Abstract

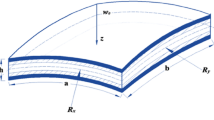

Subject of this analytical investigation is a rotating two-layered hollow cylinder under generalized plane strain subject to an elevated temperature at the inner surface or to internal pressure. It is presupposed that the inner cylindrical layer consists of the heavier material, whereas the outer layer is made of a material with lower density, like for example in a steel/aluminum tube. Criterion for the maximum permissible stress is the yield criterion by von Mises, and the device is optimized with respect to its weight. It is found that plasticization may start at different radii, and the study provides not only a comprehensive overview of the elastic limits of composite tubes of the above type but also a straightforward procedure for determining the optimum composition.

Zusammenfassung

Es werden rotierende zweischichtige Hohlzylinder unter verallgemeinerter ebener Verzerrung und erhöhter Temperatur der Innenwand oder Innendruck auf analytischem Wege untersucht. Es wird vorausgesetzt, daß die innere Schicht aus schwererem und die äuß ere aus leichterem Material besteht, wie etwa in Stahl/Aluminium-Behältern. Die maximal zulässige Spannung wird durch das Fließ kriterium nach von Mises bestimmt, und die Behälter werden bezüglich ihres Gewichts optimiert. Wie gezeigt wird, kann die Fließ grenze an unterschiedlichen Radien erreicht werden, und es werden in dieser Studie sowohl die elastischen Grenzlasten umfassend diskutiert als auch Flussdiagramme zur direkten Bestimmung des jeweiligen optimalen Radienverhältnisses angegeben.

Similar content being viewed by others

Literatur

Yalch JP, McConnelee JE (1967) Plane strain creep and plastic deformation analysis of a composite tube. Nucl Eng Des 5:52–62

Takeuti Y, Tanigawa Y, Noda N, Ochi T (1977) Transient thermal stresses in a bonded composite hollow circular cylinder under symmetrical temperature distribution. Nucl Eng Des 41:335–343

Yang Y-C, Chen C-K (1986) Thermoelastic transient response of an infinitely long annular cylinder composed of two different materials. Int J Eng Sci 24:569–581

Suhir E, Sullivan TM (1990) Analysis of interfacial thermal stresses and adhesive strength of bi-annular cylinders. Int J Solids Struct 26:581–600

Ootao Y, Tanigawa Y, Fukuda T (1991) Axisymmetric transient thermal stress analysis of a multilayered composite hollow cylinder. J Therm Stresses 14:201–213

Tutuncu N, Winckler SJ (1993) Stresses and deformations in thick-walled cylinders subjected to combined loading and a temperature gradient. J Reinf Plast Comp 12:198–209

Tzeng JT, Chien LS (1994) A thermal/mechanical model of axially loaded thick-walled composite cylinders. Compos Eng 4:219–232

Vasilenko AT, Pankratova ND (1995) The thermally stressed state of a thickwalled hollow composite cylinder. J Math Sci 76:2348–2351

Katsuo M, Sawa T, Kawaguchi K, Kawamura H (1996) Axisymmetrical thermal stress analysis of laminated composite finite hollow cylinders restricted at both ends in steady state. DE-Vol. 92, ASME

Kim B-S, Kim T-W, Byun J-H, Lee W-I (1998) Stress analysis of composite/ceramic tube subjected to shrink fit, internal pressure and temperature differences. Key Eng Mat 137:32–39

Lee Z-Y, Chen CK, Hung C-I (2001) Transient thermal stress analysis of multilayered hollow cylinder. Acta Mech 151:75–88

Huang J, Lu Y, Shen C (2003) Thermal elastic-plastic limit analysis and optimal design for composite cylinders of ceramic/metal functionally graded materials. Mater Sci Forum 423–425:681–686

Goshima T, Miyao K (1991) Transient thermal stresses in a composite hollow cylinder subjected to γ-ray heating. Nucl Eng Des 126:413–425

Eraslan AN (2003) Thermally induced deformations of composite tubes subjected to a nonuniform heat source. J Therm Stresses 26:167–193

