Abstract

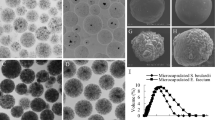

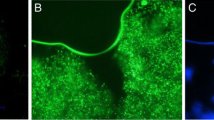

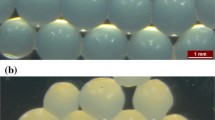

Gamma-aminobutyric acid (GABA) production by free and Ca-alginate encapsulated cells of Enterococcus faecium CFR 3003 was investigated. Mass transfer rates characterizing the GABA production process using encapsulated cells were investigated. Experiments were performed to investigate external film and internal pore diffusion mass transfer rates. The Damkohler and Thiele analysis provides a good description of external film and internal pore diffusion resistances, respectively. The experiments revealed that the external film effects could be neglected but the process is affected to the greater extent by internal mass transfer effects and was found to be the principal rate-controlling step. Protective effect of encapsulation on cell survivability was tested under digestive environment, when challenged to salivary α-amylase, simulated gastric fluid and intestinal fluid. Viability of encapsulated cells was significantly higher under simulated gastro-intestinal conditions and could produce higher GABA than those observed with free cells. The results indicate that the Ca-alginate encapsulated probiotics could effectively be delivered to the colonic site for effective inhibitory action.

Similar content being viewed by others

References

Krnjevic K (1974) Chemical nature of synaptic transmission in vertebrates. Physiol Rev 2:418–540

Adeghate E, Ponery AS (2002) GABA in the endocrine pancreas: cellular localization and function in normal and diabetic rats. Tissue Cell 34:1–6

Tsai JS, Lin YS, Pan BS, Chen TJ (2006) Antihypertensive peptides and gamma-aminobutyric acid from prozyme 6 facilitated lactic acid bacteria fermentation of soymilk. Process Biochem 41:1282–1288

Zhang H, Yao HY, Chen F (2006) Accumulation of gamma-aminobutyric acid in rice germ using protease. Biosci Biotechnol Biochem 70:1160–1165

Seok JH, Park KB, Kim YH, Bae MO, Lee MK, Oh SH (2008) Production and characterization of kimchi with enhanced levels of gamma-aminobutyric acid. Food Sci Biotechnol 17:940–946

Matsukawa S, Ueno H (2007) Analysis of intron-exon positioning on glutamate decarboxylase and its relation with evolution. J Biol Macromol 7(3):35–48

Komatsuzaki N, Shima J, Kawamoto S, Momose H, Kimura T (2005) Production of γ-aminobutyric acid (GABA) by Lactobacillus paracasei isolated from traditional fermented foods. Food Microbiol 22:497–504

Cho YR, Chang JY, Chang HC (2007) Production of γ-aminobutyric acid (GABA) by Lactobacillus bunchneri: ioslated from Kimchi and its neuroprotective effect on neuronal cells. J Microbiol Biotech 17(1):104–109

Li H, Cao Y (2010) Lactic acid bacterial cell factories for gamma-aminobutyric acid. Amino Acids 39(5):1107–1116

Gangaraju D, Murty VR, Prapulla SG (2014) Probiotic-mediated biotransformation of monosodium glutamate to γ-aminobutyric acid: differential production in complex and minimal media and kinetic modeling. Ann Microbiol 64:229–237

Huang J, Meilh WuH, Lin D (2007) Biosynthesis of γ-aminobutyric acid (GABA) using immobilized whole cells of Lactobacillus brevis. World J Microb Biot 23(6):865–871

Ziar H, Gerard P, Riaz A (2012) Calcium alginate-resistant starch mixed gel improved the survival of Bifidobacterium animalis subsp. lactis Bb12 and Lactobacillus rhamnosus LBRE-LSAS in yogurt and simulated gastrointestinal conditions. Int J Food Sci Tech 47(7):1421–1429

Chen X, Wang XT, Lou WY, Li Y, Wu H, Zong MH, Smith TJ, Chen XD (2012) Immobilization of Acetobacter sp. CCTCC M209061 for efficient asymmetric reduction of ketones and biocatalyst recycling. Microb Cell Fact 11:119

Lewandowski Z and Roe F (1994) Diffusivity of Cu2+ in calcium alginate gel beads: recalculation. Biotechnol Bioeng 43:186–187

Krasaekoopt W, Bhandari B, Deeth H (2003) Evaluation of encapsulation techniques of probiotics for yoghurt. Int Dairy J 13:3–13

Chavarri M, Maranon I, Ares R, Ibanez FC, Marzo F, Villaran MC (2010) Microencapsulation of a probiotic and prebiotic in alginate-chitosan capsules improves survival in simulated gastro-intestinal conditions. Int J Food Microbiol 142:185–189

Acknowledgments

Gangaraju Divyashri is thankful to Council of Scientific and Industrial Research (CSIR), New Delhi, India for the award of Junior Research Fellowship. The Director, CFTRI, is acknowledged for supporting the research work.

Conflict of interest

There is no conflict of interest between the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Divyashri, G., Prapulla, S.G. Mass transfer characterization of gamma-aminobutyric acid production by Enterococcus faecium CFR 3003: encapsulation improves its survival under simulated gastro-intestinal conditions. Bioprocess Biosyst Eng 38, 569–574 (2015). https://doi.org/10.1007/s00449-014-1296-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-014-1296-0