Abstract

Modification of the surfaces of polycarbonate (PC) with the use of a solution of tin (II) chloride renders them hydrophilic. The surface draping is stable against exposure to water and to alcohols. Exposure to alkanes reduces but does not diminish the effect. The method is compatible—in using the same solvent and temperature—with the hydrophobic modification of PC Jankowski et al. ( Lab Chip 11:748–752, 2011). The combination of these methods makes it possible to generate single and multiple monodisperse emulsions with the use of flow-focusing junctions in systems made in PC—material that is suitable for fabrication of multilayer, high throughput microfluidic devices.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

We report a new technique for modification of surfaces of polycarbonate that yields these surfaces hydrophilic. Our method uses tin (II) chloride. The procedure is compatible (i.e. in using the same solvent and temperature) with the hydrophobic modification of PC (Jankowski et al. 2011). This compatibility makes it possible to produce microdevices comprising both hydrophilic and hydrophobic regions needed, e.g., to generate multiple emulsions. The presented method of modification of PC can be also useful for ‘‘Lab-on-a-chip’’ systems, e.g., for ‘‘Lab-on-a-CD’’. The hydrophilic surface of centrifugal microfluidic platforms, which have the potential to become a standard tool for mainstream diagnostics, allows to change surface tension and can improve the efficiency and cost-effectiveness of the processes (Gorkin et al. 2010). The ability to perform these modifications in PC is important because PC is one of materials that (1) allow for facile construction of multilayered systems for parallel (i.e. high throughput) formation of emulsions and (2) are compatible with mass production via injection molding. The disadvantage of PC is its poor chemical resistance to most organic solvents. Although PC is compatible with a wide range of organic oils (including hexadecane, silicone oils, mineral oils, and fluorocarbons), it is incompatible with aggressive solvents (e.g., acetone, benzene, or dichloromethane). Concentrated acids and bases destroy the surface of native PC via hydrolysis of the carbonate bonds. Only a handful of solvents can be used, including, water, dilute solutions of acids and bases, alcohols and cyclohexane (Jankowski et al. 2012).

Double emulsions comprise droplets encapsulated in immiscible liquid shells, as, e.g., water drops in organic shell in a continuous aqueous phase (W/O/W) or an oil droplet inside an aqueous shell suspended in a continuous oleic phase (O/W/O). Double emulsions are useful in medicine (especially in drug delivery) (Davis and Walker 1987; Nakano 2000; Vasiljevic et al. 2006;), biology (Kelly et al. 2007), cosmetology (Yoshida et al. 1999; Lee et al. 2001) and food industry (Weiss et al. 2005; Lobato-Calleros et al. 2006; Muschiolik 2007). The uses in medicine and cosmetology typically center around encapsulation of active substances inside double emulsions for targeted drug delivery and for control of the temporal profile of their release. Conventional (bulk) schemes of generation of double emulsions present numerous challenges, making it particularly difficult or impossible to control the number of embedded droplets and the distribution of volumes of the cores and shells (Muschiolik 2007; Nakashima et al. 2000; Van der Graaf et al. 2005; Vasiljevic et al. 2006).