Eraslan AN, Sener E, Argeso H (2003) Stress distributions in energy generating two-layer tubes subjected to free and radially constrained boundary conditions. Int J Mech Sci 45:469–496

Tutuncu N (1995) Radial stresses in composite thick-walled shafts. J Appl Mech 62:547–549

Tzeng JT (2002) Viscoelastic analysis of composite cylinders subjected to rotation. J Compos Mater 36:229–239

Underwood JH, Carter RH, Troiano E, Parker AP (2010) Mechanics design models for advanced pressure vessels: autofrettage with higher strength steel; steel liner-composite jacket configurations; alternative thermal barrier coatings. Proc. ASME PVP2010–25006

Bakaiyan H, Hosseini H, Ameri E (2009) Analysis of multi-layered filament-wound composite pipes under combined internal pressure and thermomechanical loading with thermal variations. Compos Struct 88:532–541

Ghorbanpour Arani A, Haghparast E, Khoddami Maraghi Z, Amir S (2015) Static stress analysis of carbon nano-tube reinforced composite (CNTRC) cylinder under non-axisymmetric thermo-mechanical loads and uniform electro-magnetic fields. Composites: Part B 68:136–145

Waffenschmidt T, Menzel A (2014) Extremal states of energy of a double-layered thick-walled tube - application to residually stressed arteries. J Mech Behav Biomed Mater 29:635–654

Sharma S, Yadav S (2013) Thermo elastic-plastic analysis of rotating functionally graded stainless steel composite cylinder under internal and external pressure using finite difference method. Adv Mater Sci Eng 2013:11. Article ID 810508

Pardo E, Sanchez Sarmiento G, Laura PAA, Gutierrez RH (1987) Analytical solution for unsteady thermal stresses in an infinite cylinder composed of two materials. J Therm Stresses 10:29–43

Ozturk A, Gulgec M (2013) Determination of onset of yield due to material properties in a heat generating two-layered compound cylinder. Appl Mech Mater 325–326:22–27

Jahed H, Farshi B, Karimi M (2006) Optimum autofrettage and shrink-fit combination in multi-layer cylinders. J Press Vessel Technol 128:196–200

Yuan G, Liu H, Wang Z (2010) Optimum design for shrink-fit multi-layer vessels under ultrahigh pressure using different materials. Chinese J Mech Eng 23:582–589

Arslan E, Mack W, Eraslan AN (2010) The rotating elastic-plastic hollow shaft conveying a hot medium. Forsch Ingenieurwes 74:27–39

Arslan E, Mack W (2015) Shrink fit with solid inclusion and functionally graded hub. Compos Struct 121:217–224

Mack W (1991) Rotating elastic-plastic tube with free ends. Int J Solids Struct 27:1461–1476

Mack W (1992) Entlastung und sekundäres Fließ en in rotierenden elastisch-plastischen Hohlzylindern. Z Angew Math Mech 72:65–68

Eraslan AN, Mack W (2005) A computational procedure for estimating residual stresses and secondary plastic flow limits in nonlinearly strain hardening rotating shafts. Forsch Ingenieurwes 69:65–75

Blanke W (ed) (1989) Thermophysikalische Stoffgrößen. Springer, Berlin

Carslaw HS, Jaeger JC (1959) Conduction of heat in solids. 2nd ed. Clarendon Press, Oxford

Mack W (1993) Thermal assembly of an elastic-plastic hub and a solid shaft. Arch Appl Mech 63:42–50

Chen WF, Han DJ (1988) Plasticity for structural engineers. Springer, New York

Beer FP, Johnston ER Jr, Dewolf JT, Mazurek DF (2009) Mechanics of materials. 5th ed. McGraw Hill, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Apatay, T., Mack, W. On the optimum design of rotating two-layered composite tubes subject to internal heating or pressure. Forsch Ingenieurwes 79, 109–122 (2015). https://doi.org/10.1007/s10010-016-0194-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-016-0194-9