Abstract

The deterioration of wood-based panels at eight sites in Japan over 7 years of outdoor exposure was investigated. In particular, the modulus of rupture (MOR) retention and internal bond strength (IB) retention after 7 years of exposure were compared among panels and sites. The deterioration of panels was greater in southern Japan than in northern Japan. The strength retentions in northern Japan decrease linearly, while those in southern Japan decreased exponentially. To quantify regional differences, deterioration rates were calculated based on three different weather conditions (precipitation, temperature, and sunlight hours), and the significance of each of these parameters on panel deterioration was determined. We found that the correlation coefficients between both IB and MOR retention and weathering intensity were the same whether we used 10-day, monthly, or daily weathering data.

Similar content being viewed by others

Introduction

In recent years, mat-formed wood-based panels have become widely used in residual construction in Japan. Wood-based panels can be made from recycled and unused wood. However, there is little information about the durability of such panels, and basic information on their long-term durability is important. Estimating how long a building material can maintain its required performance under actual environmental conditions has been the goal of many studies evaluating the durability of wood-based materials.

To evaluate the durability of wood-based panels, the Research Working Group on Wood-based Panels of the Japan Research Society has been conducting a project since 2004. The main component of this project is conducting outdoor exposure tests at eight sites in Japan, but indoor exposure tests and accelerated aging tests are also conducted. Previous papers have addressed thickness swelling [1], internal bond strength (IB) [2], and bending properties [3] after 5 years of outdoor exposure in Shizuoka City, along with the effects of accelerated aging treatment. In the present study, outdoor exposure tests began in April 2004 simultaneously at all eight sites. All samples (except those at one site, Tsukuba City) were tested in March 2011.

Because outdoor exposure tests are considered a test for accelerated aging based on natural environmental conditions, the deterioration mechanism was thought to be similar to the deterioration that occurs when wood-based panels are actually used in housing construction. But outdoor exposure tests have many disadvantages; one of the most significant is that results are limited by the test location [4]. Even when outdoor exposure tests use the same panels at all locations, there are differences in the deterioration of panels among the locations. Thus, the results of outdoor exposure tests conducted at specific sites are not applicable to sites with different weather conditions.

We attempted to eliminate regional differences in the deterioration of panels by defining “weathering intensity,” based on weather parameters [5, 6]. In previous studies, weathering intensity was defined as a weather-based force exerted on panels during outdoor exposure tests, considering only average daily temperature and daily precipitation as weather parameters. However, this method ignored other important factors that influence panel deterioration (e.g., sunlight hours), and calculations of daily parameters become cumbersome over a period of several years. Hence, to address these issues, the calculation of weathering intensity was modified as follows: considering temperature, precipitation, and sunlight hours as weathering parameters; calculating weathering intensity using data from the Japan Meteorological Agency’s website [7] without making any assumptions; calculating weathering intensity based on daily data, while exploring the use of 10-day and monthly averages to reduce the time spent on calculations; and calculating weathering intensity based on a combination of the three weather parameters while also exploring the relationships between weathering and both modulus of rupture (MOR) retention and IB retention.

Applying the above conditions, the effect of each individual weather condition on the deterioration of mat-formed wood-based panels over a 7-year outdoor exposure test was investigated.

Materials and methods

Sample panels

Four types of commercial wood-based panels were used: particleboard (PB), medium-density fiberboard (MDF), oriented strandboard (OSB), and plywood (PW); all are widely used for construction in Japan (Table 1). Each panel group included two panel types with different specifications for a total of eight panels. The PB panels were made from recycled wood with different binders. The MDF panels differed in thickness, binder type, and end-use application. The OSB panels were made from imported products of various wood species. The PW panels differed in thickness. Although North America has very little methyl diphenyl diisocyanate (MDI)-bonded PB or MDF, MDI-bonded PB and MDF were selected because fabricators in Japan show a strong preference for PB and MDF with the high durability performance offered by MDI. The original mechanical properties, MOR, modulus of elasticity (MOE), and IB of the panels prior to outdoor exposure tests are summarized in Table 1.

Outdoor exposure tests at eight sites in Japan

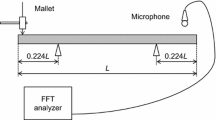

For each panel type, 12 test sample boards, each 300 mm × 300 mm, were subjected to outdoor exposure tests at eight sites in Japan: Asahikawa (43°N, 142°E), Morioka (39°N, 141°E), Noshiro (40°N, 140°E), Tsukuba (36°N, 140°E), Shizuoka (34°N, 138°E), Okayama (South; 34°N, 133°E), Okayama (North; 35°N, 133°E), and Miyakonojo (31°N, 131°E) [6]. In this paper, these eight sites were divided into two groups; northern Japan (Asahikawa, Morioka, Noshiro, and Tsukuba) and southern Japan (Shizuoka, Okayama North, Okayama South, and Miyakonojo). Annual average temperature, precipitation, sunlight hours, and climate classifications for each site are listed in Table 2. Monthly average temperatures, precipitation, and sunlight hours over 7 years are shown in Fig. 1. All four edges of each sample board were coated with a protective agent to prevent excessive edge swelling due to water contact during exposure. The boards were set vertically on a south-facing test frame. The tests began on March 2004 and continued until March 2011 (with the exception of the tests at Tsukuba). After 5 years of exposure all of the panels were removed for analysis. The following year (year 6) only panels with bending retentions or IB retentions that degraded to less than 50 % were removed. In year 7, the remaining panels were removed for testing.