Such control is readily available via the use of microfluidic devices that form emulsions one droplet at a time (Muschiolik 2007; Engl et al. 2008; Shah et al. 2008). The use of microfluidic devices to formulate double emulsions yields an easy and unlimited ability to design the size and number of embedded droplets (Wang et al. 2011) and to place distinct surfactants at each of the interfaces which can be used to increase their stability. Generation of double emulsions imposes specific requirements on the design of the microfluidic chips. In particular, in planar designs, it is necessary for the devices to comprise both hydrophilic and hydrophobic sections of the channels. This can be realized in two ways: by proper selection of hydrophilic and hydrophobic materials (Shah et al. 2008) that are later snapped together to form the heterogeneously wettable device and to use one kind of polymer—or more generally one material—to build the chip and then to modify selected regions of the microchannels using appropriate chemistry (Okushima et al. 2004; Nisisako et al. 2005; Abate et al. 2008, 2010; Bauer et al. 2010). For example, Nisisako et al. (2005) presented a glass microfluidic device with serially connected hydrophobic and hydrophilic microchannels to form aqueous and organic drops consecutively. A hydrophobic channel was prepared using a silane-coupling agent. Abate et al. (2010) proposed both hydrophobic and hydrophilic modifications of monolithic microchannels fabricated in PDMS using polyacrilic acid and photoreactive sol–gel mixture containing fluorosilane. Bauer et al. (2010) used sequential layer-by-layer deposition of polyelectrolytes yielding hydrophilic microchannels in PDMS-based microfluidic devices. PDMS is a material of choice in academic use, yet industries typically use thermoplastics that can be mass-produced by injection molding. This motivates the search for appropriate schemes of modification of the surface chemistries of popular plastics. We have recently developed two methods to modify polycarbonate: one that coats the polymer with dodecylamine (DDA) to render a hydrophobic and lipophylic surface (Jankowski et al. 2011) and another for sequential deposition of electrolytes to render PC hydrophilic (lipophobic) (Derzsi et al. 2011). These two methods, however, although suitable for production of single emulsions are not fully compatible with protocols for heterogeneous modifications. The coating with polyelectrolytes requires multiple operations of sequential flushing with different solutions. Each of the changes of the solution requires equalization of pressures and flow to avoid undesired cross-modification of the regions of the chips. A procedure involving multiple such operations would be prohibitively difficult in execution.

Here we demonstrate a method for rendering PC hydrophilic in a procedure that is compatible with the hydrophobic draping of PC with DDA. We first detail the procedure of the new modification with tin (II) chloride and then demonstrate a microfluidic system suitable for production of (O/W) and (W/O/W) emulsions.

2 Experimental

2.1 Materials

We used tin (II) chloride (Sigma-Aldrich, Germany), dodecylamine (Sigma-Aldrich, Germany) and ethanol (Chempur, Poland) to modify the surface of polycarbonate (Bayer, Germany). All chemicals were of analytical grade and were used without further purification. For preparation of aqueous solutions, we used doubly distilled water (Milipore, 18 MΩ).

2.2 Fabrication of the chips

Fabrication of the chips in PC (Makrolon, Bayer) included micromilling of PC plates (Ergwind MSG4025, Poland) and bonding them (Ogończyk et al. 2010). We found it critical that the channel surfaces were well cleaned prior to modification. For this purpose, we cleaned the PC plates in an ultrasonic cleaner in isopropanol for 1 h at 40 °C before bonding.

2.3 Procedure for surface modification

20 % (w/w) ethanolic solution of SnCl2 was introduced into the microchannels and passed through them for 2 h (at a flow rate of 4 mL/h for channels of 400 × 400 μm cross-section). During the process of modification, the microdevice was thermostated at 60 °C. After flushing the channels with water (5 mL/h) for 20 min at room temperature the devices were ready to use. The life-span of the modification can be increased by storing the chips with microchannels filled with water.

2.4 Surface analysis

The XPS spectra were recorded on a PHI 5000 VersaProbe™ scanning ESCA Microprobe using monochromatic Al-Kα radiation (hν = 1,486.6 eV) from an X-ray source operating at 200 μm spot-size, 50 W and 15 kV. Elemental quantification was done using CasaXPS ver. 2316 software.

2.5 Contact angle measurements

Contact angle (CA) measurements were done with the use of a static sessile drop method. In the case of CA of water in air (water/PC/air) we took images of a 2 μL droplet of distilled water on the surface. We also measured the CAs of hexadecane in surrounding water (oil/PC/water) by placing the PC plates in a reservoir filled with distilled water and putting a droplet of hexadecane on the plate from underneath, using a syringe and a 100 μm internal diameter capillary. We used a camera (UI-1120SE, uEye, Germany) to record the shape of the droplet and measured the value of the CA with ImageJ (Fiji).

