Abstract

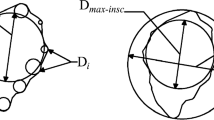

Current spherical particle usage in discrete element modelling (DEM) is not able to accurately reflect the particle shape effect in some specific industrial applications. This study specifically investigated the effect of particle shape in discrete element modelling of a vibratory sieving process, with the focus on comparing results from spherical and non-spherical modelling methods. The particle size distribution of an iron ore material was initially obtained experimentally through vibratory sieving tests. An identical process was replicated in DEM with both spheres and non-spherical particles, and resulting particle size distributions were subsequently compared against the experimental results. A rounded polyhedron shape was utilised to calibrate and generate non-spherical particles based on a 2D particle shape characterisation process. Modelling results suggested that the rounded polyhedron method was able to accurately reflect the particle-sieve contacts without excessive rolling resistance tuning, which was required by the spheres.

Similar content being viewed by others

References

Ai, J., et al.: Assessment of rolling resistance models in discrete element simulations. Powder Technol. 206(3), 269–282 (2011)

Asahina, D., Bolander, J.E.: Voronoi-based discretizations for fracture analysis of particulate materials. Powder Technol. 213(1), 92–99 (2011). doi:10.1016/j.powtec.2011.07.010

Chen, W. et al.: Application of the image processing technique in identifying the particle dispersion from a centrifugal fertilizer spreader. Part. Sci. Technol. 1–9 (2016). doi:10.1080/02726351.2016.1184731

Cleary, P.W., Sinnott, M.D., Morrison, R.D.: Separation performance of double deck banana screens—part 1: flow and separation for different accelerations. Miner. Eng. 22(14), 1218–1229 (2009a)

Cleary, P.W., Sinnott, M.D., Morrison, R.D.: Separation performance of double deck banana screens—part 2: quantitative predictions. Miner. Eng. 22(14), 1230–1244 (2009b)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Delaney, G.W., et al.: Testing the validity of the spherical DEM model in simulating real granular screening processes. Chem. Eng. Sci. 68(1), 215–226 (2012)

Dong, K.J., Yu, A.B., Brake, I.: DEM simulation of particle flow on a multi-deck banana screen. Miner. Eng. 22(11), 910–920 (2009)

Eliáš, J.: Simulation of railway ballast using crushable polyhedral particles. Powder Technol. 264, 458–465 (2014)

Ferellec, J.-F., McDowell, G.R.: A simple method to create complex particle shapes for DEM. Geomech. Geoeng. Int. J. 3(3), 211–216 (2008)

Gonzalez, R.C., Woods, R.E., Eddins, S.L.: Digital Image Processing Using MATLAB. Pearson Education India, London (2004)

Iwashita, K., Oda, M.: Rolling resistance at contacts in simulation of shear band development by DEM. J. Eng. Mech. 124(3), 285–292 (1998)

Pena, A.A., et al.: Influence of particle shape on sheared dense granular media. Granular Matter 9(3), 279–291 (2007)

Potapov, A.: Rocky discrete element modelling software user mannual - version 2.4. Rocky-DEM Inc. Boston, USA (2012)

Price, M., Murariu, V., Morrison, G.: Sphere clump generation and trajectory comparison for real particles. In: Proceedings of Discrete Element Modelling (2007)

Taubin, G.: Geometric signal processing on polygonal meshes. Eurographics Report (2000)

Wensrich, C.M., Katterfeld, A.: Rolling friction as a technique for modelling particle shape in DEM. Powder Technol. 217, 409–417 (2012)

Williams, K.C., et al.: Particle shape characterisation and its application to discrete element modelling. Particuology 12, 80–89 (2014)

Wouterse, A.: On contact numbers in random rod Packings. Granular Matter 11(3), 169–177 (2009)

Zhou, Y.C., et al.: Rolling friction in the dynamic simulation of sandpile formation. Phys. A Stat. Mech. Appl. 269(2), 536–553 (1999)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

This article is part of the Topical Collection on: Understanding granular media - from fundamentals and simulations to industrial application.

Rights and permissions

About this article

Cite this article

Chen, W., Donohue, T., Katterfeld, A. et al. Comparative discrete element modelling of a vibratory sieving process with spherical and rounded polyhedron particles. Granular Matter 19, 81 (2017). https://doi.org/10.1007/s10035-017-0749-y

Received:

Published:

DOI: https://doi.org/10.1007/s10035-017-0749-y