After reconditioning at 20 °C and 65 % relative humidity (RH) for 2 weeks, IB and bending properties were measured. Eight bending samples with a dimension of 250 mm × 50 mm and 13 IB test samples (50 mm × 50 mm) were prepared from the reconditioned panels. The bending and IB tests were performed in accordance with JIS A-5908 [8] and were conducted using a universal testing machine (Model TCM-1000, Shinkoh).

Results and discussion

Characteristics of MOR and IB retention for 7-year outdoor exposure tests at eight sites

The MOR and IB for the control samples (untreated) are shown in Table 1. We defined the strength retentions as follows:

Figures 2 and 3 show the changes in retention of panels following 7 years of outdoor exposure tests in the eight regions. If the retention was greater than 100 %, we defined it as 100 % retention. To show the results clearly, these figures were divided into two graphs: northern Japan and southern Japan.

Figure 2 shows the change in MOR retention over time. The MOR retentions of the two PBs decreased linearly at all exposure sites. The decrease in MOR retention of PB(PF) was higher than that of PB(MDI). MOR retention of PB(PF) was less than 40 % after 6 years of exposure at all sites except for Noshiro. On the other hand, MOR retention of PB(MDI) remained higher than that of PB(PF). The MDFs maintained comparatively high MOR retentions at all sites for 7 years. The MOR retention of OSB(aspen) in Shizuoka and Miyakonojo were less than 50 % after only 1 year and were only 10 % after 6 years of exposure. For OSB(aspen), there were two patterns of decreasing MOR retention: retention linearly decreased at sites in northern Japan and exponentially decreased at sites in southern Japan. The MOR retention of OSB(pine) tended to decrease linearly for all regions. The variation among PWs was large, and any characteristic tendencies were unclear.

The measured IB retentions are shown in Fig. 3. The decrease in IB retention of PB(PF) was greater than that of PB(MDI); those of PB(PF) were less than 50 % after 1 year of exposure at Shizuoka and Miyakonojo and less then 50 % after 2 years of exposure in southern Japan. For PB(PF), there were two patterns of decreasing IB retention: it decreased linearly in northern Japan and decreased exponentially in southern Japan. MDFs maintained high IB retentions and bending properties at all sites. OSB(aspen) also displayed two patterns of decreasing IB retention: linearly in northern Japan and exponentially in southern Japan. For OSB(aspen), sites located in southern Japan had 50 % IB retention after 1 year; all sites had retention decline to 50 % or less after 5 years of exposure. For OSB(pine), the decrease in retention was high, and the IB retentions of panels located in southern Japan were less than 50 % after 4 years of exposure. However, PWs showed a wide variation in their retention range and did not show any identifiable pattern or tendency in IB retention over time.

Panel deterioration rate after 7 years of outdoor exposure

As shown in Figs. 2 and 3, the deterioration of panels varied among exposure sites. This was caused by different weather conditions (temperature, precipitation, hours of sunlight, etc.) at each site. To quantify these regional differences, we calculated the deterioration rate using a method introduced in one of our previous papers [6], calculated as y = −A × log(t) + B, where y is the strength retention, t is the number of months of outdoor exposure, and B is the intercept. Coefficient A was calculated using this equation on MOR and IB retentions at all eight sites (Figs. 4, 5). In these figures, the values of coefficient A for PB(PF) and OSB(aspen), in which deteriorations were the highest in eight panels, and MDF(MDI), in which deterioration was the smallest in the eight panels, were shown. As shown in Fig. 4, the deterioration rates for PB(PF) and OSB(aspen) were very high. In contrast, MDF(MDI) deteriorated the least in all panels, at a rate of approximately one-third that of OSB(aspen). In addition, there were differences in the deterioration rates of PB, MDF, and OSB among sites, being high at Shizuoka and Miyakonojo and low at Asahikawa and Noshiro.

Figure 5 shows the deterioration rates of IB retentions. Along with MOR retention, the deterioration rates of IB for PB(PF) and OSB(aspen) were the highest whereas those for MDF(MDI) were the lowest. The deterioration rate of OSB(aspen) was more than 10 times that of MDF(MDI). Deterioration rates also varied among sites, being higher in southern Japan than in northern Japan.