3 Results and discussion

3.1 Nature of the hydrophilic modification

Tin (II) chloride (SnCl2) is known as an effective catalyst for thermal decomposition of polycarbonate. It is characterized by extremely strong activity of degradation (Chiu et al. 2006). We observed that treatment of PC with a solution of tin (II) chloride in ethanol at elevated temperatures yields a strongly hydrophilic surface. We found that there is a close correlation between the contact angles of water on the plate in air and the content of tin in the surface layer of modified PC (Fig. 1).

XPS analysis was used to verify this assertion and results are presented in Table 1 and Fig. 2. The analysis of the O 1 s XPS spectra revealed that in addition to oxides also hydroxide compounds were detected. This confirms the assertion that the hydrophilic character is likely associated with the presence of SnO·nH2O on the modified surface (Table 1).

Top row: the analysis of high-resolution XPS spectra of Sn 3d (left) and O 1 s (right) recorded on PC surface after modification with SnCl2 (10 weight % ethanolic solution of SnCl2 at 70 °C, 2 h). Below, for comparison, the analysis of the corresponding spectra for SnO, SnO after 1 min Ar+ sputtering and SnO2

To finally confirm the chemical state of tin oxide on the surface, we compared the XPS spectra of the modified surfaces of PC with the corresponding XPS spectra obtained for commercially available (Alfa Aesar GmbH), standard samples of SnO and SnO2 (Fig. 2). The BE values detected for XPS states of tin (II) and tin (IV) oxides indicate SnO to be the dominant form of tin compounds on the modified PC. The surface layer of the standard SnO sample was partially contaminated by SnO2, which was removed after 1 min Ar+ sputtering (Fig. 2). The results allow us to conclude that the surface modification of PC with SnCl2 yields the surface draped with SnO with the atomic content of tin in excess of 20 % (Table 1).

Interestingly, none of the other metal chlorides (MgCl2, ZnCl2, AlCl3 and SnCl4) that we tested under similar conditions for modification of polycarbonate increased the hydrophilic character of the surface.

3.2 Optimization of the procedure

We have varied a number of parameters of the procedure of draping polycarbonate with SnO to find possibly optimum conditions. For each type of modification, we first inspected the quantitative content of tin atoms on modified plates of PC using XPS. We also measured the contact angles of water on these plates. Then, we repeated the experiments to modify the surface of microchannels in preassembled chips.

The most general finding of all these experiments is that the higher amount of tin on the modified surface makes the lower values of the contact angles of water (Fig. 1). We selected ethanol as a solvent because of good solubility of tin (II) chloride and because it is also used in the procedure of rendering PC hydrophobic by draping it with dodecylamine (Jankowski et al. 2011). In the screens of parameters of modification, we found that the content of tin in the modified surface area depends on the concentration of tin (II) chloride in the solution (Fig. 3a). The atomic concentration (AC) of tin on the surface increases with concentration of the solution and saturates at the coverage of approximately 25 % of tin at the surface of a modified PC for solutions of concentration of 10 % (w/w) or higher. Nonetheless, in modifications of the surfaces of microchannels we often continued to use a 20 % solution of SnCl2 to make sure that all the nooks in the corners of the milled channels are saturated with the salt.

