Abstract

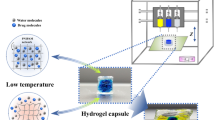

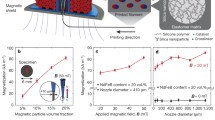

Functional and intelligent soft materials are useful for controlled release of medicines and other molecules. Poly(N-isopropylacrylamide) (PNIPAm) gels are well known as thermo-responsive gels with large discontinuous volume change which is commonly called as the volume phase transition. PNIPAm gels are expected to be applied to controlled-releasable material for drug delivery systems. Furthermore, we can fabricate arbitrary shapes made of gels freely by using 3D hydrogel printing techniques. Here we report that the effect of capsule shapes on behaviors of the PNIPAm objects under water flow with Reynolds number 102. In addition, we compared the behaviors of 3D-printed PNIPAm gel objects with 3D-printed polylactic acid (PLA) objects. The velocity at the first period of 2 or 3 s from the beginning of movement is slower than that of second period in the case of PNIPAm objects with ellipsoidal and bullet shapes. In other words, the capsules are accelerated after the period of 2 or 3 s. For the bullet shape objects, the velocity of the PNIPAm gel is approximately three times faster than that of PLA. It is considered that the cause of the difference between the velocities of PLA and PNIPAm gel is the difference of their frictions. The hydrogels possess commonly low friction properties. Finally, it is demonstrated that the 3D-printed PNIPAm capsules can release the solution inside the capsules by shrinking the PNIPAm gels, caused by volume phase transition.

Similar content being viewed by others

References

Arai KD, Saito A, Ito K, Uematsu Y, Ueno T, Fujii Y, Nishio I (2013) Isobars, the coexistence curve, and the critical exponent β of N-isopropylacrylamide gels obtained using a simple experimental method. Phys Rev E 87(2):022603

Atkins P, De Paula J (2006) Atkins’s physical chemistry, 8th edn. W. H. Freeman and Company, New York

Bhattarai N, Gunn J, Zhang M (2010) Chitosan-based hydrogels for controlled, localized drug delivery. Adv Drug Deliv Rev 62:83–99

Chung BG, Lee K-H, Khademhosseini A, Lee S-H (2012) Microfluidic fabrication of microengineered hydrogels and their application in tissue engineering. Lab Chip 12:45–59

Galler KM, Hartgerink JD, Cavender AC, Schmalz G, D’Souza RN (2012) Customized self-assembling peptide hydrogel for dental pulp tissue engineering. Tissue Eng Part A 18(1–2):176–184

Goy CB, Chaile RE, Madrid RE (2019) Microfluidics and hydrogel: a powerful combination. React Funct Polym 145:104314

Gupta MK, Meng F, Johnson BN, Kong YL, Tian L, Yeh YW, Masters N, Singamaneni S, McAlpine MC (2015) 3D printed programmable release capsules. Nano Lett 15(8):5321–5329

Han D, Lu Z, Chester SA, Lee H (2018) Micro 3D printing of a temperature-responsive hydrogel using projection micro-stereolithography. Sci Rep 8:1963

Hirokawa Y, Tanaka T (1984) Volume phase transition in a nonionic gel. J Chem Phys 81(12):6379

Huang GY, Zhou LH, Zhang QC, Chen YM, Sun W, Xu F, Lu TJ (2011) Microfluidic hydrogels for tissue engineering. Biofabrication 3:012001

Javanbakht S, Shaabani A (2019) Encapsulation of graphene quantum dot-crosslinked chitosan by carboxymethylcellulose hydrogel beads as a pH-responsive bio-nanocomposite for the oral delivery agent. Int J Biol Macromol 123:389–397

Li J, Mooney DJ (2016) Designing hydrogels for controlled drug delivery. Nat Rev Mater 1(12):16071

Lide (ed) (2006) CRC handbook of chemistry and physics, 86th edn. CRC Press, Boca Raton

