Abstract

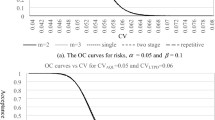

Various acceptance sampling plans have been developed for different objectives. A repetitive group sampling (RGS) plan has been shown to be an efficient and easy-to-implement scheme for lot sentencing. However, it does not consider the available information from preceding samples. As a result, it may reduce the sampling efficiency in terms of cost and time. In this study, a modified variables RGS plan is proposed based on the commonly used capability index \(C_{pk}\) for normally distributed processes with two-sided specification limits and to consider the sample results from preceding lots. The plan parameters for various required quality levels and allowable risks are tabulated for practical applications, and the advantages of the proposed plan is compared with existing variables sampling plans in terms of operating characteristic curve and average sample size.

Similar content being viewed by others

References

Aslam, M., Azam, M., & Jun, C. H. (2013a). Multiple dependent state sampling plan based on process capability index. Journal of Testing and Evaluation, 41(2), 340–346.

Aslam, M., Wu, C. W., Azam, M., & Jun, C. H. (2013b). Variable sampling inspection for resubmitted lots based on process capability index \(C_{pk}\) for normally distributed items. Applied Mathematical Modelling, 37, 667–675.

Aslam, M., Wu, C. W., Azam, M., & Jun, C. H. (2014). Mixed acceptance sampling plans for product inspection using process capability index. Quality Engineering, 26, 450–459.

Balamurali, S., & Jun, C. H. (2006). Repetitive group sampling procedure for variables inspection. Journal of Applied Statistics, 33(3), 327–338.

Balamurali, S., & Jun, C. H. (2007). Multiple dependent state sampling plans for lot acceptance based on the measurement data. European Journal of Operational Research, 180, 1221–1230.

Balamurali, S., & Jun, C. H. (2009). Designing of a variables two-plan system by minimizing the average sample number. Journal of Applied Statistics, 36(10), 1159–1172.

Balamurali, S., Park, H., Jun, C. H., Kim, K. J., & Lee, J. (2005). Designing of variables repetitive group sampling plan involving minimum average sample number. Communication in Statistics-Simulation and Computation, 34(3), 799–809.

Boyles, R. A. (1991). The Taguchi capability index. Journal of Quality Technology, 23, 107–126.

Franklin, L. A., & Wasserman, G. S. (1992). Bootstrap lower confidence limits for capability indices. Journal of Quality Technology, 24(4), 196–210.

Hoffman, L. L. (2001). Obtaining confidence intervals for \(C_{pk}\) using percentiles of the distribution of \(C_{p}\). Quality and Reliability Engineering International, 17(2), 113–118.

Kane, V. E. (1986). Process capability indices. Journal of Quality Technology, 18, 41–52.

Kotz, S., & Johnson, N. L. (1993). Process capability indices. London, UK: Chapman & Hall.

Kotz, S., & Johnson, N. L. (2002). Process capability indices—a review, 1992–2000. Journal of Quality Technology, 34(1), 1–19.

Kotz, S., & Lovelace, C. (1998). Process capability indices in theory and practice. London, UK: Arnold.

Kushler, R., & Hurley, P. (1992). Confidence bounds for capability indices. Journal of Quality Technology, 24, 188–195.

Liu, S. H., Lin, S. W., & Wu, C. W. (2014). A resubmitted sampling scheme by variables inspection for controlling lot fraction nonconforming. International Journal of Production Research, 52(12), 3744–3754.

Mathew, T., Sebastian, G., & Kurian, K. M. (2007). Generalized confidence intervals for process capability indices. Quality and Reliability Engineering International, 23(4), 471–481.

Montgomery, D. C. (2009). Introduction to Statistical Quality Control (6th ed.). New York: Wiley.

Nagata, Y., & Nagahata, H. (1994). Approximation formulas for the lower confidence limits of process capability indices. Okayama Economic Review, 25, 301–314.

