Abstract

Polyvinylidene fluoride (PVDF) microstructures are of interest for a number of BioMEMS applications both for their piezoelectric and biocompatible properties. In this work, simple soft lithography-based techniques were developed to fabricate PVDF microstructures with diverse geometries, including microarrays of pillars, lines, and wells. Four different microstructure configurations were created: freestanding, stamped discontinuous, stamped continuous and imprinted patterns. Features with lateral dimensions down to 1 μm were consistently reproduced on 2.5 cm diameter areas. Atomic force microscopy (AFM) measurements of poled PVDF microstructures confirmed a marked inverse piezoelectric behavior. The techniques presented here have a number of advantages over previously demonstrated PVDF micropatterning approaches.

Similar content being viewed by others

References

R. Bashir, Adv Drug Deliv Rev 56, 1565–1586 (2004)

E. Bormashenko, R. Pogreb, Y. Socol, M.H. Itzhaq, V. Streltsov, S. Sutovski, A. Sheshnev, Y. Bormashenko, Opt Mater 27, 429–434 (2004)

Q.X. Chen, P.A. Payne, Meas Sci Technol 6, 249–267 (1995)

W.J. Choi, Y. Jeon, J.H. Jeong, R. Sood, S.G. Kim, J Electroceram 17, 543–548 (2006)

Y.H. Chu, L.W. Martin, M.B. Holcomb, M. Gajek, S.J. Han, Q. He, N. Balke, C.H. Yang, D. Lee, W. Hu, Q. Zhan, P.L. Yang, A. Fraile-Rodriguez, A. Scholl, S.X. Wang, R. Ramesh, Nat Mater 7, 478–482 (2008)

G.V. Cochran, M.W. Johnson, M.P. Kadaba, F. Vosburgh, M.W. Ferguson-Pell, V.R. Palmieri, J Orthop Res 3, 508–513 (1985)

A. Dubach, R. Raghavan, J. Löffler, J.J. Michler, U. Ramamurty, Scr Mater 60, 567–570 (2009)

N. Ferrell, J. Woodard, D. Hansford, Biomed Microdevices 9, 815–821 (2007)

M.T. Frey, I.Y. Tsai, T.P. Russell, S.K. Hanks, Y.L. Wang, Biophys J 90, 3774–3782 (2006)

D. Gallego, N. Ferrell, Y. Sun, D.J. Hansford, Mater Sci Eng C Biomim Mater Sens Syst 28, 353–358 (2008)

M. Ghibaudo, L. Trichet, J.L. Digabel, A. Richert, P. Hersen, B. Ladoux, Biophys J 97, 357–368 (2009)

M. Goel, Curr Sci 85, 443–453 (2003)

M.L.K. Hoa, M. Lu, Y. Zhang, Adv Colloid Interface Sci 121, 9–23 (2006)

Z.J. Hu, G. Baralia, V. Bayot, J.F. Gohy, A.M. Jonas, Nano Lett 5, 1738–1743 (2005)

Z.J. Hu, M.W. Tian, B. Nysten, A.M. Jonas, Nat Mater 8, 62–67 (2009)

C.H. Hung, Y.L. Lin, T.H. Young, Biomaterials 27, 4461–4469 (2006)

J. Iqbal, M. Zaidi, Biochem Biophys Res Commun 328, 751–755 (2005)

D. Ivanov, BioDrugs 20, 351–356 (2006)

K. Junwu, Y. Zhigang, P. Taijiang, C. Guangming, W. Boda, Sens Actuators A Phys 12, 156–161 (2005)

S.J. Kang, Y.J. Park, J. Hwang, H.J. Jeong, J.S. Lee, K.J. Kim, H.C. Kim, J. Huh, C. Park, Adv Mater 19, 581–586 (2007)

H. Kawai, Jpn J Appl Phys 8, 975–976 (1969)

A. Khademhosseini, R. Langer, J. Borestein, J.P. Vacanti, Proc Natl Acad Sci USA 103, 2480–2487 (2006)

D. Klee, Z. Ademovic, A. Bosserhoff, H. Hoecker, G. Maziolis, H.-J. Erli, Biomaterials 24, 3663–3670 (2003)

U. Klinge, B. Klosterhalfen, A.P. Ottinger, K. Junge, V. Schumpelick, Biomaterials 23, 3487–3493 (2002)

J.B. Lando, W.W. Doll, J Macromol Sci Phys B 2, 205–218 (1968)

S.B. Lang, S. Muensit, Appl Phys A 85, 125–134 (2006)

S. Lee, E.V. Bordatchev, M.J.F. Zeman, J Micromech Microeng 18, 045011 (2008)

D. Li, D.A. Bonnell, Annu Rev Mater Res 38, 351–368 (2008)

J.Y. Li, R.C. Rogan, E. Ustundag, K. Bhattacharya, Nat Mater 4, 776–781 (2005)

