Abstract

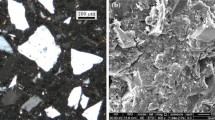

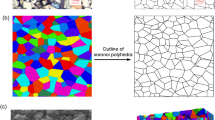

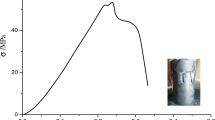

Multiscale continuous lab oratory observation of the progressive failure process has become a powerful means to reveal the complex failure mechanism of rock. Correspondingly, the representative volume element (RVE)-based models, which are capable of micro/meso- to macro-scale simulations, have been proposed, for instance, the rock failure process analysis (RFPA) program. Limited by the computational bottleneck due to the RVE size, multiscale high-resolution modeling of rock failure process can hardly be implemented, especially for three-dimensional (3D) problems. In this paper, the self-developed parallel RFPA3D code is employed to investigate the failure mechanisms and various fracture morphology of laboratory-scale rectangular prism rock specimens under unconfined uniaxial compression. The specimens consist of either heterogeneous rock with low strength or relatively homogeneous rock with high strength. The numerical simulations, such as the macroscopic fracture pattern and stress–strain responses, can reproduce the well-known phenomena of physical experiments. In particular, the 3D multiscale continuum modeling is carried out to gain new insight into the morphologic interpretation of brittle failure mechanisms, which is calibrated and validated by comparing the actual laboratory experiments and field evidence. The advantages of 3D multiscale high-resolution modeling are demonstrated by comparing the failure modes against 2D numerical predictions by other models. The parallel RVE-based modeling tool in this paper can provide an alternative way to investigate the complicated failure mechanisms of rock.

Similar content being viewed by others

Abbreviations

- D :

-

Damage variable

- D ed :

-

Elastic matrix

- E, E 0 :

-

Young’s modulus (elastic modulus) of damaged and undamaged materials

- E ed :

-

Stiffness tensor

- f c :

-

Compressive strength (unconfined, uniaxial)

- f cr :

-

Compressive residual strength

- f t :

-

Tensile strength (uniaxial)

- f tr :

-

Tensile residual strength

- m :

-

Homogeneity index

- n :

-

Unit normal vector

- u :

-

Displacement vector

- \(\varGamma\) :

-

Boundary of the domain

- \(\varGamma_{\text{u}}\) :

-

Displacement boundary

- \(\varGamma_{\sigma }\) :

-

Traction boundary

- \({\varvec{\upvarepsilon}}\) :

-

Strain tensor

- ε 1, ε 2, ε 3 :

-

Maximum, minimum and intermediate principal strain

- ε c0 :

-

Elastic compressive strain limit

- ε t0 :

-

Elastic tensile strain limit

- ε tl :

-

Tensile strain limit

- \(\phi\) :

-

Friction angle

- \(\nu\) :

-

Poisson’s ratio

- ρ :

-

Density

- \({\varvec{\upsigma}}\) :

-

Stress tensor

- σ 1, σ 2, σ 3 :

-

Maximum, minimum, and intermediate principal stress

- \(\varOmega\) :

-

3D domain

References

Bahat D, Rabinovitch A, Frid V (2001) Fracture characterization of chalk in uniaxial and triaxial tests by rock mechanics, fractographic and electromagnetic radiation methods. J Struct 23(10):1531–1547

Bons PD, Elburg MA, Gomez-Rivas E (2012) A review of the formation of tectonic veins and their microstructures. J Struct Geol 43:33–62

Boyd GM (1993) The propagation of fractures in mild steel plates. Engineering 175(16):65–69

Cai M (2008) Influence of intermediate principal stress on rock fracturing and strength near excavation boundaries––insight from numerical modeling. Int J Rock Mech Min Sci 45(5):763–772

Chen YQ, Watanabe K, Kusuda H, Kusaka E, Mabuchi M (2011) Crack growth in Westerly granite during a cyclic loading test. Eng Geol 117(3–4):189–197

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44(7):997–1010

Chow CL, Wang J (1987) An anisotropic theory of elasticity for continuum damage mechanics. Int J Fract 33(1):3–16

Cox SJD, Scholz CH (1988) Rupture initiation in shear fracture of rocks: an experimental study. J Geophys Res 93:3307–3320

Das R, Cleary PW (2010) Effect of rock shapes on brittle fracture using smoothed particle hydrodynamics. Theor Appl Fract Mech 53(1):47–60

De-Carvalho R, Teixeira-Dias F, Varum H (2013) Cyclic behaviour of a lightweight mortar with cork granulate composite. Compos Struct 95:748–755