Atomic content of tin (filled circles) and the contact angle (open circles) of water on modified PC as a function of a the concentration of SnCl2, b the temperature at which modification was conducted and c the duration of the modification reaction. The standard conditions (unless changed as indicated in the graph) comprised modification of 0.75 mm thick plates of PC by immersion in a stirred 20 % (w/w) solution of SnCl2 in ethanol at 70 °C for 2 h

We found that the quality of the modification depends strongly on the temperature at which modification was done (Fig. 3b). To get a sufficiently large concentration of tin on the surface of PC it is necessary to conduct the modification at relatively elevated temperatures (≥60 °C). Finally, the interval over which the surfaces are exposed to the solution of tin chloride should not be <1 h (Fig. 3c). We found that in the case of modifications of microchannels it is optimum to conduct the procedure for 2 h. Increasing the interval more does not result in any further improvement of the modification. In conclusion, we determined the best set of conditions comprising \( C_{{{\text{SnCl}}_{2} }} = 20\,\% \) (w/w) in ethanol, T = 70 °C and t = 2 h.

3.3 Stability of the modification

It is well known that the surface properties may deteriorate (or simply change) over time of exposure of the surface to various media. The stability of the coating and of the desired character of the surface is one of the more important criteria in a judgment of applicability of any method to either academic or industrial use.

We tested the evolution of the CA of water on the treated planar substrates of PC. In all these trials, we used the optimized procedure of modification: we used 20 × 40 mm PC plates of a thickness of 0.75 mm. Cleaned PC plates were swelled in vacuum with dichloromethane vapors and heated in an oven at 130 °C for 30 min prior to use to mimic the conditions of the sealing process (Ogończyk et al. 2010). Then we treated them with a 10 % (w/w) ethanol solution of SnCl2 at 70 °C for 2 h and then thoroughly washed with water and dried with pressurized air.

To quantify the stability of the hydrophilic character of the modified surfaces, we immersed each set of substrates in one of four different media: two hydrophobic (air and hexadecane) and two polar (water and isopropanol). Then, at various instants over the course of 3 weeks we took the plates out, dried with pressurized air (and in the case of immersion in hexadecane, first thoroughly washed with ethanol). Finally, the contact angles of water on the substrate in air, and of hexadecane on the substrate immersed in water were measured.

Figure 4 graphs the CAs of water on the modified PC substrates. The plates that were exposed to polar solvents sustained the hydrophilic character with typical values of the CA of water in air equal ca. 15°–20° for samples exposed to water and 10°–15° for plates exposed to isopropanol. These values did not show any statistically significant change over the course of the 3 weeks of the experiment. Exposure of the plate to hexadecane immediately shifts the CA of water to values typical to slightly hydrophilic substrates (ca. 70°) and stabilized at this value. The value of the CA of water on the plates exposed to the atmospheric air showed slow recovery of the original hydrophobic character.

In microfluidic applications comprising formation of droplets of oil in water in the microchannels, it is necessary to use a surface that is not only hydrophilic but also lipophobic. For example, the hydrophilic surface of PC after exposition to oxygen plasma or UV is equally well wetted by water and by oil and thus cannot serve the purpose. Thus, in order to verify the applicability of the modified surfaces to formation of O/W emulsions, we measured the contact angles of oil (hexadecane) drops deposited on the modified plates in the continuous phase of water (Fig. 5). The native (untreated) polycarbonate is lipophilic, with the CA of hexadecane in water (oil/PC/water) equal to ca. 40°. In a stark contrast, the treated substrate, immediately after the modification yielded CA of hexadecane in water exceeding 150°. Exposure of the substrates to air or hexadecane slightly deteriorated this lipophobic character, decreasing the CA of hexadecane in water to 120°–125°. Exposure to either water or isopropanol preserved the strongly lipophobic character with the CAs of oil on the plates in excess of 150°. We note that these values may be even higher: droplets of hexadecane were freely rolling on the modified plates immersed in water.

