Abstract

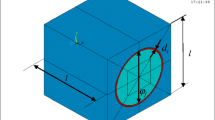

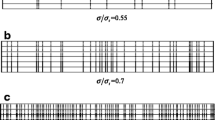

Multi-scale models play an important role in capturing the nonlinear response of woven carbon fiber reinforced ceramic matrix composites. In plain weave carbon fiber/silicon carbon (C/SiC) composites, the carbon fibers and interphases will be oxidized at elevated temperature and the strength of the composite will be degraded when oxygen enters micro-cracks formed in the as-produced parts due to the mismatch in thermal properties between constituents. As a result of the oxidation on fiber surface, fiber shows a notch-like morphology. In this paper, the change rule of fiber notch depth is fitted by circular function. And a multi-scale model based upon the change rule of fiber notch depth is developed to simulate the residual strength and post-oxidation stress–strain curves of the composite. The multi-scale model is able to accurately predict the residual strength and post-oxidation stress–strain curves of the composite. Besides, the simulated residual strength and post-oxidation stress–strain curves of 2D plain weave C/SiC composites in oxidation atmosphere show good agreements with experimental results. Furthermore, the oxidation time and temperature of the composite are investigated to show their influences upon the residual strength and post-oxidation stress–strain curves of plain weave C/SiC composites.

Similar content being viewed by others

References

Aboudi, J.: The effect of anisotropic damage evolution on the behavior of ductile and brittle matrix composites. Int. J. Solids Struct. 48, 2102–19 (2011)

Camus, G., Guillaumat, L., Baste, S.: Development of damage in a 2D woven C/SiC composite under mechanical loading: I. Mechanical characterization. Compos. Sci. Technol. 56, 1363–72 (1996)

El Bouazzaoui, R., Baste, S., Camus, G.: Development of damage in a 2D woven C/SiC composite under mechanical loading: II. Ultrasonic characterization. Compos. Sci. Technol. 56, 1373–82 (1996)

Gowayed, Y., Abouzeida, E., Smyth, I., Ojard, G., Ahmad, J., Santhosh, U., et al.: The role of oxidation in time-dependent response of ceramic–matrix composites. Compos. Part B 76, 20–30 (2015)

Dalmaz, A., Ducret, D., El Guerjouma, R., Reynaud, P., Franciosi, P., Rouby, D., et al.: Elastic moduli of a 2.5D Cf/SiC composite: experimental and theoretical estimates. Compos. Sci. Technol. 60, 913–25 (2000)

Gou, J., Dai, Y., Li, S., Tao, W.: Numerical study of effective thermal conductivities of plain woven composites by unit cells of different sizes. Int. J. Heat Mass Transf. 91, 829–40 (2015)

Naslain, R.: Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Compos. Sci. Technol. 64, 155–70 (2004)

Kumar, S., Kumar, A., Sampath, K., Bhanu Prasad, V.V., Chaudhary, J.C., Gupta, A.K., et al.: Fabrication and erosion studies of C–SiC composite Jet Vanes in solid rocket motor exhaust. J. Eur. Ceram. Soc. 31, 2425–31 (2011)

Naslain, R., Guette, A., Rebillat, F., Le Gallet, S., Lamouroux, F., Filipuzzi, L., et al.: Oxidation mechanisms and kinetics of SiC-matrix composites and their constituents. J. Mater. Sci. 39, 7303–16 (2004)

Xu, Y., Zhang, P., Lu, H., Zhang, W.: Numerical modeling of oxidized C/SiC microcomposite in air oxidizing environments below 800 °C: microstructure and mechanical behavior. J. Eur. Ceram. Soc. 35, 3401–9 (2015)

Borkowski, L., Chattopadhyay, A.: Multiscale model of woven ceramic matrix composites considering manufacturing induced damage. Compos. Struct. 126, 62–71 (2015)

Lu, Z., Zhou, Y., Yang, Z., Liu, Q.: Multi-scale finite element analysis of 2.5D woven fabric composites under on-axis and off-axis tension. Comput. Mater. Sci. 79, 485–94 (2013)

Sun, Z., Wang, Z., Song, Y.: Verification and prediction of elastic modulus of C/SiC composites under non-stress oxidation. Acta Mat. Compos. Sin. 30, 172–80 (2013)

Niu, X., Sun, Z., Kong, C.: Elastic modulus prediction of three-dimension-4 directional braided Cf/SiC composite based on double-scale model. J. Wuhan Univ. Technol. 30, 500–8 (2015)