Negrin, I., Parmet, Y., & Schechtman, E. (2009). Developing a sampling plan based on \(C_{pk}\). Quality Engineering, 21, 306–318.

Negrin, I., Parmet, Y., & Schechtman, E. (2011). Developing a sampling plan based on \(C_{pk }\)—unknown variance. Quality and Reliability Engineering International, 27(1), 3–14.

Palmera, K., & Tsui, K. L. (1999). A review and interpretations of process capability indices. Annals of Operations Research, 87, 31–47.

Pearn, W. L., & Lin, P. C. (2004). Testing process performance based on capability index \(C_{pk}\) with critical value. Computers and Industrial Engineering, 47, 351–369.

Pearn, W. L., & Wu, C. W. (2006). Critical acceptance values and sample sizes of a variables sampling plan for very low fraction of defective. Omega, 34, 90–101.

Pearn, W. L., & Wu, C. W. (2007). An effective decision making method for product acceptance. Omega, 35, 12–21.

Sherman, R. E. (1965). Design and evaluation of repetitive group sampling plan. Technometrics, 7(1), 11–21.

Tang, L. C., Than, S. E., & Ang, B. W. (1997). A graphical approach to obtaining confidence limits of \(C_{pk}\). Quality and Reliability Engineering International, 13, 337–346.

Vännman, K. (1997). Distribution and moments in simplified form for a general class of capability indices. Communications in Statistics: Theory and Methods, 26, 159–179.

Wortham, A. W., & Baker, R. C. (1976). Multiple deferred state sampling inspection. International Journal of Production Research, 14(6), 719–731.

Wu, C. W. (2012). An efficient inspection scheme for variables based on Taguchi capability index. European Journal of Operational Research, 223(1), 116–122.

Wu, C. W., Aslam, M., Chen, J. C., & Jun, C. H. (2015a). A repetitive group sampling plan by variables inspection for product acceptance determination. European Journal of Industrial Engineering, 9(3), 308–326.

Wu, C. W., Aslam, M., & Jun, C. H. (2012). Variables sampling inspection scheme for resubmitted lots based on the process capability index \(C_{pk}\). European Journal of Operational Research, 217, 560–566.

Wu, C. W., Lee, A. H. I., & Chen, Y. W. (2015b). A novel lot sentencing method by variables inspection considering multiple dependent state. Quality and Reliability Engineering International. doi:10.1002/qre.1808.

Wu, C. W., & Liu, S. W. (2014). Developing a sampling plan by variables inspection for controlling lot fraction of defectives. Applied Mathematical Modelling, 38(9–10), 2303–2310.

Wu, C. W., & Pearn, W. L. (2008). A variable sampling plan based on \(C_{pmk}\) for product acceptance determination. European Journal of Operational Research, 184, 549–560.

Wu, C. W., Pearn, W. L., & Kotz, S. (2009b). An overview of theory and practice on process capability indices for quality assurance. International Journal of Production Economics, 117(2), 338–359.

Wu, C. W., Shu, M. H., & Cheng, F. T. (2009a). Generalized confidence intervals for assessing process capability of multiple production lines. Quality and Reliability Engineering International, 25(6), 701–716.

Wu, C. W., Shu, M. H., Pearn, W. L., & Liu, K. H. (2008). Bootstrap approach for supplier selection based on production yield. International Journal of Production Research, 46(18), 5211–5230.

Yum, B. J., & Kim, K. W. (2011). A bibliography of the literature on process capability indices: 2000–2009. Quality and Reliability Engineering International, 27(3), 251–268.

Acknowledgments

This work was partially supported by the Ministry of Science and Technology, Taiwan under Grant No. MOST 103-2221-E-007-103-MY3 and the Ministry of Education, Taiwan under Grant No. 103N2075E1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, A.H.I., Wu, CW. & Chen, YW. A modified variables repetitive group sampling plan with the consideration of preceding lots information. Ann Oper Res 238, 355–373 (2016). https://doi.org/10.1007/s10479-015-2064-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-015-2064-5