Fang Z, Harrison JP (2002) Application of a local degradation model to the analysis of brittle fracture of laboratory scale rock specimens under triaxial conditions. Int J Rock Mech Min Sci 39(4):459–476

Feng XT, Pan PZ, Zhou H (2006) Simulation of the rock microfracturing process under uniaxial compression using an elasto-plastic cellular automaton. Int J Rock Mech Min Sci 43(7):1091–1108

Ferrero AM, Migliazza M, Roncella R, Tebaldi G (2008) Analysis of the failure mechanisms of a weak rock through photogrammetrical measurements by 2D and 3D visions. Eng Fract Mech 75(3–4):652–663

Gao FQ, Stead D (2014) The application of a modified Voronoi logic to brittle fracture modelling at the laboratory and field scale. Int J Rock Mech Min Sci 68:1–14

Healy D, Jones RR, Holdsworth RE (2006) Three-dimensional brittle shear fracturing by tensile crack interaction. Nature 439(10):1038

Hull D (1999) Fractography: observing, measuring and interpreting fracture surface topography. Cambridge University Press, Cambridge

Jeffrey WS, Chris NM, Elizabeth SD (2012) Interpretation and significance of reverse chevron-shaped markings on fracture surfaces of API X100 pipeline steels. Mater Sci Eng A 551:140–148

Jia L, Chen M, Zhang W, Xu T, Zhou Y, Hou B, Jin Y (2013) Experimental study and numerical modeling of brittle fracture of carbonate rock under uniaxial compression. Mech Res Commun 50:58–62

Jonathan MR, Frederick MC (2004) Hybrid fracture and the transition from extension fracture to shear fracture. Natute 48(4):63–66

Kahraman S, Alber M (2006) Estimating unconfined compressive strength and elastic modulus of a fault breccia mixture of weak blocks and strong matrix. Int J Rock Mech Min Sci 43(8):1277–1287

Kanit T, Forest S, Galliet I, Mounoury V, Jeulin D (2003) Determination of the size of the representative volume element for random composites: statistical and numerical approach. Int J Solids Struct 40:3647–3679

Kazerani T (2013) A discontinuum-based model to simulate compressive and tensile failure in sedimentary rock. Int J Rock Mech Geotech Eng 5(5):378–388

Lajtai EZ, Carter BJ, Duncan EJS (1994) En echelon crack-arrays in potash salt rock. Rock Mech Rock Eng 27(2):89–111

Lawn B (1993) Fracture of Brittle Solids, 2nd edn. Cambridge University Press, Cambridge

Lemaitre J (1971) Evaluation of dissipation and damage in metals subjected to dynamic loading. In: Proceedings of the international conference on mechanical, vol 1, Kyoto, 15–20 Aug 1971

Li HQ, Wong LNY (2012) Influence of flaw inclination angle and loading condition on crack initiation and propagation. Int J Solids Struct 49(18):2482–2499

Li DY, Li CC, Li XB (2011) Influence of sample height-to-width ratios on failure mode for rectangular prism samples of hard rock loaded in uniaxial compression. Rock Mech Rock Eng 44(3):253–267

Li LC, Tang CA, Wang SY, Yu J (2013) A coupled thermo–hydrologic–mechanical damage model and associated application in a stability analysis on a rock pillar. Tunn Undergr Space Tech 34:38–53

Liang ZZ, Xing H, Wang SY, Williams DJ, Tang CA (2012) A three-dimensional numerical investigation of the fracture of rock specimens containing a pre-existing surface flaw. Comput Geotech 45:19–33

Lin ZH, Xiang W, Zhang YM (2010) Experimental research on influences of physical indices and microstructure parameters on strength properties of red stone from western Hunan. Chin J Rock Mech Eng 29(1):124–134

Liu HY, Kou SQ, Lindqvista PA, Tang CA (2004) Numerical studies on the failure process and associated microseismicity in rock under triaxial compression. Tectonophysics 384:149–174

Lu YL, Elsworth D, Wang LG (2013) Microcrack-based coupled damage and flow modeling of fracturing evolution in permeable brittle rocks. Comput Geotech 49:226–244

Ma GW, Wang XJ, Ren F (2011) Numerical simulation of compressive failure of heterogeneous rock-like materials using SPH method. Int J Rock Mech Min Sci 48(3):353–363

Miao JL, He MC, Li DJ, Zeng FJ, Zhang X (2009) Acoustic emission characteristics of granite under strain rock burst test and its micro-fracture mechanism. Chin J Rock Mech Eng 28(8):1593–1603

