Abstract

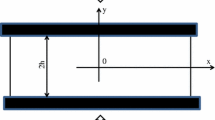

This paper presents a theoretical investigation into heat generation in the continued quasi-static plane strain compression of a thin metal strip between two rigid, parallel perfectly rough dies. The strip material is rigid perfectly plastic. The length of the dies is supposed to be much larger than the current strip thickness. The plastic work rate approaches infinity in the vicinity of perfectly rough friction surfaces. Since the plastic work rate is involved in the heat conduction equation, this significantly adds to the difficulties of solutions of this equation. In particular, commercial finite element packages are not capable of solving such boundary value problems. The present approximate solution is given in Lagrangian coordinates. In this case, the original initial/boundary value problem reduces to the standard second initial/boundary value problem for the nonhomogeneous heat conduction equation. Therefore, the Green’s function is available in the literature. An example is presented to illustrate the general solution.

Similar content being viewed by others

References

Tanner R.I., Johnson W.: Temperature distributions in some fast metal-working operations. Int. J. Mech. Sci. 1, 28–44 (1960)

Hadala B.: Implementation of the heat balance in the finite element solution to the temperature field of the plastically deformed material. Int. J. Therm. Sci. 71, 172–181 (2013)

Abukhshim N.A., Mativenga P.T., Sheikh M.A.: Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining. Int. J. Mach. Tool. Manuf. 46, 782–800 (2006)

Zienkiewicz O.C., Jain P.C., Onate E.: Flow of solids during forming and extrusion. Some aspects of numerical solutions. Int. J. Solids Struct. 14, 15–38 (1978)

Zienkiewicz O.C., Onate E., Heinrich J.C.: A general formulation for coupled thermal flow of metals using finite elements. Int. J. Numer. Meth. Eng. 17, 1497–1514 (1981)

Griffiths B.J.: Mechanisms of white layer generation with reference to machining and deformation processes. Trans. ASME J. Tribol. 109, 525–530 (1987)

Griffiths B.J., Furze D.C.: Tribological advantages of white layers produced by machining. Trans. ASME J. Tribol. 109, 338–342 (1987)

Warren A.W., Guo Y.B.: Numerical investigation on the effects of machining-induced white layer during rolling contact. Tribol. Trans. 48, 436–441 (2005)

Choi Y.: Influence of a white layer on the performance of hard machined surfaces in rolling contact. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 224, 1207–1215 (2010)

Appleby E.J., Lu C.Y., Rao R.S., Devenpeck M.L., Wright P.K., Richmond O.: Strip drawing: a theoretical-experimental comparison. Int. J. Mech. Sci. 26, 351–362 (1984)

Rebelo N., Kobayashi S.: A coupled analysis of viscoplastic deformation and heat transfer-II: applications. Int. J. Mech. Sci. 22, 708–718 (1980)

Chen J.-C., Pan C., Rogue C.M.O.L., Wang H.-P.: A Lagrangian reproducing kernel particle method for metal forming analysis. Comput. Mech. 22, 289–307 (1998)

Wang J.-P.: A new evaluation to friction analysis for the ring test. Int. J. Mach. Tools Manuf. 41, 311–324 (2001)

Chandrasekharan S., Palaniswamy H., Jain N., Ngaile G., Altan T.: Evaluation of stamping lubricants at various temperature levels using the ironing test. Int. J. Mach. Tools Manuf. 45, 379–388 (2005)

Alexandrov S., Richmond O.: Singular plastic flow fields near surfaces of maximum friction stress. Int. J. Non Linear Mech. 36, 1–11 (2001)

Alexandrov S., Mishuris G.: Qualitative behaviour of viscoplastic solutions in the vicinity of maximum-friction surfaces. J. Eng. Math. 65, 143–156 (2009)

Alexandrov S., Jeng Y.-R.: Singular rigid/plastic solutions in anisotropic plasticity under plane strain conditions. Contin. Mech. Thermodyn. 25, 685–689 (2013)

Hill R.: The Mathematical Theory of Plasticity. Clarendon Press, Oxford (1950)

Nepershin R.I.: Non-isothermal plane plastic flow of a thin layer compressed by flat rigid dies. Int. J. Mech. Sci. 39, 899–912 (1997)

Adams M.J., Briscoe B.J., Corfield G.M., Lawrence C.J., Papathanasiou T.D.: An analysis of the plane-strain compression of viscous materials. Trans. ASME J. Appl. Mech. 64, 420–424 (1997)

Polyanin A.D.: Handbook of Linear Partial Differential Equations for Engineers and Scientists. Chapman & Hall/CRC Press, London (2002)

Fries T.-P., Belytschko T.: The extended/generalized finite element method: an overview of the method and its applications. Int. J. Numer. Meth. Eng. 84, 253–304 (2010)

Ng E.-G., Aspinwall D.K., Brazil D., Monaghan J.: Modelling of temperature and forces when orthogonally machining hardened steel. Int. J. Mach. Tools Manuf. 39, 885–903 (1999)

Kim T.-K., Ikeda K.: Flow behavior of the billet surface layer in porthole die extrusion of aluminium. Metall. Mater. Trans. 31, 1635–1643 (2000)

Yiğit K., Tuğrul Ö.: Predictive analytical and thermal modeling of orthogonal cutting process—part I: predictions of tool forces, stresses, and temperature distributions. ASME J. Manuf. Sci. Eng. 128, 435–444 (2006)

Ramesh A., Melkote Shreyes N.: Modeling of white layer formation under thermally dominate condition in orthogonal machining of hardened AISI 52100 steel. Int. J. Mach. Tool. Manuf. 48, 402–414 (2008)

Lalwani D.I., Mehta N.K., Jain P.K.: Extension of Oxley’s predictive machining theory for Johnson and Cook flow stress model. J. Mater. Process. Technol. 209, 5305–5312 (2009)

Akbar F., Mativenga P.T., Sheikh M.A.: An experimental and coupled thermo-mechanical finite element study of heat partition effects in machining. Int. J. Adv. Manuf. Technol. 46, 491–507 (2010)

Chen G., Li J., He Y., Ren C.: A new approach to the determination of plastic flow stress and failure initiation strain for aluminium alloys cutting process. Comput. Mater. Sci. 95, 568–578 (2014)

Agmell M., Ahadi A., Stahl J.-E.: Identification of plastic constants from orthogonal cutting and inverse analysis. Mech. Mater. 77, 43–51 (2014)

Sanabria V., Mueller S., Reimers W.: Microstructure evolution of friction boundary layer during extrusion of AA 6060. Procedia Eng. 81, 586–591 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alexandrov, S., Miszuris, W. Heat generation in plane strain compression of a thin rigid plastic layer. Acta Mech 227, 813–821 (2016). https://doi.org/10.1007/s00707-015-1499-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-015-1499-8