Contact angle of water in atmospheric air environment (water/PC/air) and of hexadecane in surrounding water (oil/PC/water). The volume of water droplets was 2 μL, oil droplets were produced by spontaneous breakup from a steel capillary (ID = 100 μm) based on the principle used pedant drop technique. The capillary was placed under the PC substrates in water bath and was connected to a syringe of a small diameter (ID = 4.7 mm). The oil was injected manually via the syringe and controlled optically. The volume of the droplets was 11.95 μL with repeatability of CV = 4.2 %, (defined as CV = (σ V/V) × 100 %, where CV is the coefficient of variation, σ V is the standard deviation of the volume of the droplets, V is the mean volume of the droplets). Left row text indicates the solvent in which the PC plates were immersed for up to 3 weeks before taken out and dried prior to the water/PC/air and oil/PC/water CA measurement. ‘Native’ is unmodified PC plate

3.4 Formation of single organic droplets in water

We tested the applicability of the modification to microfluidic generation of O/W emulsions. We used a standard cross-junction chip with all the channels having square 400 × 400 μm cross-sections. We tested the formation of droplets of hexadecane, FC-40 (Fluorinert), silicone oil and soya oil, all in the continuous phase of water (Fig. 6). For all types of oils, we did not observe any evidence of wetting of the modified surface by the oil phase in the experiments conducted over a period longer than 8 h each.

3.5 Fabrication of chips for generation of double emulsions

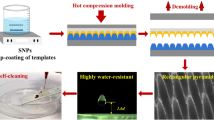

The method that we described can be used to prepare microfluidic chips for generation of double emulsions. Such a system should have sections of channels presenting hydrophilic (and—at the same time— lipophobic) character and sections that are hydrophobic (and lipophylic) (Bauer et al. 2010). Figure 7a shows the schematic diagram of the double cross-junction systems designed to generate W/O/W emulsions.

a Schematic diagrams of the double cross junctions for generation W/O/W double emulsions together with a schematic view of the whole chip for formation of W/O/W drops. The chip was 4.5 cm long and 2 cm wide. The cross-section of the microchannels was 400 × 400 μm. b Scheme of the modification procedure showing the distribution of flow during the first and second modification. c Micrograph showing an example of double droplets of water in hexadecane [with 1 % (w/w) of Span 80] in water

As an example, we fabricated a chip for generation of W/O/W double droplets. For generation of O/W/O, all the regions of different wettability should simply be inverted. In the system that we fabricated (for generation of W/O/W emulsions), the channel between the first and the second cross-junction has to have hydrophobic character and the channel between second cross-junction and the outlet needs to be hydrophilic.

To prepare these selective wettabilities, we need to use two modifications: one that we described here that generates a hydrophilic surface, and second that drapes the surface of PC with dodecylamine to render it hydrophobic (Jankowski et al. 2011). Simultaneous execution of these two protocols proved impossible because of precipitation of complexes [SnCl2]·[H2NC12H25] or [SnCl2]·[H2NC12H25]2 at the interface of the streams carrying solutions of dodecylamine and tin chloride. Because both of the procedures use the same solvent, we could use ethanol to prime the surface before the first modification, to wash the system before the second step and to use the same (pure) solvent as a blocking agent that prevents modification or contamination of the regions that are not to be modified within the first or second step. During the exchange of the syringe with ethanol with the syringe with solution of tin chloride (inlet 2), ethanol is continuously passed through an inlet 1 to prevent the SnCl2 solution entering to the hydrophobic part of the channel. This is sufficient to keep the coating agent away from the surfaces that we do not wish to modify. In the first stage, we introduced the hydrophobic character to a section of channels by passing a 5 % (w/w) solution of DDA from inlet 1 and pure ethanol from inlet 2 (Fig. 7b). Both liquids were passed through the channels at the same rate of 4 mL/h at 60 °C for 2 h. Then, we washed the device with pure ethanol for 15 min (4 mL/h). In the second step of modification, we run a 20 % (w/w) solution of SnCl2 in ethanol (at 3 mL/h, via inlet 2) and pure ethanol (3 mL/h, inlet 1) for 2 h at 60 °C. For practical reasons, we decided to use the same temperature for both modifications to run them quickly one after the other in the same temperature bath. As 70 °C degrades the surface of PC in the DDA treatment (Jankowski et al. 2011) we decided to use 60 °C to run the two modifications. Next the chip was removed from the thermostat and allowed to cool while the liquids continued to flow through to preserve the selective exposure of the walls to tin chloride. When the temperature decreased to room temperature, we washed the channels with water (5 mL/h, inlets 1 and 2) for 30 min. We stored the chip with channels filled with water. Reverse sequence modification is also possible, but requires additional steps. After reaction with SnCl2, the device should be cooled to room temperature, the channels flushed with water dried and then again placed in a thermostat for further modification with DDA. It should be noted that the modification with SnCl2 is more sensitive and, therefore, better results are obtained by performing it as a final step. Figure 7c shows an exemplary micrograph of the selectively modified double cross-junction producing double W/O/W droplets.

