Abstract

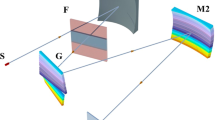

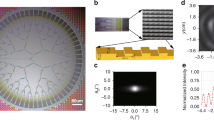

In the near infrared (NIR) micro spectrometer system, a scanning grating is the most critical component which makes spectrometer operate with one single photodiode instead of expensive photodiode array. However, most scanning gratings have low diffraction efficiency and are not integrated with sensor to monitor the state of the scanning grating. To solve these problems, a novel scanning grating for NIR micro spectrometers is presented and designed. The scanning grating consists of grating, electromagnetic actuator and angle sensor, which are integrated in a chip. Based on a tilted (111) silicon substrate, a blazed grating structure can be obtained by wet anisotropic etching the substrate, and the desired blaze angle can be easily realized by choosing the appropriate tilt angle of device silicon. Simulation results show that the efficiency of the grating with grating constant of 4 μm is more than 50 % over the wavelength range from 800 to 1,800 nm and the maximum efficiency reaches to 90 %. In order to satisfy the requirement of the operating wavelength range, an electromagnetic actuator is designed to drive the millimeter-sized (6.96 × 6.36 mm2) grating plate to achieve large scanning angle, and theoretical analysis shows that the maximum optical deflection angle is ± 10.8° at frequency of 600.5 Hz. An electromagnetic angle sensor is designed to detect the state of the scanning grating and supply the feedback signal for close loop control. Theoretical results show that the voltage output of angle sensor is 1.3226 × 10−4 V/rad/s with magnetic flux density being 400mT.

Similar content being viewed by others

References

Asada N, Matsuki H, Minami K, Esashi M (1994) Silicon micromachined two-dimensional galvano optical scanner magnetics. IEEE Transact 30:4647–4649

Du Y, Zhou G, Cheo KK, Zhang Q, Feng H, Yang B, Chau FS (2009) High speed laser scanning using MEMS driven in-plane vibratory grating: design, modeling and fabrication. Sens Actuators A Phys 156:134–144

Du Y, Zhou G, Cheo KKL, Zhang Q, Feng H, Chau FS (2010) A high-speed MEMS grating laser scanner with a backside thinned grating platform fabricated using a single mask delay etching technique. J Micromech Microeng 20:115028

Ferreira L, Moehlecke S (1999) A silicon micromechanical galvanometric scanner. Sens Actuators A Phys 73:252–260

Fujii Y, K-i Aoyama, J-i Minowa (1980) Optical demultiplexer using a silicon echelette grating. IEEE J Quantum Electron 16:165–169

Goodman JW (2005) Introduction to Fourier optics. Roberts and Company Publishers

Harada T, Sakuma H, Fuse M (1998) Fabrication of blazed gratings and grisms utilizing anisotropic etching of silicon. In: SPIE’s International Symposium on Optical Science, Engineering, and Instrumentation, 1998. International Society for Optics and Photonics, pp 11–16

Hutley MC (1982) Diffraction gratings. Academic Press, London

Lenzhofer M, Tortschanoff A, Frank A, Sandner T, Schenk H, Kraft M, Kenda A (2009) Position encoding and closed loop control of MOEMS translatory actuators. In: SPIE Europe Microtechnologies for the New Millennium, 2009. International Society for Optics and Photonics, p 736212

Miller RA, Tai Y-C (1997) Micromachined electromagnetic scanning mirrors. Opt Eng 36:1399–1407

Miyajima H, Asaoka N, Arima M, Minamoto Y, Murakami K, Tokuda K, Matsumoto K (2001) A durable, shock-resistant electromagnetic optical scanner with polyimide-based hinges. J Microelectromech Syst 10:418–424

Miyajima H et al (2003) A MEMS electromagnetic optical scanner for a commercial confocal laser scanning microscope. J Microelectromech Syst 12:243–251

Philippe P, Valette S, Mendez OM, Maystre D (1985) Wavelength demultiplexer: using echelette gratings on silicon substrate. Appl Opt 24:1006–1011

Qiao D-Y, Kang B-P, Liu Y-B, Yang X, Shi L-F (2013) A resonance scanning grating based on SOI for microspectrometer application. Laser Phys 23:035601

Tortschanoff A et al (2010) Position encoding and phase control of resonant MOEMS mirrors. Sens Actuators A Phys 162:235–240

Voronov DL et al (2010) High-efficiency 5000 lines/mm multilayer-coated blazed grating for extreme ultraviolet wavelengths. Opt Lett 35:2615–2617

Wong CW, Jeon Y, Barbastathis G, Kim S-G (2004) Analog piezoelectric-driven tunable gratings with nanometer resolution. J Microelectromech Syst 13:998–1005

Zimmer F, Grueger H, Heberer A, Sandner T, Wolter A, Schenk H (2005) Scanning micro-mirrors: from bar-code scanning to spectroscopy. In: Optics and Photonics 2005. International Society for Optics and Photonics, pp 84–94

Acknowledgments

This work was supported by the National Natural Science Foundation of China (NSFC) (NO. 61327002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, Q., Wen, Z. & Huang, J. A high-performance scanning grating based on tilted (111) silicon wafer for near infrared micro spectrometer application. Microsyst Technol 21, 1749–1755 (2015). https://doi.org/10.1007/s00542-014-2354-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-014-2354-x