Molladavoodi H, Mortazavi A (2011) A damage-based numerical analysis of brittle rocks failure mechanism. Finite Elem Anal Des 47(9):991–1003

Nasseri MHB, Goodfellow SD, Lombos L, Young RP (2014) 3-D transport and acoustic properties of Fontainebleau sandstone during true-triaxial deformation experiments. Int J Rock Mech Min Sci 69:1–18

Pan PZ, Feng XT, Hudson JA (2009) Study of failure and scale effects in rocks under uniaxial compression using 3D cellular automata. Int J Rock Mech Min Sci 46(4):674–685

Park CH, Bobet A (2010) Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression. Eng Fract Mech 77(14):2727–2748

Petit JP, Barquins M (1988) Can natural faults propagate under mode II conditions? Tectonics 7:1243–1256

Rocha-Rangel E (2011) Fracture toughness determinations by means of indentation fracture. In: Cuppoletti J (ed) Nanocomposites with unique properties and applications in medicine and industry. Intech, pp 21–37

Senent S, Jimenez R, Reyes A (2013) Numerical simulation of the influence of small-scale defects on the true-triaxial strength of rock samples. Comput Geotech 53:142–156

Shen WQ, Shao JF, Kondo D, Gatmiric B (2012) A micro-macro model for clayey rocks with a plastic compressible porous matrix. Int J Plast 36:64–85

Shimizu H, Koyama T, Ishida T, Chijimatsu M, Fujita T, Nakama S (2010) Distinct element analysis for Class II behavior of rocks under uniaxial compression. Int J Rock Mech Min Sci 47(2):323–333

Smolin AY, Roman NV, Konovalenko IS, Anikeeva GM, Buyakova SP, Psakhie SG (2014) 3D simulation of dependence of mechanical properties of porous ceramics on porosity. Eng Fract Mech. doi:10.1016/j.engfracmech.2014.04.001

Tan X, Konietzky H, Frühwirt T (2014) Laboratory observation and numerical simulation of permeability evolution during progressive failure of brittle rocks. Int J Rock Mech Min Sci 68:167–176

Tang CA (1997) Numerical simulation of progressive rock failure and associated seismicity. Int J Rock Mech Min Sci 34(2):249–262

Toribio J (2004) Microstructure-based modelling of fracture in progressively drawn pearlitic steels. Eng Fract Mech 71(4–6):769–777

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Xiao QZ, Karihaloo BL (2006) Asymptotic fields at frictionless and frictional cohesive crack tips in quasi-brittle materials. J Mech Mater Struct 1:881–910

Xie Q, Jiang CX, Ling JM (1997) Meso-mechanics of rock-experiment and analysis. Southwest Jiaotong University Press, Chengdu

Xu XH, Ma SP, Xia MF, Ke FJ, Bai YL (2005) Synchronous multi-scale observations on rock damage and rupture. Theor Appl Fract Mech 44(2):146–156

Yang SQ, Jiang YZ, Xu WY, Chen XQ (2008) Experimental investigation on strength and failure behaviour of pre-cracked marble under conventional triaxial compression. Int J Solids Struct 45(17):4796–4819

Zhang ZN, Ge XR (2007) Multiscale shear fracture of heterogeneous material using the virtual internal bond. Theor Appl Fract Mech 47(3):185–191

Zhang W, Chen JP, Chen HE, Xu DZ, Li Y (2013) Determination of RVE with consideration of the spatial effect. Int J Rock Mech Min Sci 61:154–160

Zhou XP, Cheng H, Feng YF (2013) An experimental study of crack coalescence behaviour in rock-like materials containing multiple flaws under uniaxial compression. Rock Mech Rock Eng. doi:10.1007/s00603-013-0511-7

Acknowledgments

This work is supported by Grants from the 973 program (Grant No. 2014CB047100), the National Science Foundation of China (Grant No. 51309261, 41030747, 51108472, 51274053), the Natural Science Foundation of Guangdong Province China (Grant No. S2013040016764, S2011040005172, S2012010010446), the Fundamental Research Funds for the Central Universities (Grant No. 14lgpy11) and State Key Laboratory for Geomechanics and Deep Underground Engineering, China University of Mining & Technology (Grant No. SKLGDUEK1423). We would like to express our sincerest gratitude to the anonymous reviewers for their valuable modification suggestions on the significant improvement of this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, G., Liang, ZZ. & Tang, CA. Morphologic Interpretation of Rock Failure Mechanisms Under Uniaxial Compression Based on 3D Multiscale High-resolution Numerical Modeling. Rock Mech Rock Eng 48, 2235–2262 (2015). https://doi.org/10.1007/s00603-014-0698-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-014-0698-2