4 Conclusion

In this report, we have detailed a new method of modification of polycarbonate. Treatment of PC with an ethanolic solution of tin (II) chloride at elevated temperatures gives the surface strong hydrophilic properties. These properties are stable and can withstand weeks of storage in polar solvents. Storage in non-polar fluids reduces the originally strong hydrophilic character to slightly hydrophilic properties.

The hydrophilic modification of PC can be used to fabricate chips for generation of oil in water emulsions of alkanes (e.g., hexadecane), natural oils (e.g., soya oil), fluorocarbons (e.g., Fluorinert FC-40), and silicones (e.g., PDMS).

To the best of our knowledge, this is the first demonstration of selective modification of PC to render sections of this material hydrophilic and other regions hydrophobic. The fact that the two modifications (using SnCl2 and dodecylamine) are, respectively, also lipophobic and lipophobic makes the procedure ideal for fabrication of microfluidic chips dedicated to controlled generation of double emulsions. The proposed method is convenient in that it requires a single step for the hydrophilic modification and only two steps for the heterogeneous draping of PC. Both procedures use readily available and inexpensive reagents.

The important point to note is that we found it critical that the surfaces of native PC are properly cleaned before the modification with SnCl2. We have also found that PC from other sources not always modified equally reproducibly—unknown additives to the commercial brands of PC may interfere with the procedure.

Finally, the fact that the method uses PC as a substrate makes it potentially applicable to both academic and industrial uses in controlled generation of double emulsions and in preparative applications for targeted or controlled release of active substances in pharma, cosmetic and food industries.

References

Abate AR, Krummel AT, Lee D, Marquez M, Holtze C, Weitz DA (2008) Photoreactive coating for high-contrast spatial patterning of microfluidic device wettability. Lab Chip 8:2157–2160

Abate AR, Thiele J, Weinhart M, Weitz DA (2010) Patterning microfluidic device wettability using flow confinement. Lab Chip 10:1774–1776

Bauer WAC, Fischlechner M, Abell C, Huck WTS (2010) Hydrophilic PDMS microchannels for high-throughput formation of oil-in-water microdroplets and water-in-oil-in-water double emulsions. Lab Chip 10:1814–1819

Chiu SJ, Chen SH, Tsai CT (2006) Effect of metal chlorides on thermal degradation of (waste) polycarbonate. Waste Manage (Oxford) 26:252–259

Davis SS, Walker IM (1987) Multiple emulsions as targetable delivery systems. Methods Enzymol 149:51–64

Derzsi L, Jankowski P, Lisowski W, Garstecki P (2011) Hydrophilic polycarbonate for generation of oil in water emulsions in microfluidic devices. Lab Chip 11:1151–1156

Engl W, Backov R, Panizza P (2008) Controlled production of emulsions and particles by milli- and microfluidic techniques. Curr Opin Colloid Interface Sci 13:206–216

Gorkin R, Park J, Siegrist J, Amasia M, Lee BS, Park JM, Kim J, Kim H, Madou M, Cho YK (2010) Centrifugal microfluidics for biomedical applications. Lab Chip 10:1758–1773