Gao, X., Song, Y., Sun, Z.: Numerical simulation of dynamic response of fiber reinforced ceramic matrix composite beam with matrix cracks using multiscale modeling. Chin. J. Aeronaut. 23, 537–48 (2010)

Cui, Y., Li, A., Li, B., Ma, X., Bai, R., Zhang, W., et al.: Microstructure and ablation mechanism of C/C–SiC composites. J. Eur. Ceram. Soc. 34, 171–7 (2014)

Sun, Z., Niu, X., Wang, Z., Song, Y., Wang, X.: Verification and prediction of residual strength of C/SiC composites under non-stress oxidation. J. Mater. Sci. 49, 8192–203 (2014)

Yang, C.P., Jiao, G.Q., Wang, B., Huang, T.: Mechanical degradation mechanisms of 2D-C/SiC composites: influences of preloading and oxidation. J. Eur. Ceram. Soc. 35, 2765–73 (2015)

Naslain, R., Lamon, J., Pailler, R., Bourrat, X., Guette, A., Langlais, F.: Micro/minicomposites: a useful approach to the design and development of non-oxide CMCs. Compos. A: Appl. Sci. Manuf. 30, 537–47 (1999)

Steyer, T.E., Zok, F.W., Walls, D.P.: Stress rupture of an enhanced nicalon/silicon carbide composite at intermediate temperatures. J. Am. Ceram. Soc. 81, 2140–6 (1998)

Xi, C., Zhang, L., Hui, M., Cheng, L., Deng, X., Zhenye, X.U.: Testing and evaluation of oxidation damages in 2D C/SiC by thermography. Fuhe Cailiao Xuebao/Acta Mat. Compos. Sin. 28, 112–8 (2011)

Sun, Z., Shao, H., Niu, X., Song, Y.: Simulation of mechanical behaviors of ceramic composites under stress-oxidation environment while considering the effect of matrix cracks. Appl. Compos. Mater. 1–18 (2016)

Sun, Z., Shao, H., Niu, X., Song, Y.: Failure simulation of unidirectional fiber-reinforced ceramic matrix composites based on evolving compliant interfacial debonding model. Mater. Sci. Eng. A (2016)

Jones, R.H., Henager Jr., C.H.: Subcritical crack growth processes in SiC/SiC ceramic matrix composites. J. Eur. Ceram. Soc. 25, 1717–22 (2005)

Kerans, R.J., Rebillat, F., Lamon, J.: Fiber—matrix interface properties of single-fiber microcomposites as measured by fiber pushin tests. J. Am. Ceram. Soc. 80, 506–8 (1997)

Zhang, J., Luan, X., Cheng, L., Zhang, L.: Damage evolution in 3D C_f/SiC composites in stressed oxidation environments. Kuei Suan Jen Hsueh Pao/J. Chin. Ceram. Soc. 38, 799–804 (2010)

Sun, Z.G., Yan, M., Song, Y.D.: Simulating and validating the stress–strain curve of the matrix cracking of ceramic matrix composite. Hangkong Dongli Xuebao/J. Aerosp. Power 27, 2056–62 (2012)

Si-Da, L.U., Gao, X.G., Song, Y.D.: Prediction method on equivalent thermal conductivity coefficient of plain braided C/SiC composites material based on finite element method. Hangkong Dongli Xuebao/J. Aerosp. Power 29, 1574–82 (2014)

Xia, Z., Zhang, Y., Ellyin, F.: A unified periodical boundary conditions for representative volume elements of composites and applications. Int. J. Solids Struct. 40, 1907–21 (2003)

Curtin, W.A.: Theory of mechanical properties of ceramic-matrix composites. J. Am. Ceram. Soc. 74, 2837–45 (1991)

Yang, C.P., Jiao, G.Q., Wang, B.: Calculation model for residual strength of C/SiC composites after oxidation. J. Mech. Strength 33, 106–10 (2011)

Yang, C., Jiao, G., Bo, W., Long, D.U.: Oxidation damages and a stiffness model for 2D-C/SiC composites. Fuhe Cailiao Xuebao/Acta Mat. Compos. Sin. 26, 175–81 (2009)

Acknowledgments

Supports of this project provided by National Basic Research Program of China, National Natural Science Foundation of China (51575261), Aeronautical Science Foundation of China (2012ZB52026,2014ZB52024), the Fundamental Research Funds for the Central Universities (NJ20160038) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, X., Sun, Z., Sun, J. et al. Multi-scale Model of Residual Strength of 2D Plain Weave C/SiC Composites in Oxidation Atmosphere. Appl Compos Mater 24, 1–22 (2017). https://doi.org/10.1007/s10443-016-9511-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-016-9511-6