Abstract

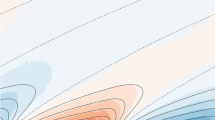

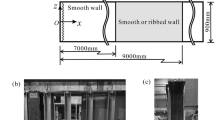

The influences of diverging angle, excitation frequency and volume change rate of the pump chamber on the valveless piezoelectric micropump with planar diffuser/nozzle elements are studied. The diverging angle ranges from 5° to 60°, the amplitude of the membrane ranges from 0.5 to 80 μm, the excitation frequency ranges from 10 to 5000 Hz. The deformation model of the membrane is verified by experiments. The performance of the micropump is predicted by numerical simulation. The simulation results agree with the experiment results very well. Statistical analysis of the location and duration of vortexes in internal flow field is used to reveal the relationships among efficiency, diverging angle, frequency and chamber volume change rate. As the frequency ranges from 100 to 1000 Hz, the efficiency increases sharply because the tube is partially blocked by vortexes at suction stage. The vortexes in the diffuser/nozzle elements is brought by the great adverse pressure gradient at the high frequency.

Similar content being viewed by others

Abbreviations

- a :

-

The radius of the central part

- b :

-

The outer radius of the outer region

- f :

-

Excitation frequency

- H :

-

The deep of the diffuser/nozzle element

- L :

-

The length of the diffuser/nozzle element

- P in :

-

The pressure at the inlet

- P out :

-

The pressure at the outlet

- q(t):

-

Transient flow rare

- R :

-

The rounding at the throat

- T :

-

Period

- \(\bar{v}\) :

-

The average velocity at the throat

- V :

-

The volume change of the pump chamber

- w 1 :

-

The deflection of the central part

- w 2 :

-

The deflection of the outer region

- w max :

-

The amplitude of the membrane

- W :

-

The width of the throat

- θ :

-

Diverging angle

- ρ :

-

Density of the medium

- η :

-

Efficiency of the piezoelectric micropump

References

Ahn CH, Allen MG (1995) Fluid micropumps based on rotary magnetic actuators. In: Proceedings of IEEE micro electro mechanical systems (MEMS), Amsterdam, Netherlands, pp 408–412

Andersson H, Wijngaart W (2001) A valve-less diffuser micropump for microfluidic analytical systems. Sens Actuators B 72:259–265

Aravind T, Kumar SP (2013) A novel thermopneumatic based micropump and microvalve using phase change liquid. 2013 International conference on smart structures and systems (JCSSS-20 13), Chennai, India, pp 66–69

Azarbadegan A, Eames I (2011) Computational study of parallel valveless micropumps. Sens Actuators B 158:432–440

Bodén R (2006) A polymeric paraffin actuated high-pressure micropump. Sens Actuators A 127:88–93

Bu M, Tracy M, Graham E (2003) Design and theoretical evaluation of a novel microfluidic device to be used for PCR. J Micromech Microeng 13:S125–S130

Cheng P, Wu HY (2007) Phase-change heat transfer in microsystems. J Heat Transf 129:101–107

Dewa AS, Deng K, Ritter DC, Bonham C (1997) Development of LIGA-fabricated, self-priming, inline gear pumps. Transducers’97, Chicago, pp 757–760

Gravesen P, Branebjerg J (1993) Microfluidics: a review. J Micromech Microeng 3:168–182

Guan YF, Zhang GX, Ren JC (2009) Fabrication and experiment studies of the piezoelectric micropump with saw-tooth microchannel. In: Proceedings-2009 IEEE international conference on intelligent computing and intelligent systems 2, pp 733–737

He XH, Cai SC (2014) Transient characteristics of flat-wall diffuser/nozzle elements of valveless piezoelectric micropumps. J Xi’An Jiaotong Univ 48(5):89–95

Hsu YC, Le NB (2009) Equivalent electrical network for performance characterization of piezoelectric peristaltic micropump. Microfluid Nanofluid 7:237–248