Jankowski P, Ogonczyk D, Kosinski A, Lisowski W, Garstecki P (2011) Hydrophobic modification of polycarbonate for reproducible and stable formation of biocompatible microparticles. Lab Chip 11:748–752

Jankowski P, Ogończyk D, Lisowski W, Garstecki P (2012) Polyethyleneimine coating renders polycarbonate resistant to organic solvents. Lab Chip 12:2580–2584

Kelly BT, Baret JC, Taly V, Griffiths AD (2007) Miniaturizing chemistry and biology in microdroplets. Chem Commun 1773–1788

Lee MH, Oh SG, Moon SK, Bae SY (2001) Preparation of Silica Particles Encapsulating Retinol Using O/W/O Multiple Emulsions. J Colloid Interface Sci 240:83–89

Lobato-Calleros C, Rodriguez E, Sandoval-Castilla O, Vernon-Carter EJ, Alvarez-Ramirez J (2006) Reduced-fat white fresh cheese-like products obtained from W1/O/W2 multiple emulsions: viscoelastic and high-resolution image analyses. Food Res Int 39:678–685

Muschiolik G (2007) Multiple emulsions for food use. Curr Opin Colloid Interface Sci 12:213–220

Nakano M (2000) Places of emulsions in drug delivery. Adv Drug Deliv Rev 45:1–4

Nakashima T, Shimizu M, Kukizaki M (2000) Particle control of emulsion by membrane emulsification and its applications. Adv Drug Deliv Rev 45:47–56

Nisisako T, Okushima S, Torii T (2005) Controlled formulation of monodisperse double emulsions in a multiple-phase microfluidic system. Soft Matter 1:23–27

Ogończyk D, Węgrzyn J, Jankowski P, Dąbrowski B, Garstecki P (2010) Bonding of microfluidic devices fabricated in polycarbonate. Lab Chip 10:1324–1327

Okushima S, Nisisako T, Torii T, Higuchi T (2004) Controlled production of monodisperse double emulsions by two-step droplet breakup in microfluidic devices. Langmuir 20:9905–9908

Shah RK, Shum HC, Rowat AC, Lee D, Agresti JJ, Utada AS, Chu LY, Kim JW, Fernandez-Nieves A, Martinez CJ, Weitz DA (2008) Designer emulsions using microfluidics. Mater Today 11:18–27

Van der Graaf S, Schroën CGPH, Boom RM (2005) Preparation of double emulsions by membrane emulsification—a review. J Membr Sci 251:7–15

Vasiljevic D, Parojcic J, Primorac M, Vuleta G (2006) An investigation into the characteristics and drug release properties of multiple W/O/W emulsion systems containing low concentration of lipophilic polymeric emulsifier. Int J Pharm 309:171–177

Wang W, Xie R, Ju XJ, Luo T, Liu L, Weitz DA, Chu LY (2011) Controllable microfluidic production of multicomponent multiple emulsions. Lab Chip 11:1587–1592

Weiss J, Scherze I, Muschiolik G (2005) Polysaccharide gel with multiple emulsion. Food Hydrocolloids 19:605–615

Yoshida K, Sekine T, Matsuzaki F, Yanaki T, Yamaguchi M (1999) Stability of vitamin a in oil-in-water-in-oil-type multiple emulsions. J Am Oil Chem Soc 76:1–6

Acknowledgments

Project operated within the Foundation for Polish Science Team Programme co-financed by the EU European Regional Development Fund. The research was partially supported by the European Union within European Regional Development Fund, through an Innovative Economy grant (POIG.01.01.02-00-008/08).

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s10404-013-1315-5.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Jankowski, P., Ogończyk, D., Derzsi, L. et al. Hydrophilic polycarbonate chips for generation of oil-in-water (O/W) and water-in-oil-in-water (W/O/W) emulsions. Microfluid Nanofluid 14, 767–774 (2013). https://doi.org/10.1007/s10404-012-1090-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-012-1090-8