Abstract

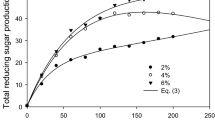

The present study deals with submerged ethanol, citric acid, and α-amylase fermentation by Saccharomyces cerevisiae SDB, Aspergillus niger ANSS-B5, and Candida guilliermondii CGL-A10, using date wastes as the basal fermentation medium. The physical and chemical parameters influencing the production of these metabolites were optimized. As for the ethanol production, the optimum yield obtained was 136.00 ± 0.66 g/l under optimum conditions of an incubation period of 72 h, inoculum content of 4% (w/v), sugars concentration of 180.0 g/l, and ammonium phosphate concentration of 1.0 g/l. Concerning citric acid production, the cumulative effect of temperature (30°C), sugars concentration of 150.0 g/l, methanol concentration of 3.0%, initial pH of 3.5, ammonium nitrate concentration of 2.5 g/l, and potassium phosphate concentration of 2.5 g/l during the fermentation process of date wastes syrup did increase the citric acid production to 98.42 ± 1.41 g/l. For the production of α-amylase, the obtained result shows that the presence of starch strongly induces the production of α-amylase with a maximum at 5.0 g/l. Among the various nitrogen sources tested, urea at 5.0 g/l gave the maximum biomass and α-amylase estimated at 5.76 ± 0.56 g/l and 2,304.19 ± 31.08 μmol/l/min, respectively after 72 h incubation at 30°C, with an initial pH of 6.0 and potassium phosphate concentration of 6.0 g/l.

Similar content being viewed by others

References

Abdulrahman M, Al-Shehri A, Yasseer S (2006) Citric acid production from date syrup using immobilized cells of Aspergillus niger. Biotechnol 5:461–465

Anonymous (2006) Palmiers dattiers, superficies. In: Agricultural Statistics Direction of the Algerian Agricultural Ministry (A.S.D.A.M) (ed) Statistiques Agricoles, Série B, Alger, pp 42–44

Anto H, Trivedi UB, Patel KC (2006) Glucoamylase production by solid-state fermentation using rice flake manufacturing waste products as substrate. Bioresour Technol 97(10):1161–1166

Arzumanov TE, Shishkanva NV, Finogenova TV (2000) Biosynthesis of citric acid by Yarrowia lipolytica repeat-batch culture on ethanol. Appl Microbiol Biotechnol 53:525–529

Asad UR, Sikander A, Iqram UH (2002) Temperature optima for citric acid accumulation by Aspergillus niger. Biotechnol 1:108–110

Asad UR, Sikander A, Iqram UH (2003) Phosphate limitation for enhanced citric acid fermentation using Aspergillus niger mutant UV-M9 on semi-pilot scale. Pak J Biol Sci 6:1247–1249

Bernfeld P (1955) Amylase, α/β. In: Colowick SP, Kaplan NO (eds) Methods in enzymology, vol 1. Academic Press, New York, pp 149–154

Bohlscheid JC, Fellman JK, Wang XD, Ansen D, Edwards CG (2007) The influence of nitrogen and biotin interactions on the performance of Saccharomyces in alcoholic fermentations. J Appl Microbiol 102:390–400

Botton B, Bretton A, Fever M, Gautier S, Guy PH, Larpent JP, Reymond P, Sanglier JJ, Vayssier Y, Veau P (1990) Moisissures utiles et nuisibles, importance industrielle. Masson, Paris

Caceres-Farfan M, Lappe P, Larque-Saavedra A, Magdub-Mendez A, Barahona-Perez L (2008) Ethanol production from henequen (Agave fourcroydes Lem.) juice and molasses by a mixture of two yeasts. Biores Technol 99:9036–9039

Cazetta ML, Celligoi MA, Buzato JB, Scarmino IS (2007) Fermentation of molasses by Zymomonas mobilis: effects of temperature and sugar concentration on ethanol production. Biores Technol 98:2824–2828

Cherry HM, Towhid-Hossain MD, Anwar MN (2004) Extracellular glucoamylase from the isolate Aspergillus fumigatus. Pak J Biol Sci 7:1988–1992

Crolla A, Kennedy KJ (2001) Optimization of citric acid production from Candida lipolytica Y-1095 using n-paraffin. J Biotechnol 89:27–40

Demirel G, Yaykasli KO, Yasar A (2005) The production of citric acid by using immobilized Aspergillus niger A-9 and investigation of its various effects. Food Chem 89:393–396

Dharani-Aiyer PV (2004) Effect of C:N ratio on alpha amylase production by Bacillus licheniformis SPT 27. Afr J Biotechnol 3(10):519–522

Djekrif-Dakhmouche S, Gheribi-Aoulmi Z, Meraihi Z, Bennamoun L (2006) Application of a statistical design to the optimization of culture medium for a-amylase production by Aspergillus niger ATCC 16404 grown on orange waste powder. J Food Eng 73:190–197

Gangadharan D, Sivaramakrishnan S, Nampoothiri KM, Pandey A (2006) Solid culturing of Bacillus amyloliquefaciens for α-amylase production. Food Technol Biotechnol 44:269–274

Guillen-Moreira F, Arrias de Lima F, Fazzano-Pedrinho SR, Lenartovicz V, Giatti-Marques de Souza F, Peralta RM (1999) Production of amylases by Aspergillus tamarii. Rev Microbiol 30(2):1–9