Correlation between weathering intensity and strength retentions

Generally speaking, mat-formed panels such as PB, MDF, and OSB experience decreases in mechanical properties due to panel swelling. Under outdoor exposure, we expected that temperature and precipitation would affect the cycle of swelling and drying, and that sunlight would affect the surface deterioration of panels. However, we found that weather affected panel deterioration more intricately. We calculated the weathering intensity based on temperature (T), precipitation (P), and sunlight hours (S) during the period of outdoor exposure, expressing weathering intensity as a sum of the weather factor itself (i.e., ∑T, ∑P, ∑S) or as a sum of weather parameter combinations [e.g., ∑(T × S), ∑(T × P), ∑(P × S), and ∑(T × P × S)]. Weathering intensity is required to measure the effects of each weather factor on panel deterioration. We used daily, 10-day, and monthly data for calculating weathering intensity, and explored correlations between panel deterioration and weathering intensity. Some sites did not have detailed weather data and therefore panel deterioration could be predicted only if the relationships between weathering intensity and deterioration using 10-day or monthly data were similar to those using daily data.

We used weather data from the Japan Meteorological Agency [7]. In a previous study [6], PB(PF) and OSB(aspen) deteriorated at all sites, and correlations between weathering intensity and strength retention were high. However, in the present study, PW and MDF panels maintained their strength properties during 7 years of outdoor exposure, so that the correlations between weathering intensity and strength retention were low.

MOR and IB retentions were measured over 7 years of outdoor exposure tests at eight sites to study weathering intensity. Weathering intensity was determined based on the coefficient of correlation from linear regression analysis to give a logarithm of weathering intensity for each panel. Figure 6 shows the relationship between calculated weathering intensity and the mechanical property retentions of PB(PF) as a cobweb chart, and Fig. 7 shows the relationship between calculated weathering intensity and the mechanical property retentions of OSB(aspen) as a cobweb chart. In terms of IB retention, the coefficient of correlation’s sum of S (log∑S), calculated using daily, 10-day, and monthly data, was lower than that of MOR retention. This implicates that sunlight hours as a factor positively related to panel surface deterioration, because IB is an interior property of panels, whereas MOR is a surface property. Using 10-day and monthly data, we found that the coefficients of correlation for relationships between ∑(P × S), ∑(T × P), and ∑(T × P × S) and IB retention were high, especially for ∑(T × P), and ∑(T × P × S). Based on these results, the best evaluation of weathering intensity results from a factor representing temperature multiplied by precipitation. This implies that temperature and precipitation have large effects of panel deterioration. The coefficients of correlation between ∑(P × S) and each retention were lower when using daily data than 10-day or monthly data. The reduced strength of this relationship when finer scale data were used may be the result of shortened sunlight hours occurring on rainy days, and vice versa. Therefore, we determined that the evaluation of panel deterioration using ∑(P × S) does not suit daily data, but rather that this method is more suitable for long-term data, such as 10-day or monthly datasets. In a previous publication [6], we calculated weathering intensity using daily data; however, according to the results presented above, the coefficients of correlation between strength retention and weathering intensity were nearly identical whether we used 10-day or monthly data. Therefore, panel deterioration may be estimated without the availability of detailed weather information.

Conclusions

The deterioration of various mat-formed wood-based panels over 7 years of outdoor exposure tests at eight sites in Japan was explored. We measured MOR and IB retentions and found clear regional differences among sites. The panel deterioration rates during 7 years of outdoor exposure were estimated, and distinct differences between the eight sites were found. Finally, the weathering intensity using a modified analysis was calculated, and the correlation coefficient resulting from the relationship between strength retention and the logarithm of weathering intensity showed the highest value when ∑(T × P) was used to indicate weathering intensity.

References

Kojima Y, Norita H, Suzuki S (2009) Evaluating the durability of wood-based panels using thickness swelling results from accelerated aging treatments. For Prod J 59:35–41

Kojima Y, Suzuki S (2011) Evaluating the durability of wood-based panels using internal bond strength results from accelerated aging treatments. J Wood Sci 57(1):7–13

Kojima Y, Suzuki S (2011) Evaluation of wood-based panel durability using bending properties after accelerated aging treatments. J Wood Sci 57(2):126–133

Suzuki S, Watai J (2000) Literature review for durability performance of wood and wood-based material (in Japanese). Bull Shizuoka Univ For 24:63–70

Sekino N, Sato H, Kano K (2009) Nail joint performance of several wood-based panels. Part VII: evaluation of weathering intensity under outdoor exposure (in Japanese). In: Abstract of the 59th annual meeting of the JWRS, 52, Matsumoto, Japan

Kojima Y, Shimoda T, Suzuki S (2011) Evaluation of the weathering intensity of wood-based panels under outdoor exposure. J Wood Sci 57(5):408–414

Japan Meteorological Agency website. http://www.jma.go.jp/jma/index.html. Accessed 10 Feb 2012

Japanese Industrial Standards (1994) JIS standard specification for particleboard, JIS A-5908. Japanese Standards Association, Tokyo

Acknowledgments

This study was supported by a Grant-in aid for Scientific Research (21380108) from Ministry of Education, Culture, Sports, Science and Technology of Japan. The exposure tests were conducted as part of a project organized by the Research Working Group on Wood-based Panels of the Japan Research Society. The authors thank all participants in this project.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Kojima, Y., Shimoda, T. & Suzuki, S. Modified method for evaluating weathering intensity using outdoor exposure tests on wood-based panels. J Wood Sci 58, 525–531 (2012). https://doi.org/10.1007/s10086-012-1287-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10086-012-1287-1