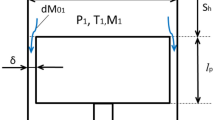

The issue of heat utilization from a displacement compressor of a displacement pump is considered. Analytical dependencies of changes in thermodynamic parameters in the compression and discharge processes in the pump are obtained for the case when heat is supplied from the compressor. The carried out numerical experiment proved that the discharge pressure can be 10 MPa or more in this pump, and the relative supply of fluid to the discharge line can reach up to 1% of the working chamber volume of the pump. It is established that utilization of the gas compression heat in hybrid power machines will improve the efficiency not only of the compressor, but also of the pump.

Similar content being viewed by others

References

P. I. Plastinin, Piston Compressors [in Russian], 1, KolosS, Moscow (2006).

V. E. Shcherba, Workflows of Displacement Compressors [in Russian], Nauka, Moscow (2008).

M. I. Frenkel, Piston Compressors [in Russian], Mashinostroenie, Leningrad (1969).

B. S. Fotin, I. B. Pirumov, I. K. Prilutsky, and P. I. Plastinin, Piston Compressors [in Russian], university textbook, ed. B. S. Fotin, Mashinostroenie, Leningrad (1987).

P. I. Plastinin and V. E. Shcherba, “Workflows of displacement compressors with fluid injection,” Itogi Nauki i Tekhniki. Seriya. Nasosostroenie i Kompressorostroenie. Kholodil’noe Mashinostroenie, Moscow (1996), 154 p.

V. E. Shcherba, A. P. Bolshtyansky, S. Yu. Kaigorodov, and D. A. Kuzeeva, “Analysis of the main advantages of combining compressors and displacement pumps into a single unit,” Vestnik Mashinostroeniya, No. 12, 15–19 (2015).

V. E. Shcherba, A. P. Bolshtyansky, V. V. Shalai, E. V. Khodoreva, Pump-Compressors. Workflows and Design Basics [in Russian], Mashinostroenie, Moscow (2013).

V. E. Shcherba, E. A. Pavlyuchenko, and A. K. Kuzhbanov, “Mathematical modeling of the processes of compression and expansion in a piston pump with a gas damper,” Vestnik Samarskogo Gosudarstvennogo Aerokosmicheskogo Universiteta im. S. P. Koroleva, No. 3 (34), Pt 2, 133–138 (2012).

V. E. Shcherba and I. E. Lobov, “Development and design of a liquid cooling system for a piston compressor based on using gas pressure fluctuations on discharge,” Khim. Neftegaz. Mashinostr., No. 4, 19–24 (2016).

V. E. Shcherba, E. Yu. Nosov, E. A. Pavlyuchenko, et al., “Analysis of fluid dynamics in a piston hybrid power unit with gas volume at suction,” Khim. Neftegaz. Mashinostr., No. 4, 15–19 (2016).

V. E. Shcherba, V. V. Shalai, E. A. Pavlyuchenko, et al., “Thermodynamic foundation for calculating the compression and expansion processes in a displacement pump,” Khim. Neftegaz. Mashinostr., No. 3, 25–27 (2015).

The work was performed in accordance with the application for the grant of the Russian National Fund No. 19-19-00142.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 55, No. 3, pp. 24–27, March, 2019.

Rights and permissions

About this article

Cite this article

Shcherba, V.Е., Shalai, V.V., Kuzhbanov, A.K. et al. Utilization of Compressed Gas Heat for Fluid Compression and Movement in a Displacement Pump. Chem Petrol Eng 55, 216–222 (2019). https://doi.org/10.1007/s10556-019-00608-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-019-00608-7