Guiraud J, Galzy P (1980) L’analyse microbiologique dans les industries alimentaires. L’usine nouvelle, Paris

Gupta R, Gigras P, Mohapatra H, Goswami VK, Chauhan B (2003) Microbial α-amylases: a biotechnological perspective. Proc Biochem 38:1599–1616

Hawksworth DL, Kirk PM, Sutton B, Pegler DN (1995) Ainsworth and Bisby’s dictionary of the fungi, 8th edn. Commonwealth Mycological Institute, CABI Publishing, United Kingdom

Hernandez MS, Rodrıguez MR, Perez-Guerra N, Perez-Roses R (2006) Amylase production by Aspergillus niger in submerged cultivation on two wastes from food industries. J Food Eng 73:93–100

Ikram UH, Sikander A, Qadeer MA, Javed I (2003) Stimulatory effect of alcohols (methanol and ethanol) on citric acid productivity by a 2-deoxy d-glucose resistant culture of Aspergillus niger GCB-47. Biores Technol 86:227–233

Kaur P, Grewal HS, Kocher GS (2003) Production of a-amylase by Aspergillus niger using wheat bran in submerged and solid-state fermentations. Indian J Microbiol 43:143–145

Kunameni A, Permaul K, Singh S (2005) Amylase production in solid-state fermentation by the thermophilic fungus Thermomyces lanuginosus. J Biosci Bioeng 100:168–171

Lagzouli M, Charouf R, El-Yachioui O, Berny MEH, Jadal M (2007) Optimisation de la croissance et de la production de gluco amylase extra cellulaire par Candida guilliermondii. Bull Soc Pharm 146:251–270

Monte-Alegre R, Rigo M, Joekes I (2003) Ethanol fermentation of a diluted molasses medium by Saccharomyces cerevisiae immobilized on chrysotile. Braz Arch Biol Technol 46:29–37

Nadeem AF, Syed Q, Baig S, Irfann A, Nadeem A (2010) Enhanced production of citric acid by Aspergillus niger M-101 using lower alcohols. Turkish J Biochem 35:7–13

Nawaz-Bhatti H, Hamid-Rashid M, Nawaz R, Asgher M, Perveen M, Abdul-Jabbar A (2007) Optimization of media for enhanced glucoamylase production in solid-state fermentation by Fusarium solani. Food Technol Biotechnol 45(1):51–56

Pandey A, Nigam P, Soccol CR, Soccol VT, Singh D, Mohan R (2000) Advances in microbial amylases. Appl Biotechnol Biochem 31:135–152

Papagianni M (2007) Advances in citric fermentation by Aspergillus niger: biochemical aspects, membrane, transport and modelling. Biotechnol Adv 25:244–263

Pavezzi FC, Gomes E, Roberto-Da-Silva R (2008) Production and characterization of glucoamylase from fungus Aspergillus awamori expressed in yeast Saccharomyces cerevisiae using different carbon sources. Braz J Microbiol 39(1):127–135

Pazouki M, Felse PA, Sinha J, Panda T (2000) Comparative studies on citric acid production by Aspergillus niger and Candida lipolytica using molasses and glucose. Bioproc Eng 22:353–361

Pocock KF, Rankine BC (1997) Measurement of the alcohol content of wine by gas chromatography. Aus Rev Wine Brewery Spirit 93:32–34

Pramanik K (2003) Parametric studies on batch alcohol fermentation using Saccharomyces yeast extracted from toddy. Chin J Inst Chem Eng 34:487–492

Saima K, Asad UR, Ambreen S, Sikander A, Kiran S, Ikram UH (2003) Nitrogen limitation for citrate accumulation by Yarrowia lipolytica NRRL-143 in shake flask. J Food Technol 1:157–159

Sikander A, Ikram HQ, Qadeer MA, Javed I (2002) Production of citric acid by Aspergillus niger using cane molasses in a stirred fermentor. Electronic J Biotechnol 5:114–125

Sindhu R, Suprabha GN, Shashidhar S (2009) Optimization of process parameters for the production of α-amylase from Penicillium janthinellum (NCIM 4960) under solid-state fermentation. Afr J Microbiol Res 3(9):498–503

Touzi A (1997) Production d’éthanol à partir des déchets de dattes. Revue de Recherche Agronomique d’Algérie 1:53–58

Walid AL, Khaled MG, Ehab RH (2006) Citric acid production by a novel Aspergillus niger isolate: optimization of process parameters through statistical experimental designs. Biores Technol 19:171–173

Wang Q, Wang X, Maa H (2008) Glucoamylase production from food wastes by Aspergillus niger under submerged fermentation. Process Biochem 43:280–286

Zaldivar-Aguero JM, Badino AC, Vilaça PR, Facciotti MCR, Schmide W (1997) Influence of phosphate concentration on gluco-amylase production by Aspergillus awamori in submerged culture. Braz J Chem Eng 14:104–108

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Acourene, S., Ammouche, A. Optimization of ethanol, citric acid, and α-amylase production from date wastes by strains of Saccharomyces cerevisiae, Aspergillus niger, and Candida guilliermondii . J Ind Microbiol Biotechnol 39, 759–766 (2012). https://doi.org/10.1007/s10295-011-1070-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-011-1070-0