Martinez PR, Goyanes A, Basita AW, Gaisford S (2017) Fabrication of drug-loaded hydrogels with stereolithographic 3D printing. Int J Pharm 532(1):313–317

Matsuda T, Kawakami R, Namba R, Nakajima T, Gong JP (2019) Mechanoresponsive self-growing hydrogels inspired by muscle training. Science 363(6426):504–508

Muroi H, Hidema R, Gong J, Furukawa H (2013) Development of optical 3D gel printer for fabricating free-form soft & wet industrial materials and evaluation of printed double-network gels. J Solid Mech Mater Eng 7(2):163–168

Nguyen NT, Wereley ST (2006) Fundamentals and applications of microfluidics, 2nd edn. Artech House, Norwood

Nie J, Gao Q, Wang Y, Zeng J, Zhao H, Sun Y, Shen J, Ramezani H, Fu Z, Liu Z, Xiang M, Fu J, Zhao P, Chen W, He Y (2018) Vessel-on-a-chip with hydrogel-based microfluidics. Small 14(45):1802368

Osada Y, Matsuda A (1995) Shape memory in hydrogels. Nature 376:219

Ota T, Yoshida K, Tase T, Sato K, Tanaka M, Saito A, Takamatsu K, Kawakami M, Furukawa H (2018) Influence of 3D-printing conditions on physical properties of hydrogel objects. Mech Eng J 5(1):17–00538

Ota T, Saito A, Tase T, Sato K, Tanaka M, Yoshida K, Takamatsu K, Kawakami M, Furukawa H (2019) 3D printing of tough gels having tunable elastic modulus from the same pre-gel solution. Macromol Chem Phys 220(12):1800498

Papathanasiou KE, Turhanen P, Brückner SI, Brunner E, Demadis KD (2017) Smart, programmable and responsive injectable hydrogels for controlled release of cargo osteoporosis drugs. Sci Rep 7:4743

Saito A, Kimura J, Fujii Y, Nishio I (2013) Volume phase transition of N-isopropylacrylamide gels crosslinked by a crosslinker with six hands. Phys Rev E 88(6):062601

Shiblee MDNI, Ahmed K, Khosla A, Kawakami M, Furukawa H (2018) 3D printing of shape memory hydrogels with tunable mechanical properties. Soft Matter 14:7809–7817

Shiblee MDNI, Ahmed K, Kawakami M, Furukawa H (2019) 4D printing of shape-memory hydrogels for soft-robotic functions. Adv Mater Technol 4(8):1900071

Tanaka T (1978) Collapse of gels and the critical endpoint. Phys Rev Lett 40(12):820

Tanaka T, Fillmore D, Sun S-T, Nishio I, Swislow G, Shah A (1980) Phys Rev Lett 45(20):1636

Tanaka T, Nishio I, Sun S-T, Ueno-Nishio S (1982) Collapse of gels in an electric field. Science 218(4571):467–469

Yoshida R, Takahashi T, Yamaguchi T, Ichijo H (1996) Self-oscillating gel. J Am Chem Soc 118(21):5134–5135

Acknowledgements

This work was supported in part by JSPS KAKENHI Grant Numbers JP17H01224, JP18H05471, JP19H01122, Japan Science and Technology Agency (JST)-Center Of Innovation (COI) Grant Number JPMJCE1314, JST-Program on Open Innovation Platform with Enterprises Research Institute and Academia (OPERA) Grant Number JPMJOP1844, JST-OPERA Program Grant Number JPMJOP1614, and the Cabinet Office (CAO), Cross-ministerial Strategic Innovation Promotion Program (SIP), “An intelligent knowledge processing infrastructure, integrating physical and virtual domains” (funding agency: NEDO).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yoshida, K., Nezu, K., Khosla, A. et al. Behaviors of 3D-printed objects made of thermo-responsive hydrogels: motion in flow and molecule release ability. Microsyst Technol 28, 417–422 (2022). https://doi.org/10.1007/s00542-020-04904-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-04904-8