Abstract

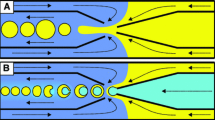

Droplets formed under the buoyancy force in a quiescent continuous phase provides a facile yet interesting system for fundamental studies on the drop-rupture mechanism, which was a field of vast research interest prior to the arrival of the microfluidic techniques. The formation of macro-drops via a microchannel in a buoyancy-driven system is revisited for three low-viscosity hydrocarbon oils using a wide range of surfactant concentrations. The dripping-to-jetting transition was found to occur at a Bond number of ~0.85, reflecting the significance of buoyancy force even in the jetting regime. The pinch-off time and the satellite drops were found to have negligible impact on the final drop volume throughout the dripping regime. A modified force balance model is presented which includes the dynamic interfacial tension based on the surface-average age of the drop. The model clearly predicts a region where the drop size increases initially with dispersed phase flow rate (Q) due to increasing dynamic interfacial tension, followed by a region of constant drop size with Q, where the increase in interfacial force is compensated by an equal increase in the kinetic force. Polydispersity in the drops formed under the jetting regime was found to vary in accordance with the polydispersity in the break-up length of the drops. Interestingly, highly monodisperse drops were not limited to dripping regime and formed under the jetting regime at a higher frequency too, but only under certain flow rate and interfacial tension conditions.

Similar content being viewed by others

References

Addison CC, Elliott TA (1950) The properties of freshly formed surfaces. Part Xv. The application of the contracting liquid-jet technique to the measurement of tensions at liquid–liquid interfaces. J Chem Soc 3090

Awwad AM, Al-Azzawi SF, Salman MA (1986) Volumes and viscosities of benzene+ n-alkane mixtures. Fluid Phase Equilib 31(2):171–182

Barhate RS, Patil G, Srinivas ND, Raghavarao KSMS (2004) Drop formation in aqueous two-phase systems. J Chromatogr A 1023:197–206

Bohr N (1909) Determination of the surface-tension of water by the method of jet vibration. Philos Trans R Soc Lond Ser A 209:281

Bremond N, Carreras ES, Chu LY, Bibette J (2010) Formation of liquid-core capsules having a thin hydrogel membrane: liquid pearls. Soft Matter 6:2484–2488

Chang TMS (2004) Artificial cell bioencapsulation in macro, micro, nano and molecular dimensions: keynote lecture. Artif Cell Blood Substitut Biotechnol 32(1):1–23

Chen Y, Wu L, Zhang C (2013) Emulsion droplet formation in coflowing streams. Phys Rev E 87:013002

Chevalier JLE, Petrino PJ, Gaston-Bonhomme YH (1990) Viscosity and density of some aliphatic, cyclic, and aromatic hydrocarbons binary liquid mixtures. J Chem Eng Data 35(2):206–212

Clanet C, Lasheras J (1999) Transition from dripping to jetting. J Fluid Mech 383:307–326

Cordero ML, Fallaire F, Baroud CN (2011) Quantitative analysis of the dripping and jetting regimes in co-flowing capillary jets. Phys Fluids 23(9):094111

Cramer C (2004) Continuous drop formation at a capillary tip and drop deformation in a flow channel. Laboratory of Food Process Engineering, Swiss Federal Institute of Technology (ETH) Zürich ISBN:3-905609-22-3. http://e-collection.library.ethz.ch/view/eth:27332

Cramer C, Fischer P, Windhab EJ (2004) Drop formation in a co-flowing ambient fluid. Chem Eng Sci 59:3045–3058

Cramer C, Studer S, Windhab EJ, Fischer P (2012) Periodic dripping dynamics in a co-flowing liquid–liquid system. Phys Fluids 24:093101

de Chazal L, Ryan J (1971) Formation of organic drops in water. A1ChE J 17:1226–1229

del Rio OI, Neumann AW (1997) Axisymmetric drop shape analysis: computational methods for the measurement of interfacial properties from the shape and dimensions of pendant and sessile drops. J Colloid Interface Sci 196:136–147

Edwards DA, Hanes J, Caponetti G, Hrkach J, Ben-Jebria A, Eskew ML, Mintzes J, Deaver D, Lotan N, Langer R (1997) Large porous particles for pulmonary drug delivery. Science 276:1868–1871

Erb RM, Obrist D, Chen PW, Studer J, Studart AR (2011) Predicting sizes of droplets made by microfluidic flow-induced dripping. Soft Matter 7:8757

Euliss LE, DuPont JA, Gratton S, DeSimone J (2006) Imparting size, shape, and composition control of materials for nanomedicine. Chem Soc Rev 35:1095–1104

Garner FH, Mina P (1959) Surface ageing at liquid–liquidinterfaces. Trans Faraday Soc 55:1607–1626

Harkins WD, Brown FE (1919) The determination of surface tension (free surface energy), and the weight of falling drops—the surface tension of water and benzene by the capillary height method. J Am Chem Soc 41:499

Hayworth CB, Treybal RE (1950) drop formation in two-liquid-phase systems. Ind Eng Chem 42:1174

Heertjes P, de Nie L, de Vries H (1971) Drop formation in liquid–liquid systems—prediction of drop volumes at moderate speed of formation. Chem Eng Sci 26:441–449

Joscelyne SM, Taragardh G (2000) Membrane emulsification—a literature review. J Membr Sci 169:107–117