Izzo I, Accoto D, Menciassi A, Schmitt L, Dario P (2007) Modeling and experimental validation of a piezoelectric micropump with novel no-moving-part valves. Sens Actuators A 133:128–140

Jiang XN, Zhou ZY (1998) Micronozzle/diffuser flow and its application in micro valveless pumps. Sens Actuators A 70:81–87

Kuo CT, Liu CH (2009) A bubble-free AC electrokinetic micropump using the asymmetric capacitance-modulated microelectrode array for microfluidic flow control. J Microelectromech Syst 18(1):38–51

Lu F, Xie LY (2005) Investigation and application on micropump. Fluid Mach 33(6):29–34

Menter FR, Kuntz M, Langtry R (2003) Ten years of industrial experience with the SST turbulence model. In: Proceedings of the 4th international symposium on turbulence, heat and mass transfer, Antalya, Turkey, 12–17 October, 2003, pp 625–663

Nguyen NT, Huang X, Chuan TK (2002) MEMS-micropumps: a review. Trans ASME J Fluids Eng 124:384–392

Olsson A, Stemme G (2000) Numerical and experimental studies of flat-walled diffuser elements for valve-less micropumps. Sens Actuators 84:165–175

Olsson A, Stemme G, Stemme E (1995) A valve-less planar fluid pump with two pump chambers. Sens Actuators A 47:549–556

Peng XF, Peterson GP, Wang BX (1994) Frictional flow characteristics of water flowing through rectangular microchannels. Exp Heat Transf 7:249–264

Singhal V, Garimella SV (2004) Low Reynolds number flow through nozzle-diffuser elements in valveless micropumps. Sens Actuators A 113:226–235

Singhal V, Garimella SV, Raman A (2004) Microscale pumping technologies for microchannel cooling systems. Appl Mech Rev 57(3):191–221

Yang S, Yuan SQ, Cai SC, Wei DD, He XH (2014) A valveless piezoelectric micropump based on Coanda effect. Trans Chin Soc Agric Mach 45:343–348

Spencer WJ (1978) An electronically controlled piezo-electric insulin pump and valves. IEEE Trans Sonics Ultrason 25(3):153–156

Stemme E, Stemme G (1993) A valveless diffuser/nozzle fluid pump. Sens Actuators A 39:159–167

Su YF, Chen WY (2006) Electro-magnetically actuated valveless micropump with two flexible diaphragms. Int J Adv Manuf Technol 30:215–220

Tanaka S, Tsukamoto H (2008) Development of diffuser/nozzle based valveless micropump. J Fluid Sci Technol 3(8):999–1007

Wang CT, Chen YM (2014) Tesla valves in micromixers. Int J Chem React Eng 12(1):397–403

Wang YC, Hsu JC (2009) Loss characteristics and flow rectification property of diffuser valves for micropump applications. Int J Heat Mass Transf 52:328–336

Wang XY, Cheng C (2009) Electroosmotic pumps and their applications in microfluidic systems. Microfluid Nanofluid 6:145–162

Yuan SQ, Yang S (2015) Design and experimental study of a novel three-way diffuser/nozzle elements employed in valveless piezoelectric micropumps. J Braz Soc Mech Sci Eng 37:221–230

Zhang T, Wang QM (2005) Valveless piezoelectric micropump for fuel delivery in direct methanol fuel cell (DMFC) devices. J Power Sources 140:72–80

Acknowledgments

This work was supported by the project of the National Natural Science Foundation of China [Grant Number: 51276082]. Departments of Education and Finance, Jiangsu Province of P.R. China (A Project Funded by the Priority Academic Program Development of Jiangsu Higher Education institutions, PAPD) [Grant Number: SUZHENGBANFA (2014) No. 37].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, X., Zhu, J., Zhang, X. et al. The analysis of internal transient flow and the performance of valveless piezoelectric micropumps with planar diffuser/nozzles elements. Microsyst Technol 23, 23–37 (2017). https://doi.org/10.1007/s00542-015-2695-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-015-2695-0