Abstract

Background

Ultrasonic energy devices are essential for effective hemostasis during endoscopic surgery. Ultrasonic tissue transection occurs as a result of mechanical friction between the oscillating blade and the tissue. We hypothesized that blade surface structures and characteristics would affect tissue transection and sealing. The aim of this study was to clarify the efficacy of blade surface structures and characteristics in vessel sealing with an ultrasonic vibration.

Methods

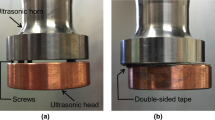

We developed an ultrasonic energy device with 50-kHz vibration frequency and 50 μm amplitude. We manufactured four types of blade surface of the ultrasonic device using microprocessing technology: (1) a non-coated blade without microgrooves, (2) a non-coated blade with microgrooves, (3) a water-repellent-coated blade without microgrooves, and (4) a water-repellent-coated blade with microgrooves. We compared the performance of the four devices and a commercially available ultrasonic device with a non-coated blade without microgrooves in an ex vivo vessel-sealing experiment. We sealed porcine carotid arteries (3–5 mm diameter) using each device 20 times.

Results

The cutting time of the water-repellent-coated blade with microgrooves was the shortest (11.0 ± 3.4 s); however, it did not differ significantly from that of the commercial ultrasonic device (12.9 ± 2.9 s, p = 0.73). The burst pressure of the water-repellent-coated blade without microgrooves (1456 ± 425 mmHg) was significantly higher than that of the commercial ultrasonic device (966 ± 559 mmHg, p = 0.04). The sealing failure rate of the water-repellent blade with microgrooves was the lowest of all devices (0 %). Instrumental sticking of tissue decreased in the water-repellent devices. The sealing width was not significantly different.

Conclusion

The surface-processing of microgrooves and water-repellent coatings will improve the potential of ultrasonic devices with a fast transection and a high sealing reliability.

Similar content being viewed by others

References

Ceppa DP, Kosinski AS, Berry MF, Tong BC, Harpole DH, Mitchell JD, D’Amico TA, Onaitis MW (2012) Thoracoscopic lobectomy has increasing benefit in patients with poor pulmonary function: a Society of Thoracic Surgeons Database analysis. Ann Surg 256:487–493

Committee for Scientific Affairs TJATS, Masuda M, Kuwano H, Okumura M, Arai H, Endo S, Doki Y, Kobayashi J, Motomura N, Nishida H, Motomura N, Saiki Y, Tanaka F, Tanemoto K, Toh Y, Yokomise H (2015) Thoracic and cardiovascular surgery in Japan during 2013: annual report by The Japanese Association for Thoracic Surgery. Gen Thorac Cardiovasc Surg 63:670–701

Milsom JW, Trencheva K, Sonoda T, Nandakumar G, Shukla PJ, Lee S (2015) A prospective trial evaluating the clinical performance of a novel surgical energy device in laparoscopic colon surgery. Surg Endosc 29:1161–1166

Berber E, Akyuz M, Aucejo F, Aliyev S, Aksoy E, Birsen O, Taskin E (2014) Initial experience with a new articulating energy device for laparoscopic liver resection. Surg Endosc 28:974–978

Schuchert MJ, Abbas G, Pettiford BL, Luketich JD, Landreneau RJ (2010) Preliminary results of anatomic lung resection using energy-based tissue and vessel coagulative fusion technology. J Thorac Cardiovasc Surg 140:1168–1173

Sakuragi T, Okazaki Y, Mitsuoka M, Yamasaki F, Masuda M, Mori D, Satoh T, Itoh T (2008) The utility of a reusable bipolar sealing instrument, BiClamp((R)), for pulmonary resection. Eur J Cardiothorac Surg 34:505–509

Tanaka R, Gitelis M, Meiselman D, Abar B, Zapf M, Carbray J, Vigneswaran Y, Zhao JC, Ujiki M (2015) Evaluation of vessel sealing performance among ultrasonic devices in a Porcine model. Surg Innov 22:338–343