Josephides DN, Sajjadi S (2014) Microfluidic method for creating monodisperse viscous single emulsions via core–shell templating. Microfluid Nanofluid. doi:10.1007/s10404-014-1439-2

Mitragotri S, Lahann J (2009) Physical approaches to biomaterial design. Nat Mater 8:15–23

Nie Z, Seo MS, Xu S, Lewis PC, Mok M, Kumacheva E, Whitesides GM, Garstecki P, Stone HA (2008) Emulsification in a microfluidic flow-focusing device: effect of the viscosities of the liquids. Microfluid Nanofluid 5:585–594

Rao EVLN, Kumar R, Kuloor NR (1966) Drop formation studies in liquid–liquid systems. Chem Eng Sci 21:867–880

Ravi Kumar MN (2000) Nano and microparticles as controlled drug delivery devices. J Pharm Pharm Sci 3:234–258

Richards JR, Lenhoff AM, Beris AN (1994) Dynamic breakup of liquid–liquid jets. Phys Fluids 6:2640

Saad SMI, Policova Z, Neumann AW (2011) Design and accuracy of pendant drop methods for surface tension measurement. Colloids Surf A Physicochem Eng Asp 384:442–452

Sauret A, Shum HC (2012) Beating the jetting regime. Int J Nonlinear Sci Numer Simul 13(5):351

Scheele GF, Meister BJ (1968) Drop formation at low velocities in liquid–liquid systems: part I. Prediction of drop volume. AIChE J. 14:9–15

Schoeler AM, Josephides DN, Chaurasia AS, Sajjadi S, Mesquida P (2014) Electrophoretic manipulation of multiple-emulsion droplets. Appl Phys Lett 104:074104

Shah RK, Shum HC, Rowat AC, Lee D, Agresti JJ, Utada AS, Chu LY, Kim JY, Nieves AF, Martinez CJ, Weitz DA (2008) Designer emulsions using microfluidics. Mater Today 11(4):18–27

Tate T (1864) On the magnitude of a drop of liquid formed under different circumstances. Philos Mag 27:176

Utada AS, Lorenceau E, Link DR, Kaplan PD, Stone HA, Weitz DA (2005) Monodisperse double emulsions generated from a microcapillary device. Science 308:537

Utada AS, Nieves AF, Stone HA, Weitz DA (2007) Dripping to jetting transitions in coflowing liquid streams. Phys Rev Lett 99:094502

Utada AS, Nieves AF, Gordillo JM, Weitz DA (2008) Absolute instability of a liquid jet in a coflowing stream. Phys Rev Lett 100:014502

van der Graaf S, Schroën CGPH, van der Sman RGM, Boom RM (2004) Influence of dynamic interfacial tension on droplet formation during membrane emulsification. J Colloid Interface Sci 277:456–463

Vladisavljevic GT, Shahmohamadi H, Das DB, Ekanem EE, Tauanov Z, Sharma L (2014) Glass capillary microfluidics for production of monodispersed poly (DL-lactic acid) and polycaprolactone microparticles: experiments and numerical simulations. J Colloid Interface Sci 418:163–170

Walters TW (1988) Drop formation in liquid–liquid systems. Exp Fluids 7(3):210–213

Wang W, Ngan KH, Gong J, Angeli P (2009) Observations on single drop formation from a capillary tube at low flow rates. Colloids Surf A 334(1–3):197–202

Yang X (2007) Nano- and microparticle-based imaging of cardiovascular interventions: overview 1. Radiology 243:340–347

Yildirim OE, Xu Q, Basaran OA (2005) Analysis of the drop weight method. Phys Fluids 17:062107

Zhang X (1999) Dynamics of drop formation in viscous flows. Chem Eng Sci 54:1759–1774

Zhang XG, Basaran OA (1995) An experimental-study of dynamics of drop formation. Phys Fluids 7:1184–1203

Zhang DF, Stone HA (1997) Drop formation in viscous flows at a vertical capillary tube. Phys Fluids 9:2234

Zhao CX, Millar E, Cooper-White JJ, Middelberg APJ (2011) Effects of fluid–fluid interfacial elasticity on droplet formation in microfluidic devices. AIChE J 57:1669–1677

Acknowledgments

We acknowledge Engineering and Physical Sciences Research Council (EPSRC) for providing the high-speed video camera on loan for the experiment.

Author information

Authors and Affiliations

Corresponding author

Appendix: Derivation of surface-average age (t av) of a growing spherical drop

Appendix: Derivation of surface-average age (t av) of a growing spherical drop

We assume the drop is always spherical while growing at the tip of the channel. Q is the constant volumetric flow rate feeding the drop; A is the surface area of the drop having radius r at any time t.

The interface created at the beginning of the drop formation has the longest age, which is equivalent to the time of drop formation t f. Similarly, the surface generated at the point of drop detachment has the shortest (zero) surface age. Thus, the surface-average age of a drop, which is eventually ruptured at t f with volume V f, area A f and radius r f, can be expressed by,

Note that the surface-average age of the drop is independent of volumetric flow rate.

Rights and permissions

About this article

Cite this article

Chaurasia, A.S., Josephides, D.N. & Sajjadi, S. Buoyancy-driven drop generation via microchannel revisited. Microfluid Nanofluid 18, 943–953 (2015). https://doi.org/10.1007/s10404-014-1484-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-014-1484-x