, McMurdie HF, Evans EH, Paretzkin B, Parker HS, Panagiotopoulos NC (1981) Standard X-ray Diffraction Powder Patterns, NBS Monograph 25 - Section 18, National Bureau of Standards, p 37

Kern A, Doetzer R, Eysel W (1993) Mineralogisch-Petrographisches Inst., Univ. Heidelberg. Germany, ICDD Grant-in-Aid, (1993)

Yang J, Li N, Li S, Wang W, Wang A, Wang X, Cong Y, Zhang T (2014) Green Chem 16:4879–4884

Ye L, Lin H, Zhou H, Yuan Y (2010) J Phys Chem C 114:19753–19760

Ferretto L, Glisenti A (2002) J Mol Catal A: Chem 187:119–128

Miles WH, Nutaitis CF, Anderton CA (1996) Chem Educ 73:272

Dumitriu E, Hulea V, Fechete I, Auroux A, Lacaze JF, Guimon C (2001) Micropor Mesop Mater 43:341–359

Nemansky MW, Abbott MM, Van Ness HC (1975) Basic engineering thermodynamics. McGraw-Hill, New York

Poling BE, Prausnitz JM, O’Connell JP (2004) The properties of gases and liquids, 5th edn. McGraw-Hill, New York

Joback KG (1984) A unified approach to physical property estimation using multivariate statistical techniques, Thesis SM, Department of Chemical Engineering, Massachusetts Institute of Technology, Cambridge, MA

Joback KG, Reid RC (1987) Chem Eng Comm 57:233–243

Heinz AS, Gonzales JE, Fink MJ, Mitchell BS (2008) J Mol Catal A Chem 304:117–120

Hattori H (1995) Chem Rev 95:537–558

Acknowledgments

Open access funding provided by Abo Akademi University (ABO).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mäki-Arvela, P., Shcherban, N., Lozachmeur, C. et al. Aldol Condensation of Cyclopentanone with Valeraldehyde Over Metal Oxides. Catal Lett 149, 1383–1395 (2019). https://doi.org/10.1007/s10562-019-02701-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02701-1