Y. Liu, D.N. Weiss, J. Li, ACS Nano 4, 83–90 (2010)

O. Loh, A. Vaziri, H.D. Espinosa, Exp Mech 49, 105–124 (2009)

N.B. Narayanan, A. Bonakdar, J. Dargahi, M. Packirisamy, R. Bhat, Smart Mater Struct 15, 1684–1690 (2006)

A. Navarro, S.A. Rocks, R.A. Dorey, J Electroceram 19, 321–326 (2007)

H. Ohigashi, J Appl Phys 47, 949–955 (1976)

S. Ozeri, D. Shmilovitz, J. Fainguelernt, Ind Electron 2006 IEEE Int Symp 4, 2840–2845 (2006)

Y.J. Park, Y.S. Kang, C. Park, Eur Polym J 41(5), 1002–1012 (2005)

J.F. Scott, M. Dawber, A.Q. Jiang, F.D. Morrison, Ferroelectrics 286, 945–957 (2003)

D.B. Serrell, J. Law, A.J. Slifka, L. Mahajan, D.S. Finch, Biomed Microdevices 10, 883–889 (2008)

K.G. Sharp, G.S. Blackman, N.J. Glassmaker, A. Jagota, C. Hui, Langmuir 20, 6430–6438 (2004)

Y. Shen, U.C. Wejinya, N. Xi, C.A. Pomeroy, Proc IMechE 221, 99–112 (2007)

J.W. Sohn, S.B. Choi, D.Y. Lee, Proc IMechE 219, 429–436 (2005)

S.M. Spearing, Acta Mater 48, 179–196 (2000)

K. Tashiro, H. Tadokoro, M. Kobayashi, Ferroelectrics 32, 167–175 (1981)

E. Urban, M.W. King, R. Guidoin, G. Laroche, Y. Marois, L. Martin, A. Cardou, Y. Douville, ASAIO J 40, 145–156 (1994)

A. Wada, H. Kubota, H. Hatanaka, H. Miura, Y. Iwamoto, J Hand Surg [Br] 26, 212–216 (2001)

F. Wang, M. Tanaka, S. Chonan, J Intell Mater Syst Struct 14, 185–190 (2003)

Y. Xia, G.M. Whitesides, Annu Rev Mater Sci 28, 153–184 (1998)

B. Xu, F. Arias, G.M. Whitesides, Adv Mater 11, 492–495 (1999a)

B. Xu, F. Arias, S.T. Brittain, X.M. Zhao, B. Grzybowski, S. Torquato, G.M. Whitesides, Adv Mater 11, 1186–1189 (1999b)

J. Xu, M.J. Dapino, D. Gallego-Perez, D. Hansford, Sens Actuators A Phys 153, 24–32 (2009)

H. Zhang, D.W. Hutmacher, F. Chollet, A.N. Poo, E. Burdet, Macromol Biosci 5, 477–489 (2005)

L. Zhang, S. Ducharme, J. Li, Appl Phys Lett 91, 172906 (2007)

W. Zhou, Y. Huang, E. Menard, N.R. Aluru, J.A. Rogers, A.G. Alleyne, Appl Phys Lett 87, 251925 (2005)

Acknowledgments

The authors would like to thank Edward Meier, Jian Xu and Dr. Marcelo Dapino (The Ohio State University) for helpful discussion, and the Nanotech West Laboratory staff for technical assistance. This work was funded by AFOSR MURI contract # F49620-03-1-0421.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

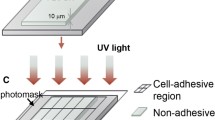

Supplementary Figure 1

(a) Setup used for patterning/transferring PVDF microstructures using heat and pressure, (b) Close-up showing a patterned PVDF film being transferred from the PDMS mold onto a conductive substrate. (DOCX 1755 kb)

Supplementary Figure 2

(a) PDMS stamp being peeled away from the patterned PVDF film, (b) PVA layer being lifted out of the PDMS mold (carrying the PVDF microstructures), (c) PVDF microstructures stamped on a rigid substrate (left), flexible substrate (middle), and on the PVA layer (right). Inset shows a SEM micrograph of a freestanding PVDF microstructure recovered by filtering the dissolved PVA layer. (DOCX 2135 kb)

Supplementary Figure 3

(a) Poling and (b) actuation setups (inset in (a) shows a close-up of the sample with the connections made to the power supply). (DOCX 2056 kb)

Rights and permissions

About this article

Cite this article

Gallego-Perez, D., Ferrell, N.J., Higuita-Castro, N. et al. Versatile methods for the fabrication of polyvinylidene fluoride microstructures. Biomed Microdevices 12, 1009–1017 (2010). https://doi.org/10.1007/s10544-010-9455-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10544-010-9455-9