Abstract

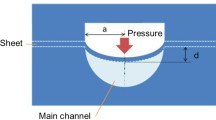

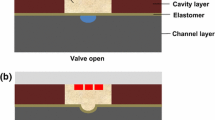

While much research has been conducted on elastomeric valves within PDMS microfluidic devices, we rarely see scalable manufacturing processes for integrating such valves into rigid thermoplastic devices. Most thermoplastic materials do not share intrinsic bonding compatibility to flexible elastomer membranes, making it difficult to ensure leak-proof operation of such valves within thermoplastic devices. In order to overcome bonding compatibility issues, we propose decoupling the valve architecture from the fluidic routing device layers. This can be achieved by prefabricating modular valves via molding processes and subsequently inserting them into thermoplastic layers containing valve seats. Thermoplastic layers containing modular valves are then thermally bonded to thermoplastic layers containing the fluidic routing channels, resulting in leak-proof valve integration. At valve actuation pressures of approximately 60 kPa, the modular membrane valves seal fluidic channels operating at a flow rate of 100 µl min−1. Modular valves that were incorporated into a concentration gradient generator demonstrated dynamically configurable fluid routing at a response frequency of 5 Hz. The integration of modular membrane valves is an effective solution to streamline and cost-down the manufacturing of hybrid elastomer–thermoplastic devices. As this solution does not rely on bonding compatibility between the elastomeric membranes and the thermoplastic device, it can be applied universally to solve integration issues for low-cost thermoplastic device fabrication.

Similar content being viewed by others

References

Araci IE, Quake SR (2012) Microfluidic very large scale integration (mVLSI) with integrated micromechanical valves. Lab Chip 12(16):2803–2806

Chen C-F, Liu J, Chang C-C, DeVoe DL (2009) High-pressure on-chip mechanical valves for thermoplastic microfluidic devices. Lab Chip 9(24):3511–3516

Elizabeth Hulme S, Shevkoplyas SS, Whitesides GM (2009) Incorporation of prefabricated screw, pneumatic, and solenoid valves into microfluidic devices. Lab Chip 9(1):79–86

Fan ZH, Gu P, Augustine S, Liu K, Freitag H, Nishida T (2012) Microfluidic valve arrays in thermoplastic devices. In: ASME 2012 10th international conference on nanochannels, microchannels, and minichannels. Rio Grande, Puerto Rico, USA, ASME. ICNMM2012-73021, pp 453–458

Gu P, Liu K, Chen H, Nishida T, Fan ZH (2010) Chemical-assisted bonding of thermoplastics/elastomer for fabricating microfluidic valves. Anal Chem 83(1):446–452

Hansen C, Quake SR (2003) Microfluidics in structural biology: smaller, faster… better. Curr Opin Struct Biol 13(5):538–544

Jeon NL, Dertinger SKW, Chiu DT, Choi IS, Stroock AD, Whitesides GM (2000) Generation of solution and surface gradients using microfluidic systems. Langmuir 16(22):8311–8316

Kuo JS, Chiu DT (2011) Disposable microfluidic substrates: Transitioning from the research laboratory into the clinic. Lab Chip 11(16):2656–2665

Lee KS, Ram RJ (2009) Plastic-PDMS bonding for high pressure hydrolytically stable active microfluidics. Lab Chip 9(11):1618–1624

Lee M, Lopez-Martinez MJ, Baraket A, Zine N, Esteve J, Plaza JA, Jaffrezic-Renault N, Errachid A (2013) Polymer micromixers bonded to thermoplastic films combining soft-lithography with plasma and aptes treatment processes. J Polym Sci Part A Polym Chem 51(1):59–70

Nguyen NT, Wereley S (2002) Fundamentals and applications of microfluidics. Artech House, Boston

Ogilvie IRG, Sieben VJ, Cortese B, Mowlem MC, Morgan H (2011) Chemically resistant microfluidic valves from Viton® membranes bonded to COC and PMMA. Lab Chip 11(14):2455–2459

Qin D, Xia Y, Whitesides GM (2010) Soft lithography for micro- and nanoscale patterning. Nat Protocols 5(3):491–502

Sackmann EK, Fulton AL, Beebe DJ (2014) The present and future role of microfluidics in biomedical research. Nat Rev 507:181–189

Scott A, Au AK, Vinckenbosch E, Folch A (2013) A microfluidic D-subminiature connector. Lab Chip 13(11):2036–2039

Shaegh S, Wang Z, Ng S, Wu R, Nguyen H, Chan L, Toh A, Wang Z (2015) Plug-and-play microvalve and micropump for rapid integration with microfluidic chips. Microfluid Nanofluid 19(3):557–564

Shanshi H, Qiaohong H, Xianqiao H, Hengwu C (2012) Fabrication of micro pneumatic valves with double-layer elastic poly(dimethylsiloxane) membranes in rigid poly(methyl methacrylate) microfluidic chips. J Micromech Microeng 22(8):085008

Sunkara V, Park D-K, Cho Y-K (2012) Versatile method for bonding hard and soft materials. RSC Adv 2(24):9066–9070

Sunkara V, Park D-K, Hwang H, Chantiwas R, Soper SA, Cho Y-K (2011) Simple room temperature bonding of thermoplastics and poly(dimethylsiloxane). Lab Chip 11(5):962–965

Tang L, Lee NY (2010) A facile route for irreversible bonding of plastic-PDMS hybrid microdevices at room temperature. Lab Chip 10(10):1274–1280

Timoshenko SP, Woinowsky-Krieger S (1959) Theory of plates and shells. McGraw-hill, New York

Toh AGG, Ng SH, Wang Z (2009) Fabrication and testing of embedded microvalves within PMMA microfluidic devices. Microsyst Technol 15(9):1335–1342

Tsao C-W, DeVoe D (2009) Bonding of thermoplastic polymer microfluidics. Microfluid Nanofluid 6(1):1–16

Unger MA, Chou H-P, Thorsen T, Scherer A, Quake SR (2000) Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 288(5463):113–116

Wheeler AR, Throndset WR, Whelan RJ, Leach AM, Zare RN, Liao YH, Farrell K, Manger ID, Daridon A (2003) Microfluidic device for single-cell analysis. Anal Chem 75(14):3581–3586

Wu J, Lee NY (2014) One-step surface modification for irreversible bonding of various plastics with a poly(dimethylsiloxane) elastomer at room temperature. Lab Chip 14:1564–1571

Acknowledgments

This work was supported by the Agency for Science, Technology and Research (A*STAR). Device fabrication was supported by the SIMTech Microfluidics Foundry.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 2 (WMV 466 kb)

Supplementary material 3 (WMV 857 kb)

Rights and permissions

About this article

Cite this article

Toh, A.G.G., Wang, Z. & Wang, Z. Modular membrane valves for universal integration within thermoplastic devices. Microfluid Nanofluid 20, 85 (2016). https://doi.org/10.1007/s10404-016-1753-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-016-1753-y