Seehofer D, Mogl M, Boas-Knoop S, Unger J, Schirmeier A, Chopra S, Eurich D (2012) Safety and efficacy of new integrated bipolar and ultrasonic scissors compared to conventional laparoscopic 5-mm sealing and cutting instruments. Surg Endosc 26:2541–2549

Newcomb WL, Hope WW, Schmelzer TM, Heath JJ, Norton HJ, Lincourt AE, Heniford BT, Iannitti DA (2009) Comparison of blood vessel sealing among new electrosurgical and ultrasonic devices. Surg Endosc 23:90–96

Hruby GW, Marruffo FC, Durak E, Collins SM, Pierorazio P, Humphrey PA, Mansukhani MM, Landman J (2007) Evaluation of surgical energy devices for vessel sealing and peripheral energy spread in a porcine model. J Urol 178:2689–2693

Chen C, Kallakuri S, Vedpathak A, Chimakurthy C, Cavanaugh JM, Clymer JW, Malaviya P (2012) The effects of ultrasonic and electrosurgery devices on nerve physiology. Br J Neurosurg 26:856–863

Foschi D, Cellerino P, Corsi F, Taidelli T, Morandi E, Rizzi A, Trabucchi E (2002) The mechanisms of blood vessel closure in humans by the application of ultrasonic energy. Surg Endosc 16:814–819

Richter S, Kollmar O, Schilling MK, Pistorius GA, Menger MD (2006) Efficacy and quality of vessel sealing: comparison of a reusable with a disposable device and effects of clamp surface geometry and structure. Surg Endosc 20:890–894

Lyons SD, Law KS (2013) Laparoscopic vessel sealing technologies. J Minim Invasive Gynecol 20:301–307

Shimada J (2014) Rough surface blade. Japan Patent Number 2014/195778 (pending)

Rothmund R, Kraemer B, Neis F, Brucker S, Wallwiener M, Reda A, Hausch A, Scharpf M, Szyrach MN (2012) Efficacy and safety of the novel electrosurgical vessel sealing and cutting instrument BiCision(R). Surg Endosc 26:3334–3343

Roy RK, Lee KR (2007) Biomedical applications of diamond-like carbon coatings: a review. J Biomed Mater Res B Appl Biomater 83:72–84

Phillips CK, Hruby GW, Mirabile G, Motamedinia P, Durak E, Lehman DS, Hong PW, Landman J (2008) The effect of intraluminal content on the bursting strength of vessels ligated with the harmonic ACE and LigaSure V. J Endourol 22:1383–1387

Berdah SV, Hoff C, Poornoroozy PH, Razek P, Van Nieuwenhove Y (2012) Postoperative efficacy and safety of vessel sealing: an experimental study on carotid arteries of the pig. Surg Endosc 26:2388–2393

Acknowledgments

This study was financially supported by a Grant for Support of Studies and Developments by Cooperation of Industry and Academia, Kyoto Industrial Support Organization 21 Foundation, 2014–2015, Kinugawa Factory, Kyoto, Japan, Kyoshin Electoric, Kyoto, Japan, Mostec, Kyoto, Japan, and Reverse Fit Design, Kyoto, Japan. The authors would like to thank Masayoshi Inoue (Division of Thoracic Surgery, Department of Surgery, Graduate School of Medical Science, Kyoto Prefectural University of Medicine, Kyoto, Japan) for his help in data interpretation and manuscript revision.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Disclosures

Junichi Shimada has a patent pending on “Rough surface blade” (Japan Patent Number 2014/195778). Satoru Okada, Kazuhiro Ito have no conflicts of interest or financial ties to disclose. Tatsuo Ishii is employed at Kinugawa Factory, Japan. Koichiro Oshiumi is employed at Reverse Fit Design, Japan.

Rights and permissions

About this article

Cite this article

Okada, S., Shimada, J., Ito, K. et al. Surface-processing technology of a microgrooving and water-repellent coating improves the fusion potential of an ultrasonic energy device. Surg Endosc 31, 887–893 (2017). https://doi.org/10.1007/s00464-016-5048-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00464-016-5048-x